Photoelectric Mixed Connector Assembly

A connector assembly, optoelectronic mixing technology, applied in optical components, light guides, optics, etc., can solve problems such as large optical signal loss, achieve the effect of ensuring performance, solving excessive optical signal loss, and easily ensuring assembly position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

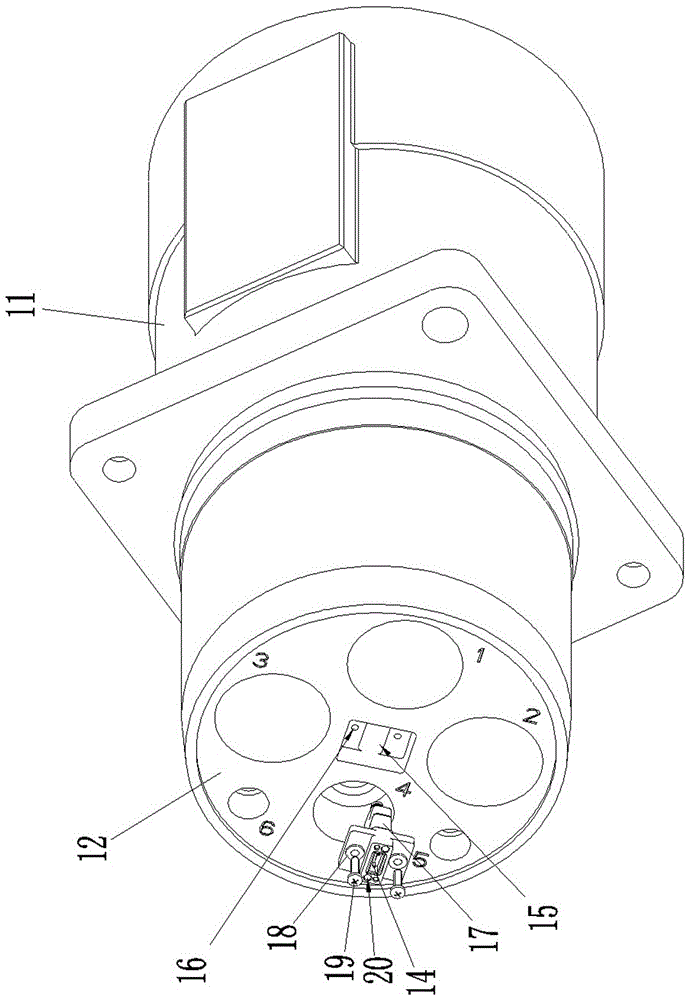

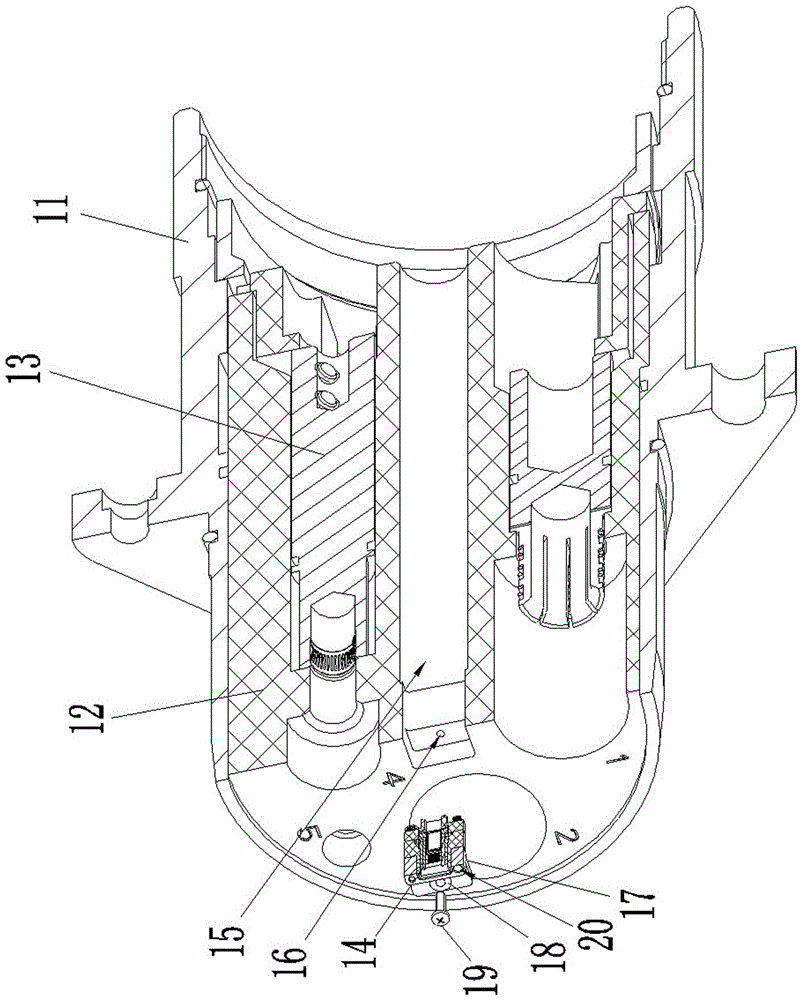

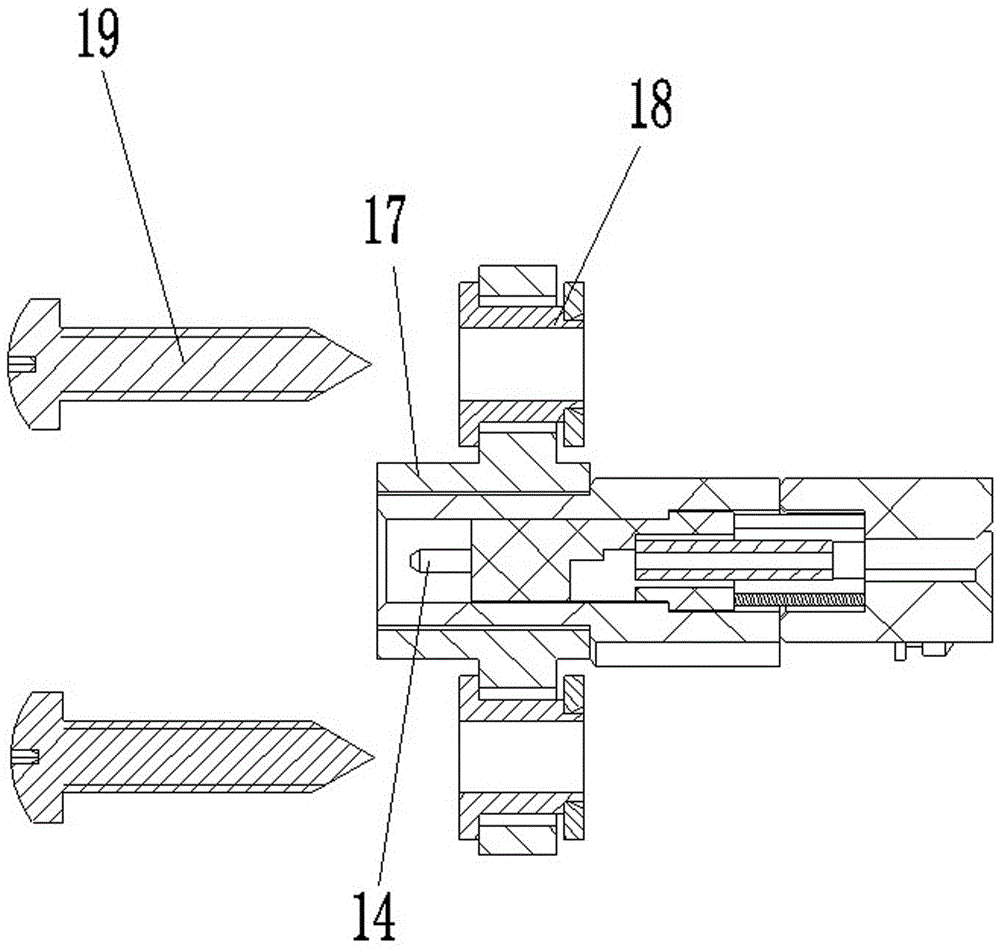

[0020] Embodiments of optoelectronic hybrid connector assemblies, such as Figure 1-8 As shown, the photoelectric hybrid connector assembly includes a plug and a socket.

[0021] The structure of the plug is as Figure 1-4 As shown, it includes a housing 11 , an insulator 12 , an electrical contact 13 and an optical contact 14 .

[0022] The casing 11 is a mounting disk casing, and its structure is in the prior art, so it will not be repeated here.

[0023] The electrical contact 13 is fixedly mounted on the insulator 12. In this embodiment, the electrical contact 13 is a high-current contact, and its structure is in the prior art, so it will not be repeated here. In addition to being equipped with electrical contacts 13, an assembly hole 15 is also provided on the insulator 12, and the assembly hole 15 is used to assemble a corresponding optical connector. In this embodiment, the assembly hole 15 is surrounded by each electrical contact 13 The position between them is spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com