Drum type steel storage tank hydraulic lifting and inverting method based on BIM technology

A hydraulic lifting and storage tank technology, which is applied in the installation of large-scale cylindrical steel storage tanks and large-diameter fields, can solve the problems of broken lifting chucks and uneven synchronization, so as to reduce workload, coordinate on-site work, and ensure assembly Effect of Accuracy Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

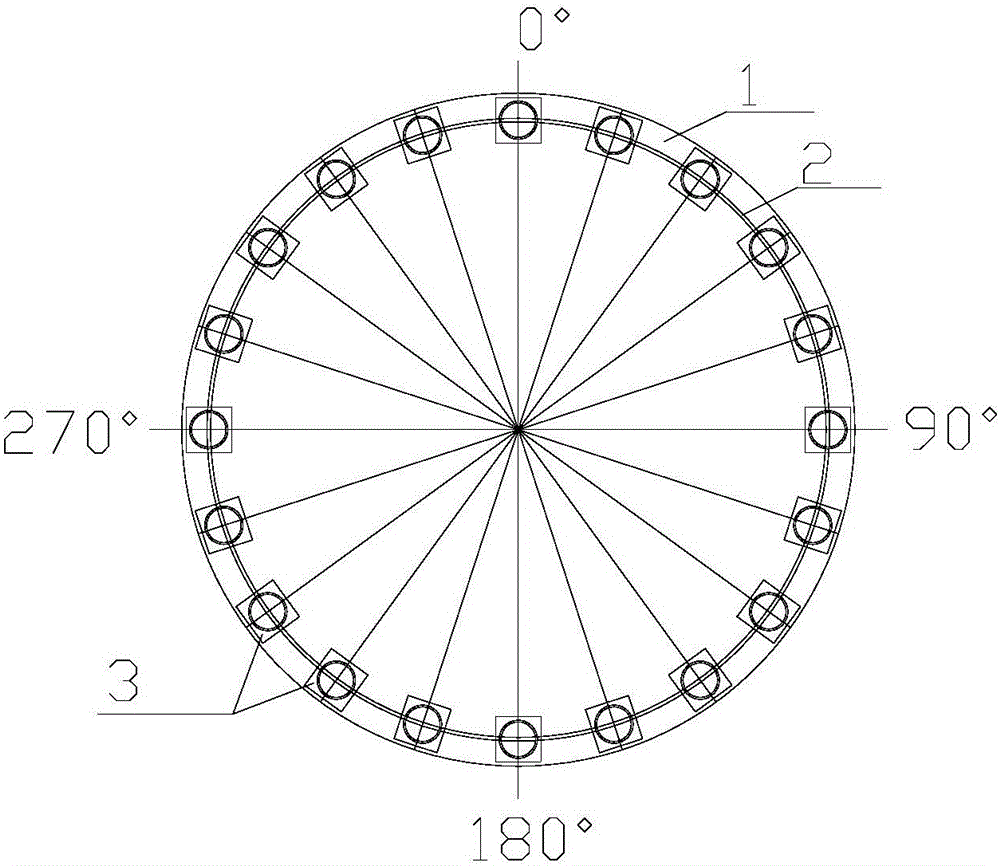

[0033] Step 1: Before the wall plate is assembled, firstly divide the tank bottom plate according to the circumference, and then set a 600mm high Φ325*12 steel pipe support or I50a on the bottom plate along the intersection of the wall plate circumference line and the bottom plate angle bisector line. The top is complemented by a 400mm*400mm*16mm steel plate as an assembly platform 3. And level it with a level gauge, the level error of the support is ≤ 2mm, return the inner circle of the wall plate 2 on the bottom plate 1 vertically to the plane of the support steel plate, set limit baffles on the inner side and the outer side, as a tire for the paired wall plate After the mold support is set up, the geometric dimensions should be rechecked to ensure the diameter of the wall panel. (Assembly platform see attached figure 1 )

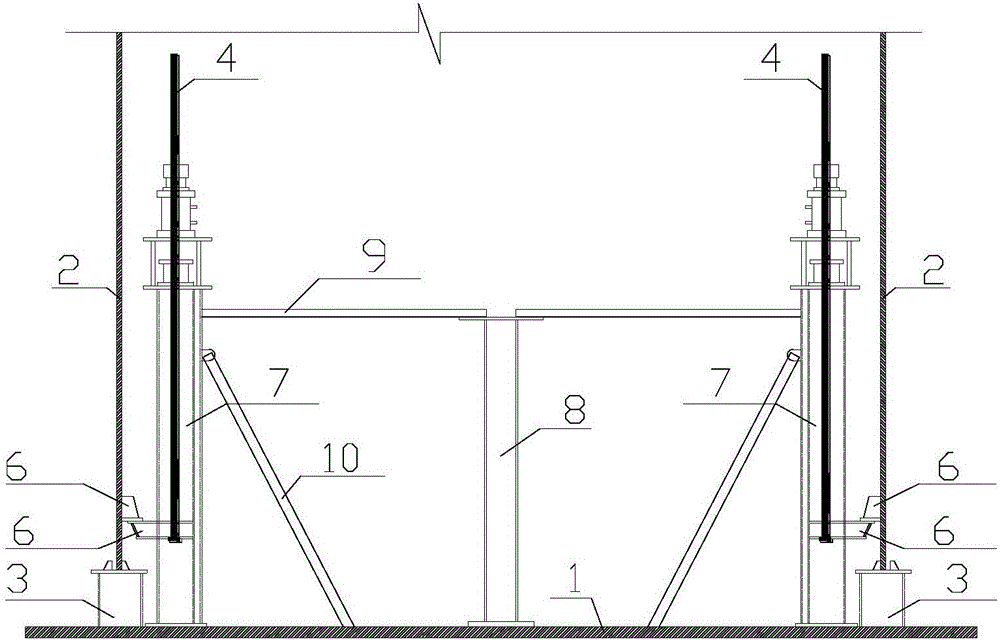

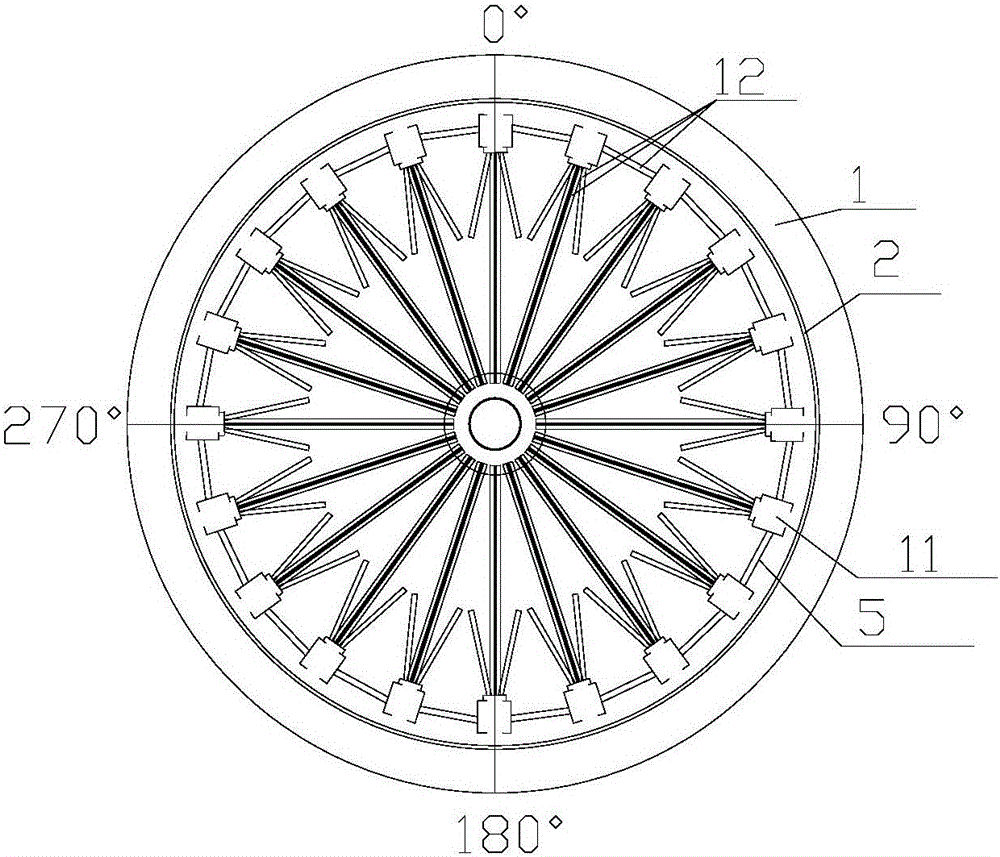

[0034] Step 2: Accurately install the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com