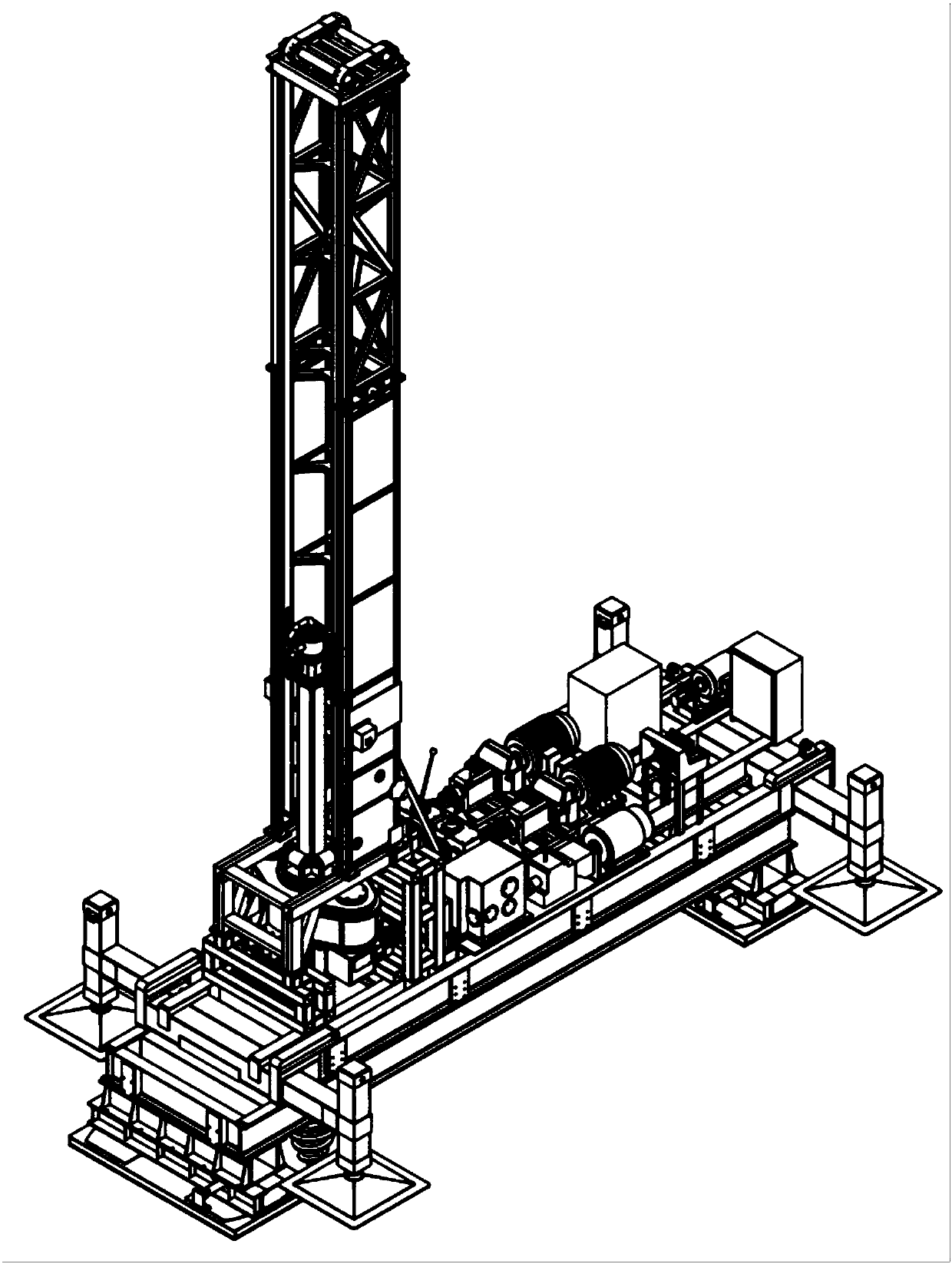

A double-row multi-axle pile machine

A pile driver and frame technology, which is applied in the field of double-row multi-axis pile drivers, can solve problems such as unreported, and achieve the effects of good stability, convenient operation, and reduced structural strength requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Horizontal arrangement of I-shaped tower

[0039] When the I-shaped tower of the double-row multi-axis pile driver of the present invention is arranged horizontally, the pile type can be processed such as Figure 5 Shown, including: "first three after three", "first three after two", "first two after three", "first two after two", "first one after two", "first two after one" or "first one" The double-row pile type with any combination of "the latter" and other types has the beneficial effect of increasing the pile-forming operation and adapting to the maximum possible size requirements of the actual pile spacing array.

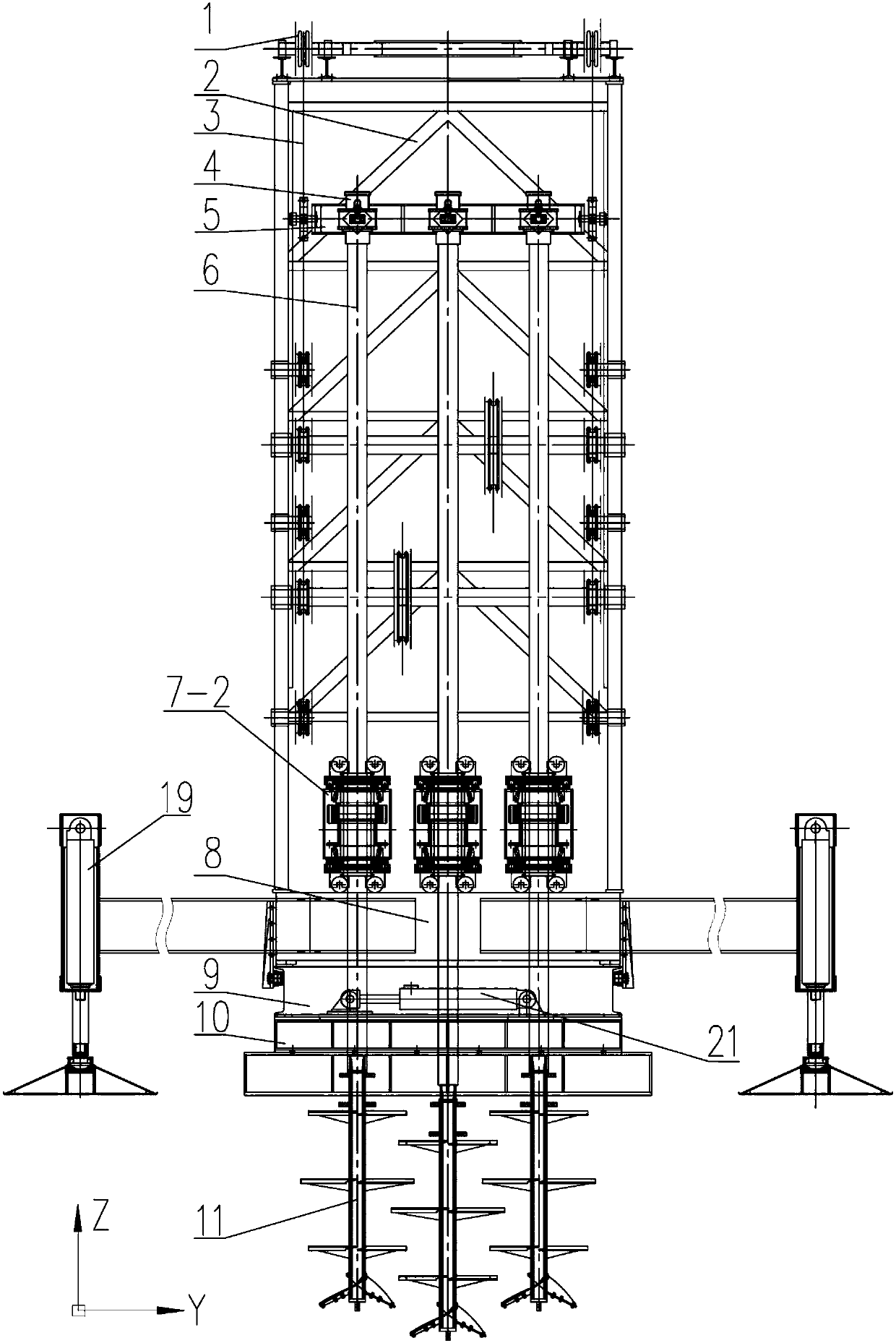

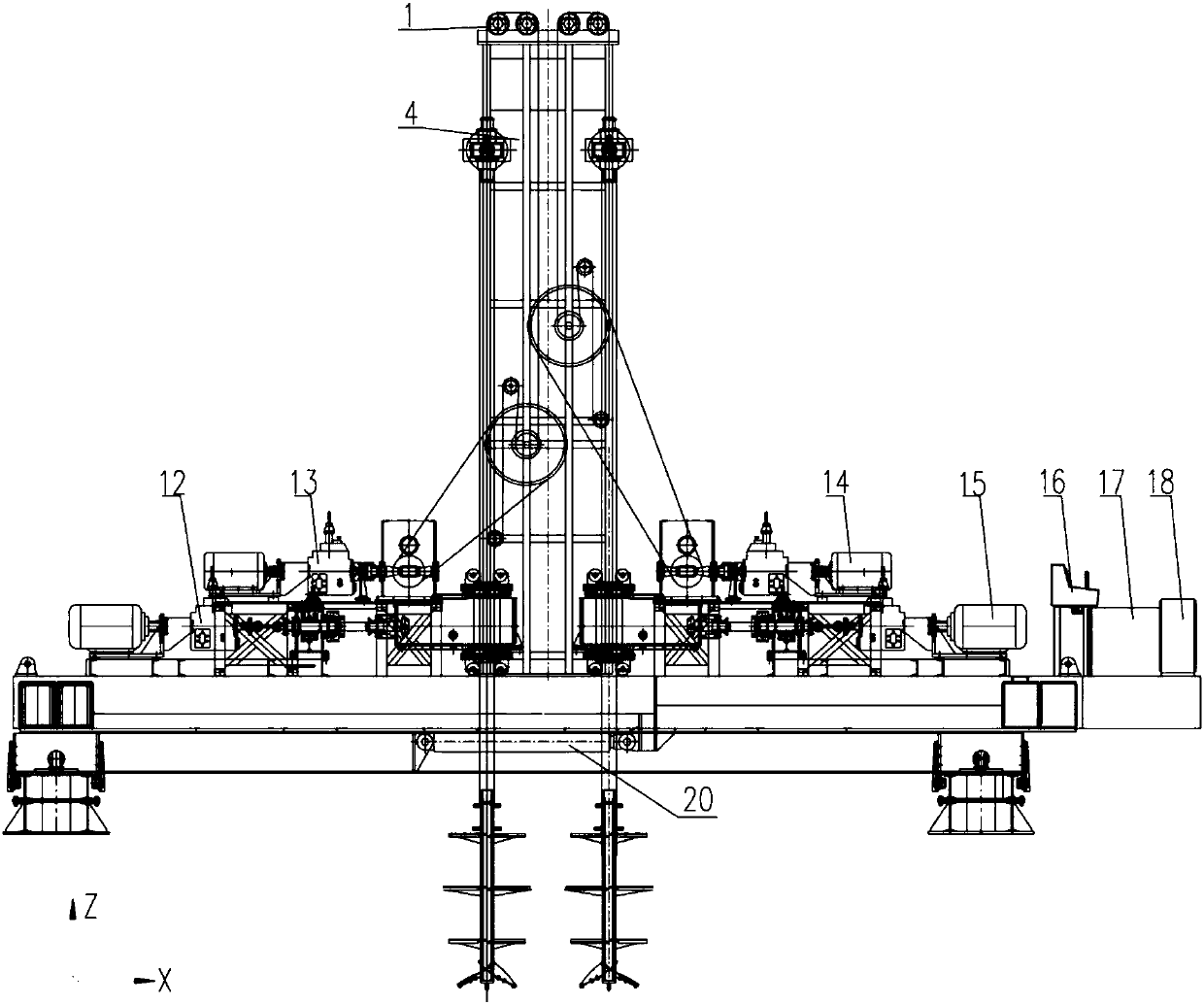

[0040] See attached Figure 2~4 , A double-row multi-axis pile machine, including: sprocket 1, I-shaped tower 2, two sets of lifting chains 3, six rotating heads 4, rotating head frame one 5 and rotating head frame two, six hollow drill rods 6. Six sets of bottom-mounted square turntables, the bottom-mounted square turntables are straight square t...

Embodiment 2

[0054] Example 2: Longitudinal arrangement of I-shaped tower

[0055] See attached Figure 6-8 , When the I-shaped tower 2 is arranged longitudinally, the pile types that can be processed include: "front two back two", "front one back two", "front two back one" or "front one back one" and other arbitrary combinations Double-row pile type.

[0056] The arrangement of the upper frame 8, the lower frame 9, the ram 10, the longitudinal movement cylinder 20, the lateral movement cylinder 21, four supporting legs 19, a set of hydraulic and electric operation table 16, the hydraulic oil tank 17 and the electric control cabinet 18 The first embodiment is the same.

[0057] Setting: The horizontal direction of the double-row multi-axis pile driver is the Y-axis direction, the longitudinal direction is the X-axis direction, and the height is the Z-axis direction; Figure 8 In the illustrated I-shaped tower 2, the neutral plane is parallel to the X axis.

[0058] See attached Figure 6-8 , Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com