Swinging self-resetting dual-deck bridge bent pier based on energy-dissipation angle steel with vertical joints

A self-reset, bent pier technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of long-term occupation of traffic passages, rapid repair of unfavorable structures, loud noise and construction waste, etc., to reduce adverse effects, The effect of facilitating post-earthquake repair and reducing urban congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

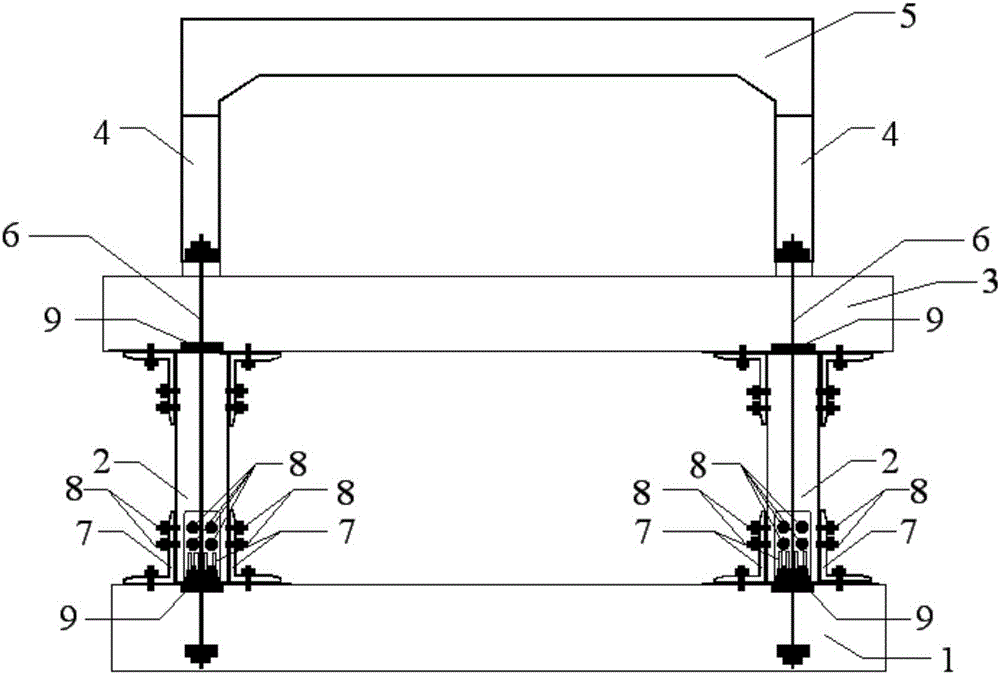

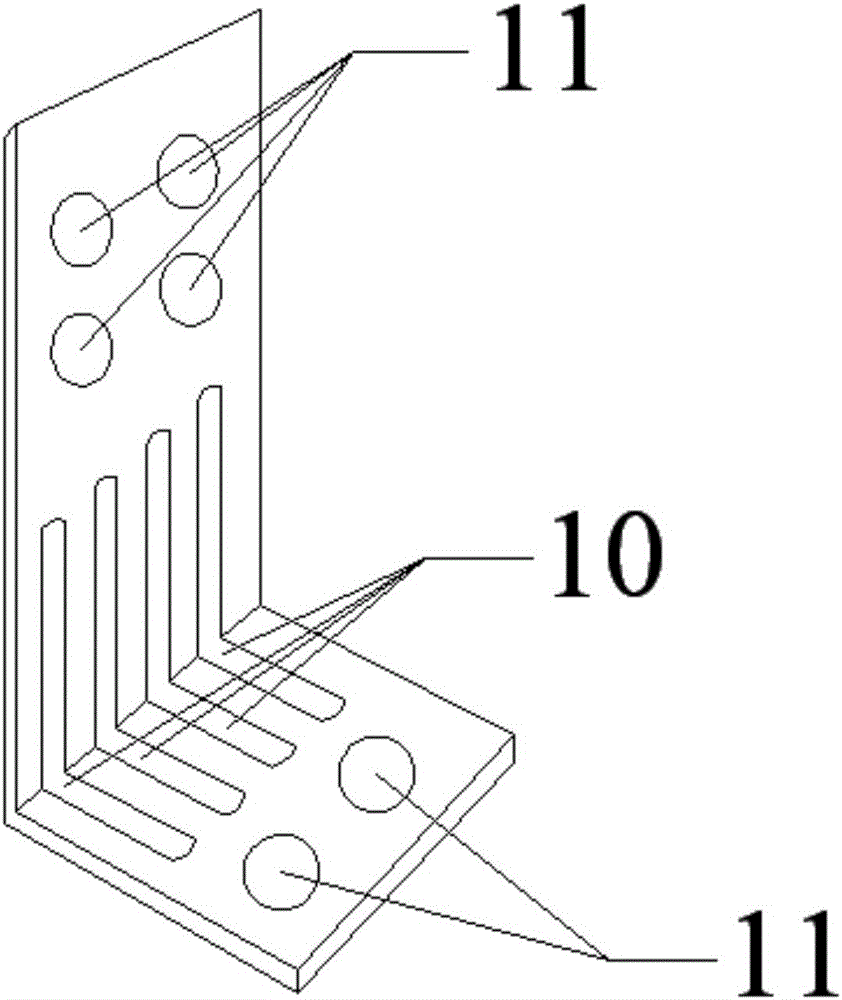

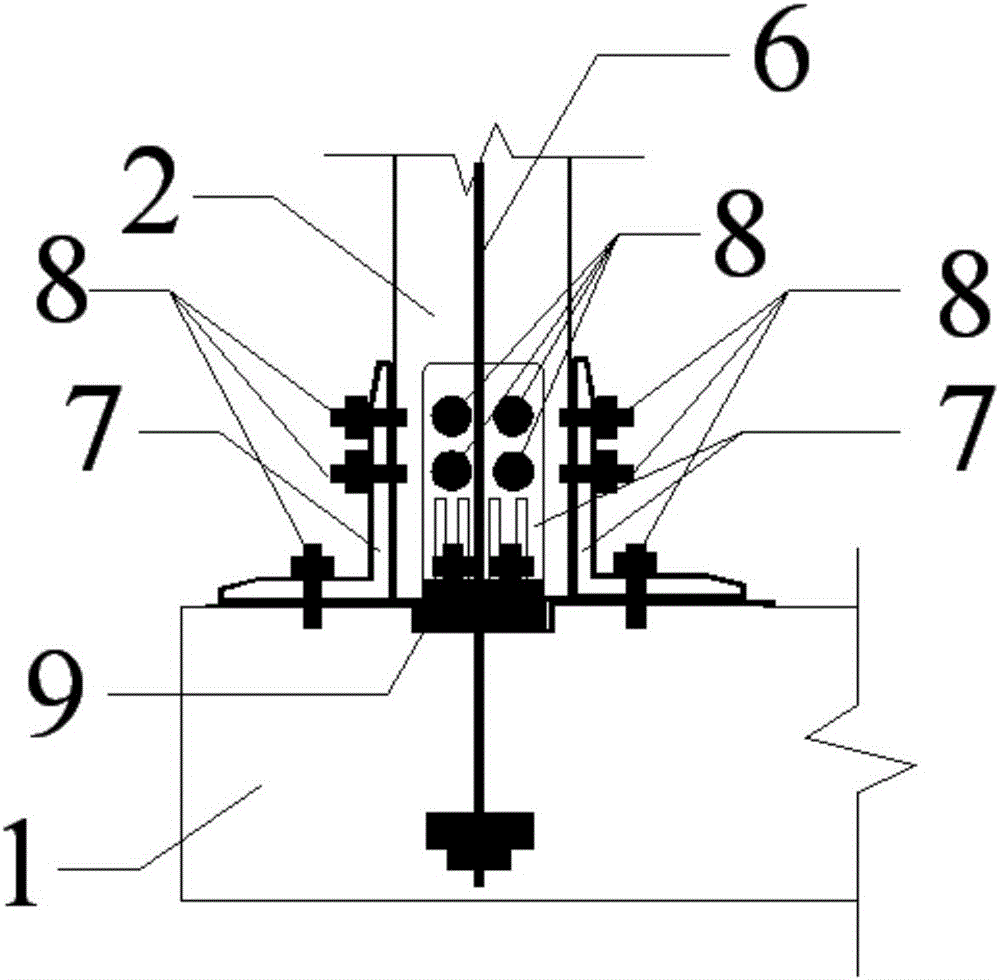

[0036] Such as Figure 1 to Figure 4 A swinging self-resetting double-layer bridge bent pier based on energy-dissipating angle steel with vertical joints is shown, including: the bent pier foundation, and two prefabricated steel tube concrete at the bottom layer on the left and right sides of the bent pier foundation The piers are internally poured with self-compacting steel fiber reinforced concrete. The prefabricated precast cap beams on the ground floor on the top of the prefabricated concrete filled steel pipe piers on the ground floor, the two precast piers on the top floor on the left and right sides above the prefabricated steel pipe concrete Unbonded prestressed tendons of bridge piers with energy-dissipating angles for vertical joints.

[0037] The energy-dissipating angle steel with vertical joints is made of Q235 mild steel with a low yield point. The bottom prefabricated steel pipe concrete pier is connected with the bent pier foundation and the bottom prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com