Chopped basalt fiber reinforced abs resin composite material and its preparation method and application

A technology of basalt fiber and ABS resin is applied in the field of chopped basalt fiber reinforced ABS resin composite material and its preparation field, which can solve the problems of the cost of alkali-resistant carbon fiber and poor gloss of the composite material, and achieve the improvement of yield and good quality. Economic benefits, the effect of narrow length distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

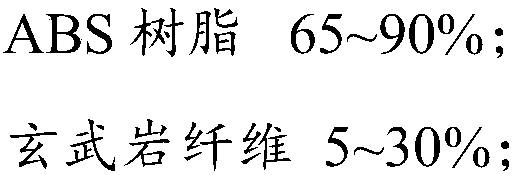

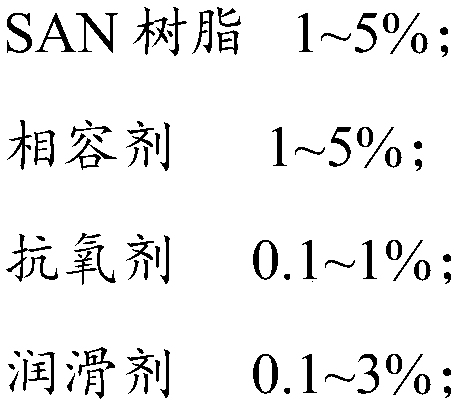

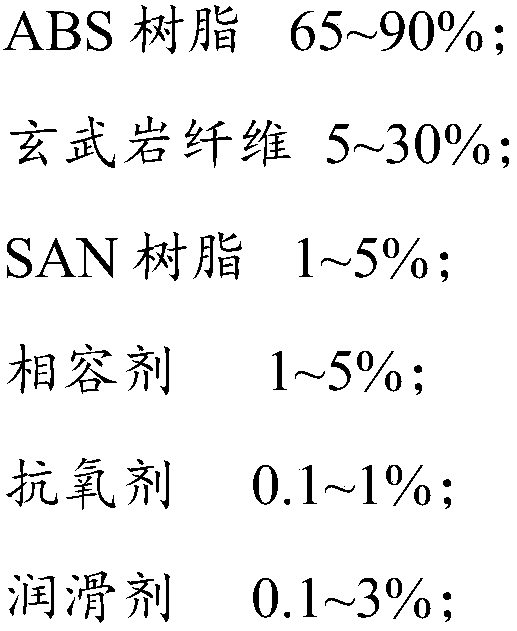

[0040] In one embodiment, the preparation method of the chopped basalt fiber reinforced ABS resin composite material at least includes the following steps, weighing each component according to the above-mentioned formula of the chopped basalt fiber reinforced ABS composite material;

[0041] Mixing the weighed ABS resin, SAN resin, compatibilizer, antioxidant, and lubricant to obtain a mixture;

[0042] Put the basalt fiber into the forced side feeding port of the twin-screw extruder;

[0043] The mixture is put into the twin-screw extruder to melt and co-extrude with the basalt fiber.

[0044] In order to achieve the technical effects of the embodiments of the present invention, a twin screw extruder equipped with forced side feeding equipment is required during the preparation process. If the forced side feeding equipment is not used, mixing the basalt fiber directly from the main feed will cause the basalt fiber to be destroyed into powder during the processing process, losing the ...

Embodiment

[0051] To save space, the formula components of each example are listed in Table 1.

[0052] Table 1 Formulations of Examples and Comparative Examples

[0053]

[0054] Among them, the components of Table 1 are described as follows:

[0055] A ABS resin general purpose ABS resin impact strength 25KJ / m 2 ;

[0056] B AS resin high flow AS resin melt index> 70g / 10min molecular weight 20000.

[0057] C basalt fiber:

[0058] C1 chopped basalt fiber has a diameter of 16μm and a chopped length of 6mm;

[0059] C2 continuous basalt fiber has a diameter of 16μm, continuous long fiber.

[0060] D Compatibilizer:

[0061] D1 styrene-maleic anhydride random copolymer;

[0062] D2 styrene-acrylonitrile-maleic anhydride ternary random copolymer;

[0063] D3 styrene-acrylonitrile-glycidyl methacrylate ternary random copolymer.

[0064] E antioxidant: B215 antioxidant 1010:168=1:2.

[0065] F lubricant: EBS.

[0066] G toner: carbon black.

[0067] For Examples 1-6, the ingredients were weighed according to Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com