Method for preparing slow-release fertilizer from lignocellulose ethanol fermentation residues

A lignocellulose and ethanol fermentation technology, applied in the direction of calcium fertilizer, inorganic fertilizer, urea compound fertilizer, etc., can solve the problems of soil secondary pollution, poor slow-release effect, complicated process, etc. Promotion of agricultural and forestry fertilization patterns, the effect of simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

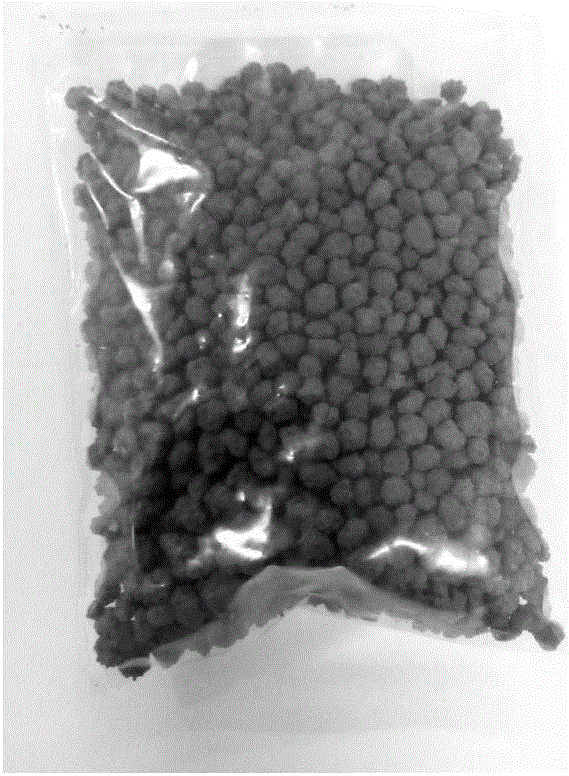

Image

Examples

Embodiment 1

[0044] Lignocellulosic ethanol fermentation residues are dried and pulverized, and passed through a 100-mesh sieve for later use. Take 20g of dried and pulverized lignocellulose ethanol fermentation residue into a 500mL three-neck flask, add 80mL of pure water for mixing, use NaOH solution to adjust the pH to 8.0, and place it in an ultrasonic cleaner for 6 hours.

[0045] In the three-neck flask containing the lignocellulose ethanol fermentation residue solution, 5 g of formaldehyde solution was slowly added dropwise, and mechanically stirred for 6 hours in a constant temperature water bath at 90°C.

[0046] Slowly add 10 g of polyvinyl alcohol (AH-26, alcoholysis degree: 98%) into 90 mL of pure water, stir rapidly while adding, and gradually raise the temperature from room temperature to 40°C.

[0047] The polyvinyl alcohol solution is slowly added dropwise to the lignocellulosic ethanol fermentation residue and formaldehyde solution, in a water bath at 90° C., and mechanica...

Embodiment 2

[0052]Lignocellulosic ethanol fermentation residues are dried and pulverized, and passed through a 100-mesh sieve for later use. Take 20g of dried and pulverized lignocellulose ethanol fermentation residue into a 500mL three-neck flask, add 80mL of pure water for mixing, use NaOH solution to adjust the pH to 8.0, and place it in an ultrasonic cleaner for 6 hours.

[0053] Add 5 g of acetic anhydride to a three-neck flask containing the solution of lignocellulosic ethanol fermentation residue, and mechanically stir for 6 h in a constant temperature water bath at 90°C.

[0054] Slowly add 10 g of polyvinyl alcohol (AH-26, alcoholysis degree: 98%) into 90 mL of pure water, stir rapidly while adding, and gradually raise the temperature from room temperature to 40°C.

[0055] The polyvinyl alcohol solution is slowly added dropwise to the lignocellulosic ethanol fermentation residue and formaldehyde solution, in a water bath at 90° C., and mechanically stirred for 10 hours to obtain...

Embodiment 3

[0060] Lignocellulosic ethanol fermentation residues are dried and pulverized, and passed through a 100-mesh sieve for later use. Take 20g of dried and pulverized lignocellulose ethanol fermentation residue into a 500mL three-neck flask, add 80mL of pure water for mixing, use NaOH solution to adjust the pH to 8.0, and place it in an ultrasonic cleaner for 6 hours.

[0061] In the three-neck flask containing the lignocellulose ethanol fermentation residue solution, 5 g of formaldehyde solution was slowly added dropwise, and mechanically stirred for 6 hours in a constant temperature water bath at 90°C.

[0062] Slowly add 10 g of polyvinyl alcohol (AH-26, alcoholysis degree: 98%) into 90 mL of pure water, stir rapidly while adding, and gradually raise the temperature from room temperature to 40°C.

[0063] The polyvinyl alcohol solution is slowly added dropwise to the lignocellulosic ethanol fermentation residue and formaldehyde solution, in a water bath at 90° C., and mechanica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com