Special biological slow-release compound fertilizer for cotton and production method of compound fertilizer through melt granulation in high prilling tower

A cotton and biological technology, applied in the direction of urea compound fertilizer, application, nitrogen fertilizer, etc., can solve the problem of low nutrient utilization rate, achieve the effect of enhancing Verticillium wilt resistance, comprehensive nutrition, and improving traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

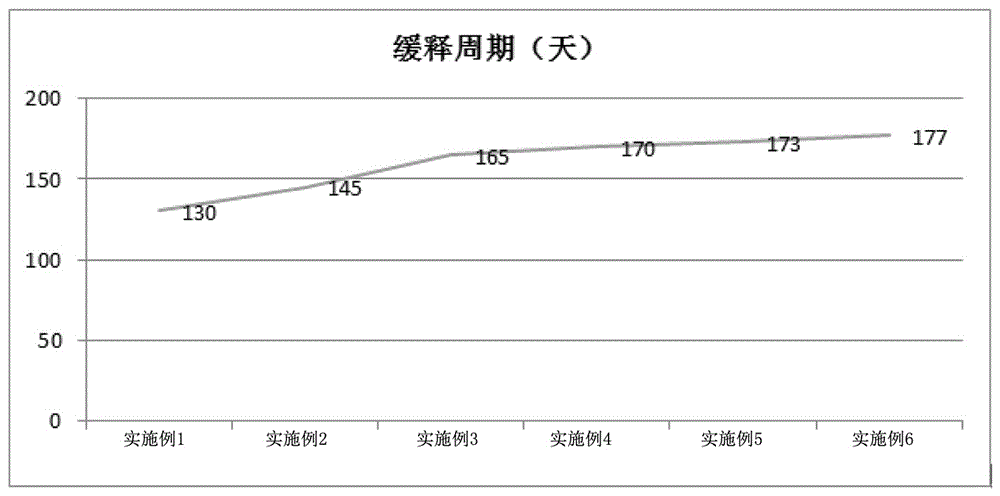

Embodiment 1

[0024] 310 parts of urea, 330 parts of potassium chloride, 180 parts of monoammonium phosphate, 120 parts of biological humic acid, 30 parts of heavy superphosphate, and 10 parts of chelated trace elements are sent to the prilling tower equipment after metering. After the 1# mixing tank reactor was chelated at 140°C, a slurry with good fluidity was formed. During the 2# reactor chelation process, 15 parts of nano-carbon and 4.8 parts of sodium borate were added at the 110°C stage, and sprayed into granules through a granulator. After the granules are cooled in a high tower (100°C is reduced to about 45°C), 0.2 parts of polyvinyl alcohol (PVA) is added in the fluidized bed granule coating stage to obtain a special biological slow-release compound fertilizer for cotton.

Embodiment 2

[0026] 310 parts of urea, 330 parts of potassium chloride, 180 parts of monoammonium phosphate, 110 parts of biological humic acid, 30 parts of heavy superphosphate, and 10 parts of chelated trace elements are sent to the prilling tower equipment after metering. After the 1# mixing tank reactor was chelated at 140°C, a slurry with good fluidity was formed. In the 2# reactor chelation process, 25 parts of nano-carbon and 4.8 parts of sodium borate were added at the 110°C stage, and sprayed into granules through a granulator. After the granules are cooled in a high tower (100°C is reduced to about 45°C), 0.2 parts of polyvinyl alcohol (PVA) is added in the fluidized bed granule coating stage to obtain a special biological slow-release compound fertilizer for cotton.

Embodiment 3

[0028] 310 parts of urea, 330 parts of potassium chloride, 180 parts of monoammonium phosphate, 100 parts of biological humic acid, 30 parts of heavy superphosphate, and 10 parts of chelated trace elements are sent to the prilling tower equipment after metering. After the 1# mixing tank reactor is chelated at 140°C, a slurry with good fluidity is formed. During the chelation process of the 2# reactor at 110°C, 35 parts of nano-carbon and 4.8 parts of sodium borate are added, and the granulator is sprayed into granules. After the granules are cooled in a high tower (100°C is reduced to about 45°C), 0.2 parts of polyvinyl alcohol (PVA) is added in the fluidized bed granule coating stage to obtain a special biological slow-release compound fertilizer for cotton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com