Green concrete prefabricated pile for strengthening soft foundation and construction method

A technology of concrete prefabricated piles and weak foundations, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of impermeability, freeze-thaw resistance, poor corrosion resistance, necking, backward technology, etc., and achieve simplified piles Production process, improve corrosion resistance and durability, solve the effect of complex production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

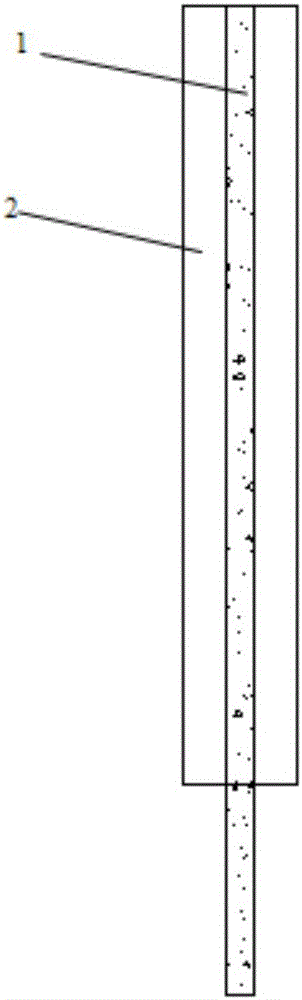

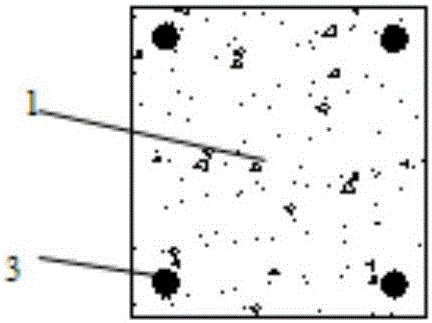

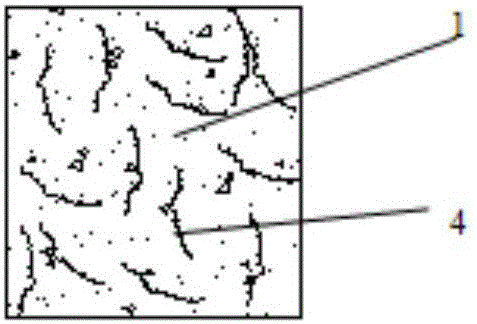

[0053] A green concrete prefabricated pile 1 for strengthening weak foundations, using a base material, and imitation steel fibers 4 are arranged in the base material as tensile reinforcement materials, and the concrete prefabricated pile is made into a concrete prefabricated pile through processes such as formwork support, stirring, pouring molding, and high-temperature autoclaved curing , used to reinforce weak foundations.

[0054] The green concrete prefabricated pile used for strengthening weak foundations, the ratio of the base material is calculated in parts by weight, and is prepared from the raw materials of the following components: 100 parts of fly ash, 20 parts of quicklime, 25 parts of blast furnace slag powder 2 parts, 2 parts of sulfoaluminate cement, 4 parts of sodium sulfate, 5 parts of silica powder, 2 parts of water reducing agent, 0.3 parts of activator, 500 parts of recycled concrete waste aggregate, 70 parts of water, and the tensile reinforcement material...

Embodiment 2

[0065] A green concrete prefabricated pile 1 for strengthening weak foundations, using a base material, and imitation steel fibers 4 are arranged in the base material as tensile reinforcement materials, and the concrete prefabricated pile is made into a concrete prefabricated pile through processes such as formwork support, stirring, pouring molding, and high-temperature autoclaved curing , used to reinforce weak foundations.

[0066] The green concrete prefabricated piles for strengthening weak foundations, the ratio of the base material is calculated by weight, and is prepared from the raw materials of the following components: 80 parts of fly ash, 15 parts of quicklime, 20 parts of blast furnace slag powder 3 parts, 3 parts of sulfoaluminate cement, 2 parts of sodium sulfate, 1 part of microsilica powder, 0.3 parts of superplasticizer, 0.1 part of activator, 230 parts of recycled aggregate for concrete waste, and 45 parts of water.

[0067] The cross section of the concrete...

Embodiment 3

[0075] A green concrete prefabricated pile 1 for strengthening weak foundations, using a base material, and imitation steel fibers 4 are arranged in the base material as tensile reinforcement materials, and the concrete prefabricated pile is made into a concrete prefabricated pile through processes such as formwork support, stirring, pouring molding, and high-temperature autoclaved curing , used to reinforce weak foundations.

[0076] The green concrete prefabricated pile used for strengthening weak foundations, the ratio of the base material is calculated in parts by weight, and is prepared from the raw materials of the following components: 90 parts of fly ash, 20 parts of quicklime, 25 parts of blast furnace slag powder 2 parts, 2 parts of sulfoaluminate cement, 3 parts of sodium sulfate, 3 parts of silica powder, 1 part of water reducing agent, 0.3 parts of activator, 220 parts of recycled construction waste aggregate, and 68 parts of water.

[0077] The cross section of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com