Method for preparing mesoporous TS-1 titanium silicalite molecular sieves through hydrothermal crystallization method

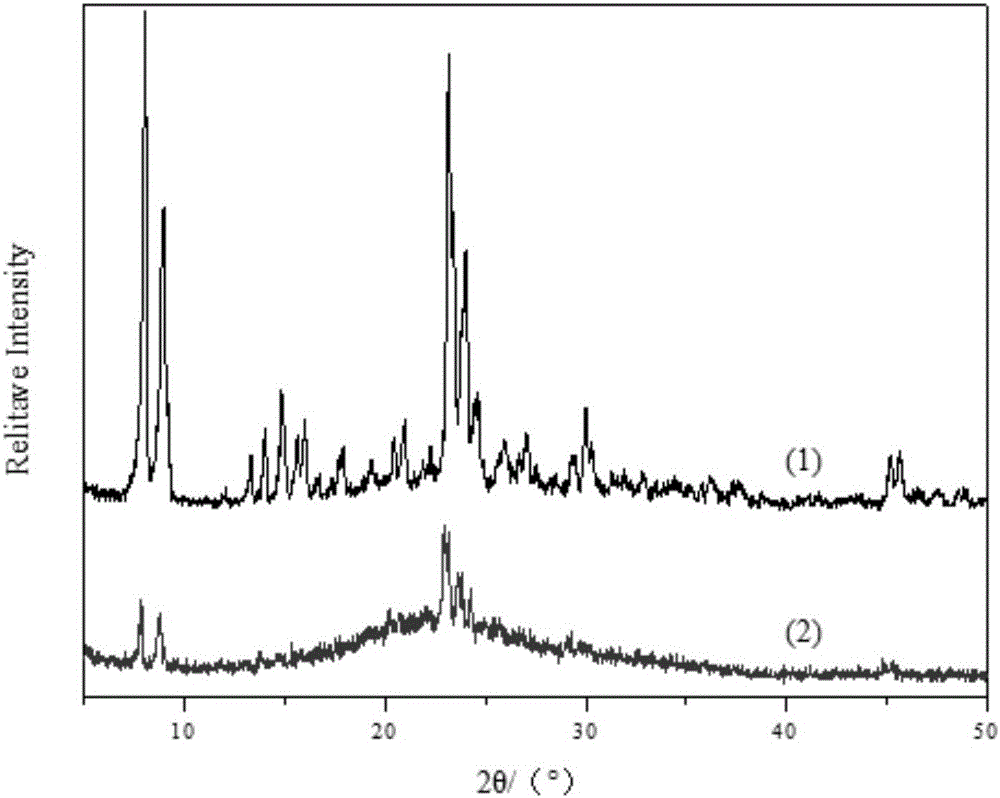

A titanium-silicon molecular sieve and hydrothermal crystallization technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of high production cost of titanium-silicon molecular sieve, low content of framework titanium, complicated preparation method, etc., so as to reduce the concentration of anatase. The effect of generation, high content of skeleton titanium and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

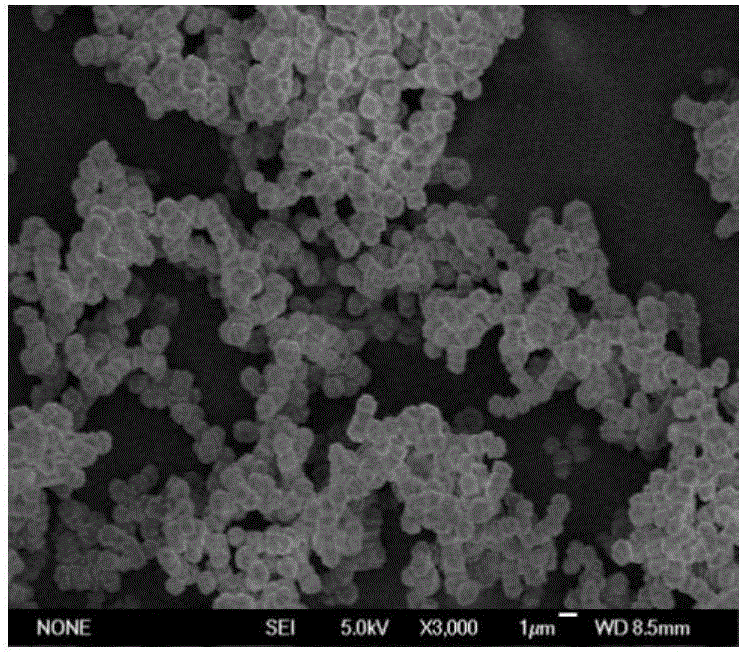

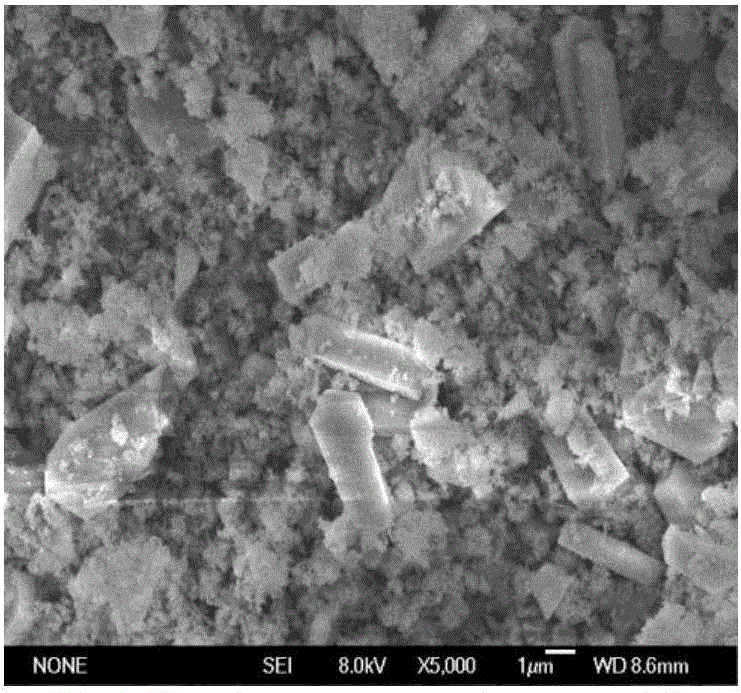

Embodiment 1

[0032] At 25°C, first mix tetrapropylammonium bromide, tetraethyl orthosilicate, and water to form A; mix the pore expander with water to form B; add emulsifier TX-10 to butyl titanate to form emulsion C; Pass inert gas into the emulsion C and use the shock generated by the bubble burst to demulsify the emulsion to release the titanium source; then mix A and B and drop them into C to form D, and use tetramethyl hydroxide during the dropwise addition Adjust the pH value with ammonium to make the pH value = 12. After the titration is completed, place D in a stainless steel crystallization reaction kettle for crystallization at 170°C for 48 hours, filter and wash the resulting crystallized product, and dry 6 pieces at 120°C. Hours, calcined at 550°C for 6 hours to obtain a large-diameter TS-1 molecular sieve. Among them, tetraethyl orthosilicate: emulsifier (TX-10): butyl titanate: tetrapropylammonium bromide: pore expander (hexamethyleneimine): the molar ratio of water is 1:0.06...

Embodiment 2

[0034] At 25°C, tetrapropylammonium bromide, tetraethyl orthosilicate, and water are first mixed to form A; the pore expander is mixed with water to form B; the emulsifier acetylacetone is added to butyl titanate to form emulsion C; The inert gas is introduced into the emulsion C, and the shock generated by the bursting of the bubbles is used to demulsify the emulsion to release the titanium source; then A and B are mixed and dropped into C to form D, and tetramethyl hydroxide is used during the dropwise addition process. Adjust the pH value with ammonium to make the pH value = 12. After the titration is completed, place D in a stainless steel crystallization reaction kettle for crystallization at 170°C for 60 hours, filter and wash the resulting crystallized product, and dry 5 pieces at 120°C. Hours, calcined at 550°C for 5 hours to obtain a large-diameter TS-1 molecular sieve. Among them, ethyl orthosilicate: emulsifier acetylacetone: butyl titanate: tetrapropylammonium brom...

Embodiment 3

[0036] At 25°C, first mix tetrapropylammonium bromide, propyl orthosilicate, and water to form A; mix the pore expander with water to form B; add emulsifier TX-10 to butyl titanate to form emulsion C; Pass inert gas into the emulsion C and use the shock generated by the bursting of the bubbles to break the emulsion to release the titanium source; then mix A and B and drop them into C to form D, and use tetramethyl hydrogen in the process of dropping Adjust the pH value with ammonium oxide to make the pH value = 12. After the titration is completed, place D in a stainless steel crystallization reactor and crystallize at 170°C for 60 hours. Filter and wash the obtained crystallized product, and dry it at 120°C for 60 hours. hour, and roasted at 550°C for 6 hours to obtain a large-diameter TS-1 molecular sieve. Among them, propyl orthosilicate: emulsifier TX-10: butyl titanate: tetrapropylammonium bromide: pore expander (trimethylbenzene): the molar ratio of water is 1:0.06:0.06:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com