Method for preparing mesoporous ts-1 titanium-silicon molecular sieve by hydrothermal crystallization

A titanium-silicon molecular sieve and hydrothermal crystallization technology, applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of high production cost of titanium-silicon molecular sieve, cumbersome preparation method, low content of framework titanium, etc. The generation and preparation methods are simple, and the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

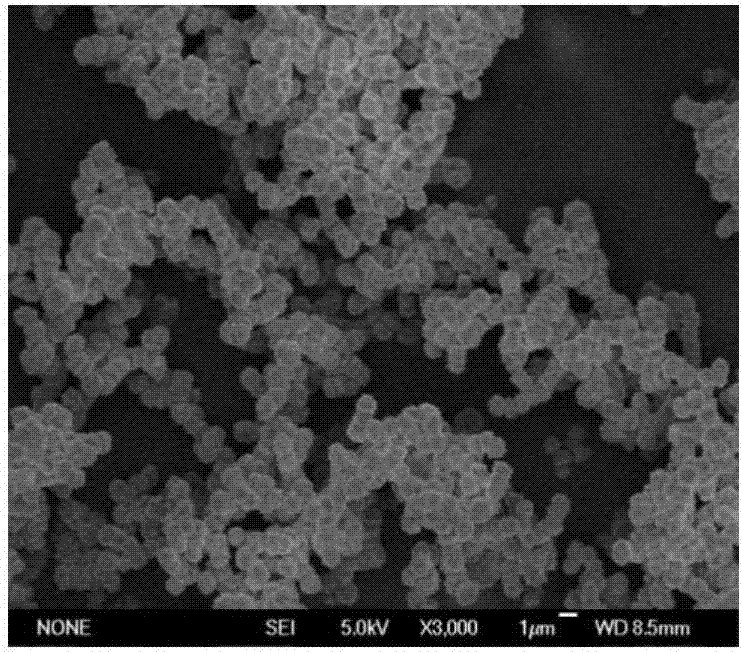

Image

Examples

Embodiment 1

[0032] At 25°C, first mix tetrapropylammonium bromide, tetraethyl orthosilicate, and water to form A; mix the pore expander with water to form B; add emulsifier TX-10 to butyl titanate to form emulsion C; Pass inert gas into the emulsion C and use the shock generated by the bubble burst to demulsify the emulsion to release the titanium source; then mix A and B and drop them into C to form D, and use tetramethyl hydroxide during the dropwise addition Adjust the pH value with ammonium to make the pH value = 12. After the titration is completed, place D in a stainless steel crystallization reaction kettle for crystallization at 170°C for 48 hours, filter and wash the resulting crystallized product, and dry 6 pieces at 120°C. Hours, calcined at 550°C for 6 hours to obtain a large-diameter TS-1 molecular sieve. Among them, tetraethyl orthosilicate: emulsifier (TX-10): butyl titanate: tetrapropylammonium bromide: pore expander (hexamethyleneimine): the molar ratio of water is 1:0.06...

Embodiment 2

[0034] At 25°C, tetrapropylammonium bromide, tetraethyl orthosilicate, and water are first mixed to form A; the pore expander is mixed with water to form B; the emulsifier acetylacetone is added to butyl titanate to form emulsion C; The inert gas is introduced into the emulsion C, and the shock generated by the bursting of the bubbles is used to demulsify the emulsion to release the titanium source; then A and B are mixed and dropped into C to form D, and tetramethyl hydroxide is used during the dropwise addition process. Adjust the pH value with ammonium to make the pH value = 12. After the titration is completed, place D in a stainless steel crystallization reaction kettle for crystallization at 170°C for 60 hours, filter and wash the resulting crystallized product, and dry 5 pieces at 120°C. Hours, calcined at 550°C for 5 hours to obtain a large-diameter TS-1 molecular sieve. Among them, ethyl orthosilicate: emulsifier acetylacetone: butyl titanate: tetrapropylammonium brom...

Embodiment 3

[0036] At 25°C, first mix tetrapropylammonium bromide, propyl orthosilicate, and water to form A; mix the pore expander with water to form B; add emulsifier TX-10 to butyl titanate to form emulsion C; Pass inert gas into the emulsion C and use the shock generated by the bursting of the bubbles to break the emulsion to release the titanium source; then mix A and B and drop them into C to form D, and use tetramethyl hydrogen in the process of dropping Adjust the pH value with ammonium oxide to make the pH value = 12. After the titration is completed, place D in a stainless steel crystallization reactor and crystallize at 170°C for 60 hours. Filter and wash the obtained crystallized product, and dry it at 120°C for 60 hours. hour, and roasted at 550°C for 6 hours to obtain a large-diameter TS-1 molecular sieve. Among them, propyl orthosilicate: emulsifier TX-10: butyl titanate: tetrapropylammonium bromide: pore expander (trimethylbenzene): the molar ratio of water is 1:0.06:0.06:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com