A circular hoisting tool

A hoisting tool and hoisting part technology, used in cranes and other directions, can solve the problems of large base occupied space, single use range, long power failure cycle, etc., to achieve the effect of improving work efficiency, reducing power failure range and reducing power failure cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

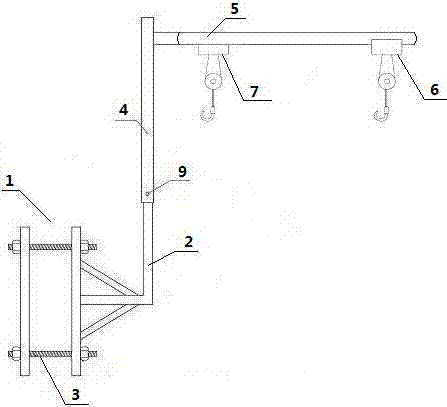

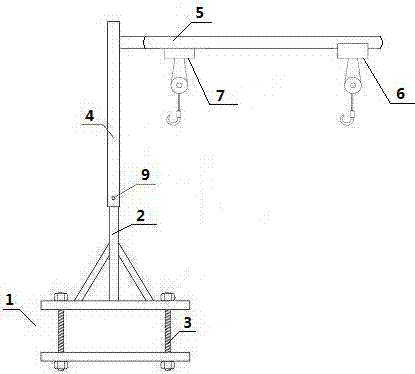

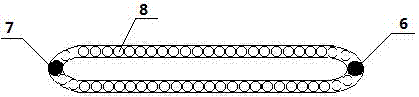

[0024] Example one: figure 1 , image 3 As shown, a schematic structural diagram of a circulating hoisting tool of the present invention includes a supporting part and a hoisting part. The supporting part includes a base 1 and a first main rod 2 fixed on the base 1. The base 1 is provided with an adjustable The bolt 3 is composed of two steel plates. The hoisting part includes a second main rod 4 and a cantilever 5. The second main rod 4 and the first main rod 2 are sleeved together to connect the two parts, and the cantilever 5 is fixedly connected to The upper end of the second main rod 4 and the second main rod 5 are at an angle of 90°. The cantilever 5 has an annular shape and is provided with a guide rail. The guide rail is provided with a first electric hoist 6 and a second The electric hoist 7 can slide on the cantilever 5, and a steel ball 8 is installed in the gap between the first electric hoist 6 and the second electric hoist 7 on the guide rail.

[0025] Figure 4 As ...

Embodiment 2

[0035] Embodiment two: figure 2 As shown, a schematic structural diagram of a circulating hoisting tool of the present invention includes a supporting part and a hoisting part. The supporting part includes a base 1 and a first main rod 2 fixed on the base 1. The base 1 is provided with an adjustable The bolt 3 is composed of two steel plates. The hoisting part includes a second main rod 4 and a cantilever 5. The second main rod 4 and the first main rod 2 are sleeved together to connect the two parts, and the cantilever 5 is fixedly connected to The upper end of the second main rod 4 and the second main rod 5 are at an angle of 90°. The cantilever 5 has an annular shape and is provided with a guide rail. The guide rail is provided with a first electric hoist 6 and a second The electric hoist 7 can slide on the cantilever 5, and a steel ball 8 is installed in the gap between the first electric hoist 6 and the second electric hoist 7 on the guide rail.

[0036] Figure 5 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com