Unattended operation control system and method for mine vertical shaft hoist

A control system and hoist technology, applied in the direction of lifting equipment, elevators, transportation and packaging in mines, can solve the problems of ineffective protection of mechanical equipment, enterprise losses, poor anti-interference ability, etc., to reduce staffing, reduce The effect of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

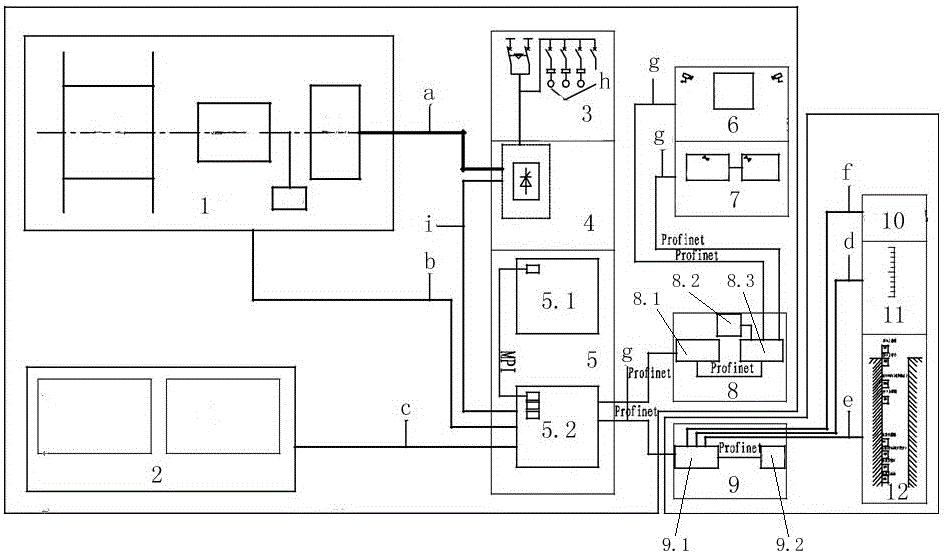

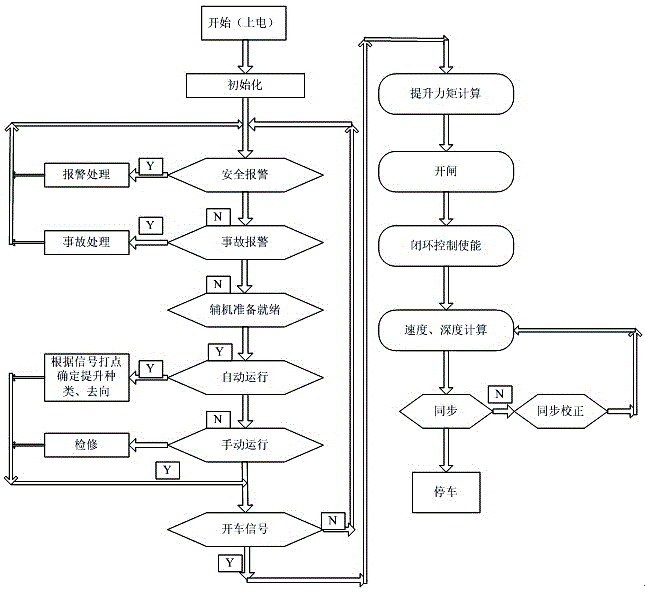

[0042] Such as figure 1 As shown, an unattended control system for a mine shaft hoist includes a host system, an auxiliary machine system, a power distribution system, a transmission system, a PLC control system, a machine room monitoring platform, a wellhead console, a mine hoist depth indicator device, The system fault push system and industrial audio and video monitoring system, PLC control system are respectively connected with the main engine system, auxiliary engine system, transmission system, machine room monitoring platform and wellhead console, the main engine system and the transmission system are connected by cables, and the transmission system and power distribution System connection, the wellhead console is connected with the depth indicator device of the mine hoist, and the monitoring platform of the machine room is respectively connected with the system fault push system and the industrial audio and video monitoring system.

[0043] Power distribution system: s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com