A semi-automatic roll changing device and method for squeezing dry rolls

A roll changing device and a technology for squeezing dry rolls, applied in the field of cold rolling mills, can solve the problems of large resistance, large workload, manual disassembly and assembly, etc., and achieve the effect of increasing space, reducing the input of manual labor, and making production activities comfortable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

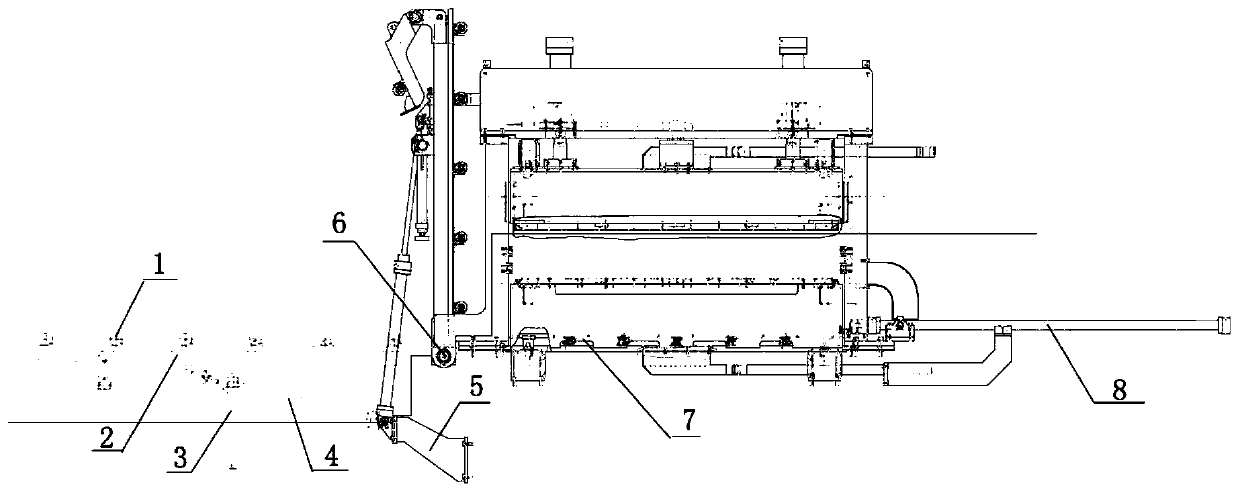

[0059] In the following, a semi-automatic roll changing device and method for a squeezing roll of the present invention will be further described in detail according to the accompanying drawings and specific implementation methods.

[0060] Such as figure 1 , 2 A semi-automatic roll changing device for squeezing rollers shown in 3 and 4 is characterized in that it includes a push-out mechanism for squeezing rollers, an inner rail assembly and an outer rail assembly of the frame for the operation of the squeezing roller,

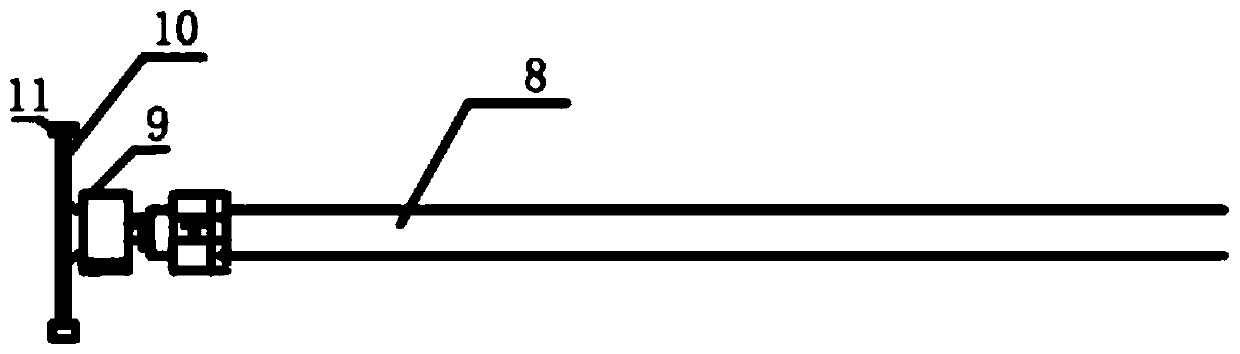

[0061] The push-out mechanism for the squeezing roller includes: a hydraulic cylinder (8), a grapple (10) connected to the hydraulic cylinder and a roller (11) arranged at the end of the grapple;

[0062] The frame inner track assembly for the operation of the squeezing roller includes: a frame inner track (7) and several support wheel sets (1) symmetrically and equidistantly arranged on the frame inner track;

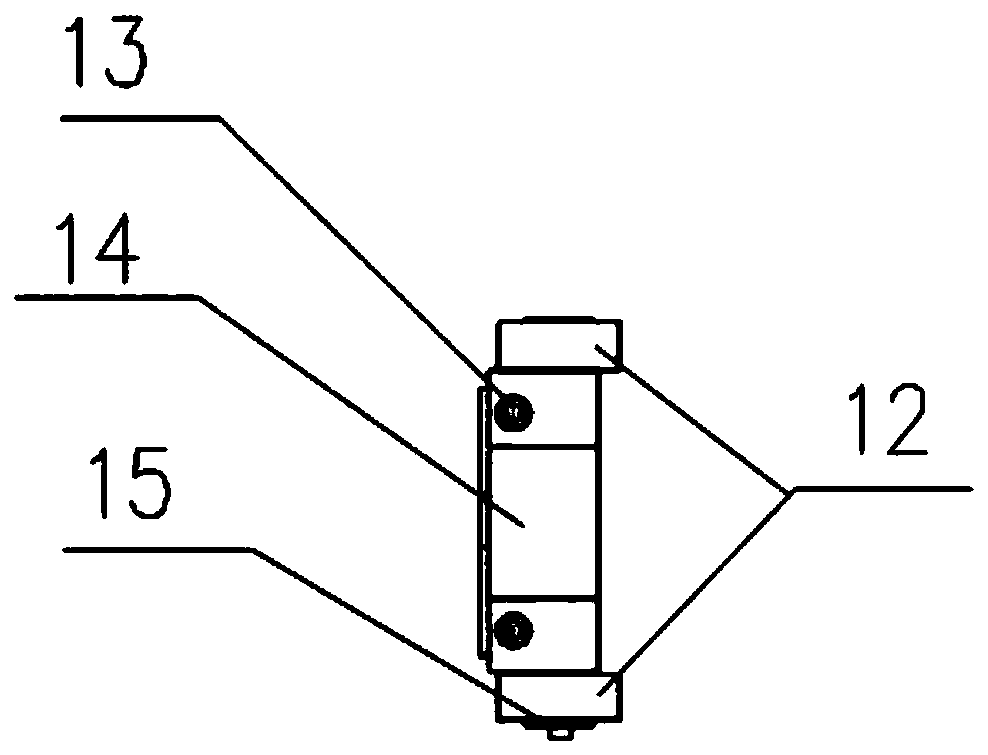

[0063] The frame outer track assembly include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com