Water sports boat and manufacturing method thereof

A technology for water sports and boats, which is applied in the field of boat manufacturing, can solve the problems of difficult mold opening and complicated manufacturing process, and achieve the effects of weight improvement, increase in output and reduction in defective rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

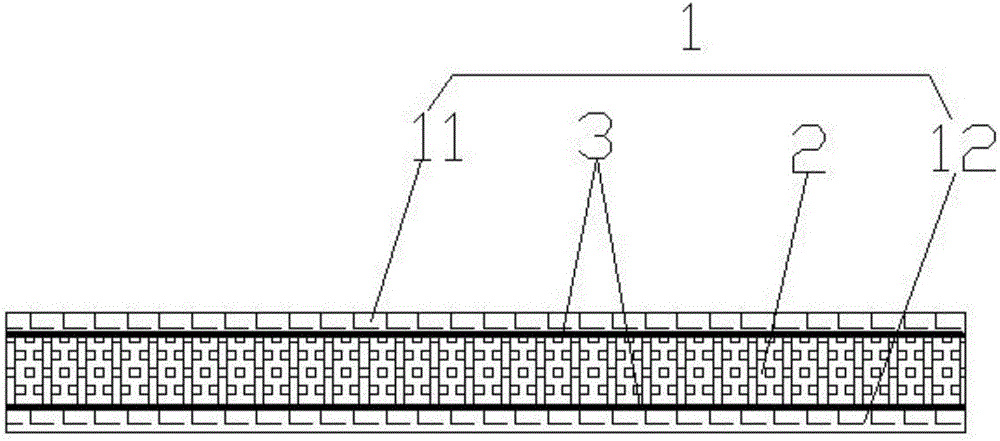

[0020] as attached figure 1 Shown is a water sports boat of the present invention, including a boat body 1, the boat body 1 is composed of an ABS material shell and an EPS foam layer 2; the ABS material shell has an upper template 11 and a lower template 12 After the surface of the EPS foam layer 2 is fully covered with glass fiber cloth, it is fixed between the upper template 11 and the lower template 12.

[0021] The EPS foam layer 2 is processed by CNC to form an EPS foam structure completely attached to the upper template and the lower template. After the EPS foam structure surface is covered with glass fiber cloth 3, it is fixed between the described upper template 11 and the lower template 12 by vacuum pressing after coating glue.

[0022] The above structural design not only reduces the weight of the boat, but also greatly improves ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com