Vacuum forming machine applied to airplane panel

A vacuum forming machine and panel technology, applied in lamination devices, control lamination, layered product processing, etc., can solve the problem of affecting the quality and yield of aircraft cabin panel wallpaper molding, the vacuum level can only be adjusted manually, and the operation is complicated, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0150] A method for using a vacuum forming machine applied to an aircraft panel, comprising the steps of:

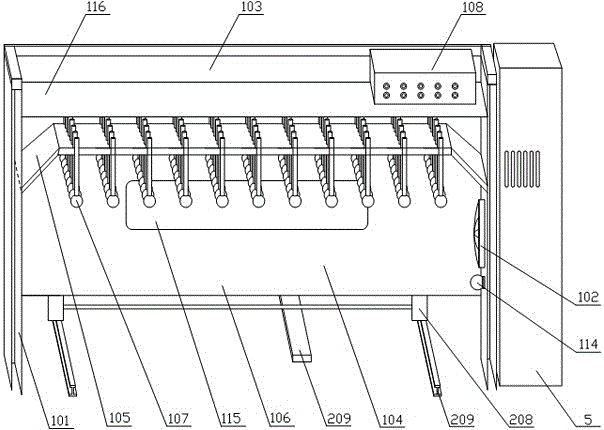

[0151] (1) Program the PLC controller 4 in advance according to the needs of the vacuum lamination process conditions;

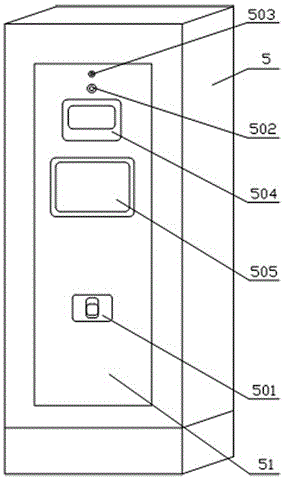

[0152] (2) Turn on the main power switch 501, the emergency stop button 502 is in the reset state, the paperless recorder 504 and the operation touch screen 505 light up and the display interface and touch screen operation interface appear, at this time the buzzer indicator light on the touch screen operation interface Displayed in red, that is, an alarm occurs, and the buzzer 503 buzzes, press the alarm to accept on the touch screen operation interface, and then press the alarm to reset to eliminate the alarm;

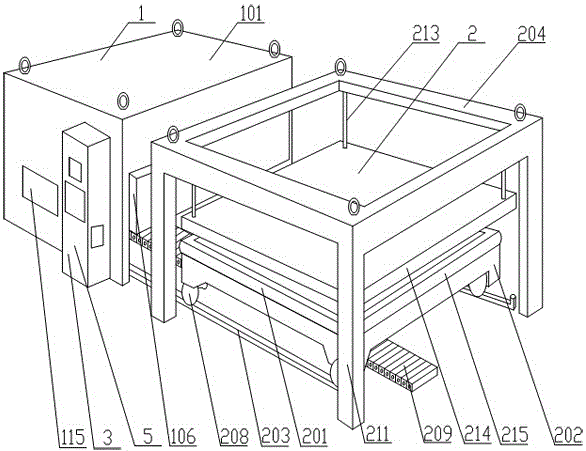

[0153] (3) Put the aircraft panel 10 to be laminated into the vacuum bed 201 installed on the transport vehicle 202, use the pressing mechanism 220 on the rectangular frame 216 to seal the vacuum bed 201, and then seal the vacuum bed 201 on th...

Embodiment 2

[0162] A method for using a vacuum forming machine applied to an aircraft panel, comprising the steps of:

[0163] (1) Program the PLC controller 4 in advance according to the needs of the vacuum lamination process conditions;

[0164] (2) Turn on the main power switch 501, the emergency stop button 502 is in the reset state, the paperless recorder 504 and the operation touch screen 505 light up and the display interface and touch screen operation interface appear, at this time the buzzer indicator light on the touch screen operation interface Displayed in red, that is, an alarm occurs, and the buzzer 503 buzzes, press the alarm to accept on the touch screen operation interface, and then press the alarm to reset to eliminate the alarm;

[0165] (3) Put the aircraft panel 10 to be laminated into the vacuum bed 201 installed on the transport vehicle 202, use the pressing mechanism 220 on the rectangular frame 216 to seal the vacuum bed 201, and then seal the vacuum bed 201 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com