Instant cold and hot forming method and forming equipment for multi-color products

A molding method, cold and hot technology, applied in the field of instant cold and hot molding methods and molding equipment for multi-color products, can solve the problems of easy retention of air, many defective products, low output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

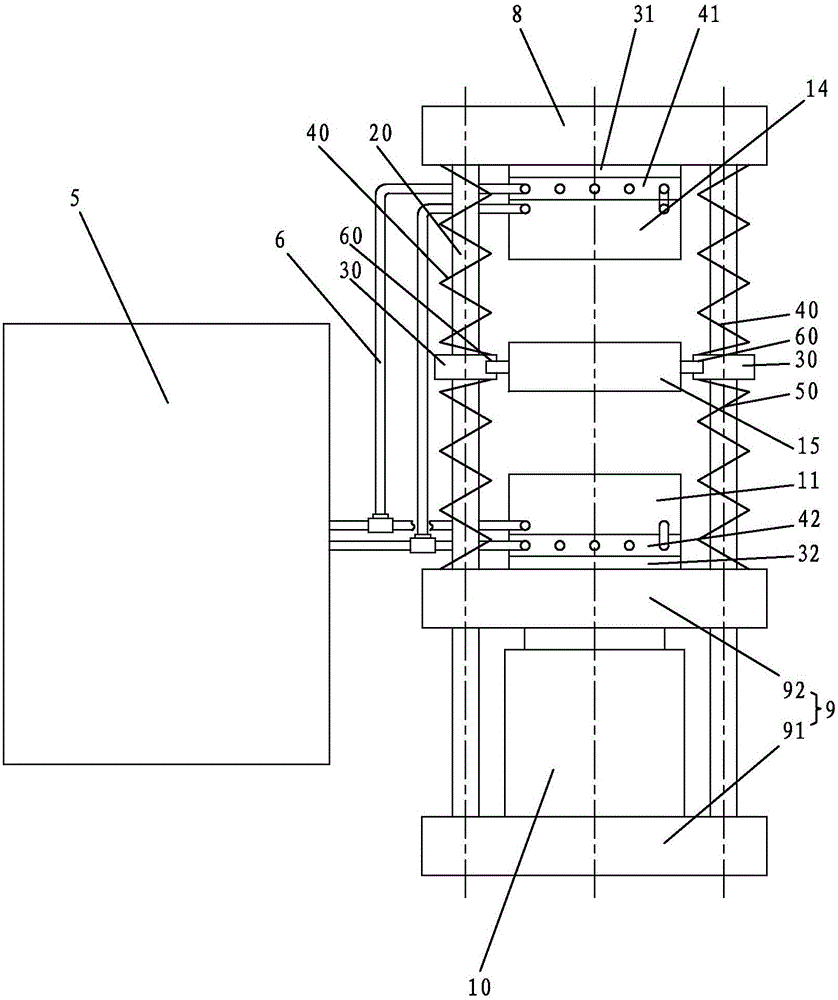

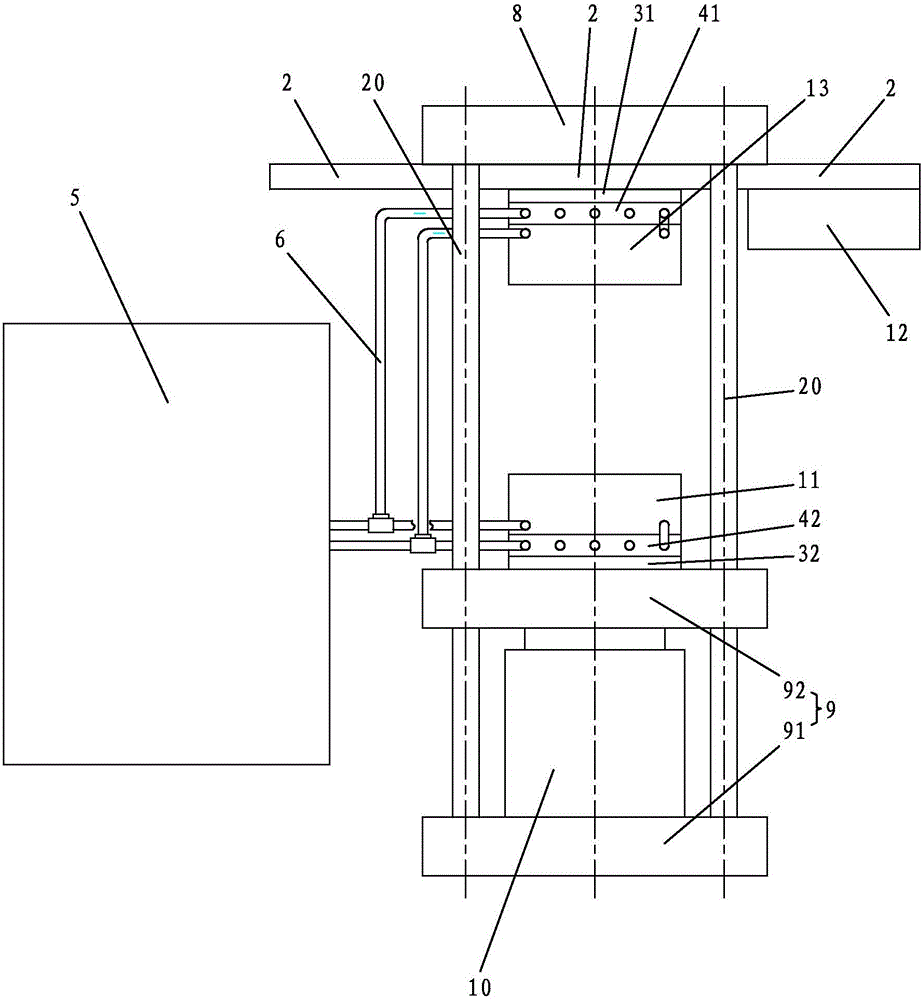

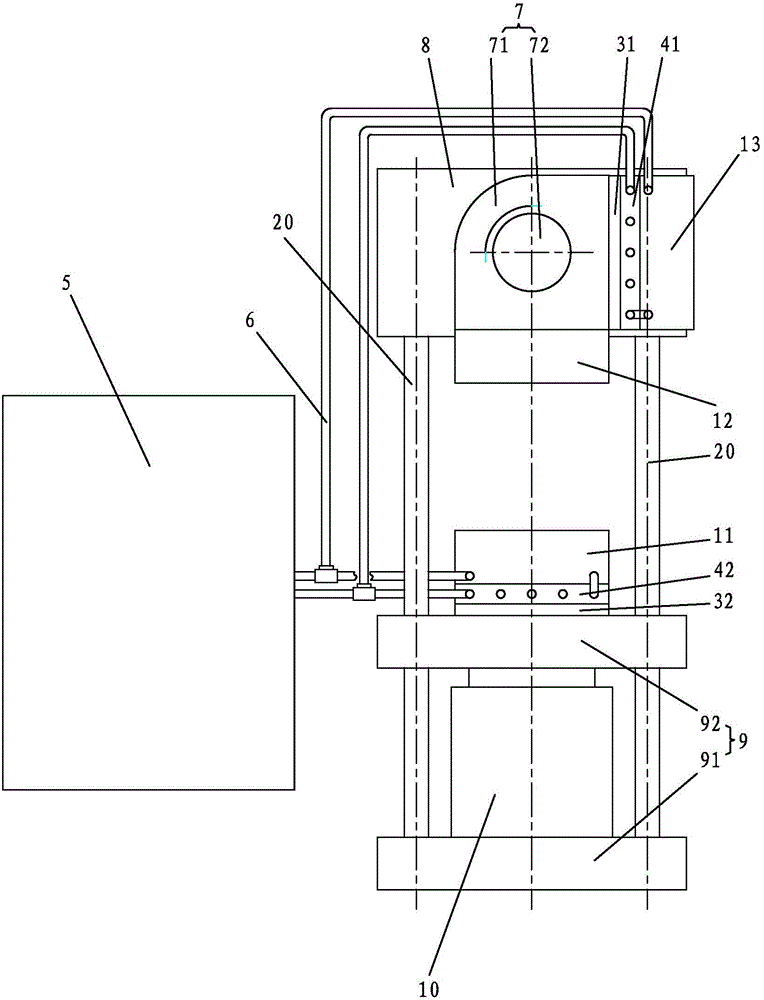

[0066] Instant hot and cold forming method of multi-color product of the present invention, as Figure 1-3 shown, including the following steps:

[0067](1) Ensure that the mold 1 is in a cold mold state (the cold mold state is a lower temperature state required for injection molding multi-color product blanks), and injection molding multi-color product blanks in the cold mold state;

[0068] (2) Do not take out the multi-color product blank, keep the multi-color product blank in the same mold and do not leave the mold cavity of mold 1, and then mold 1 for a certain period of time (this time can be designed according to actual requirements, such as in order to improve efficiency) It can be as short an instantaneous time as possible, such as 30-500 seconds, specifically can be 30, 40, 50, 60, 70, 80, 90, 100, 200, 300, 400 and 500 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com