Manufacturing method of pre-embedded fixing parts in skateboard

A manufacturing method and a technology for fixing parts, which are applied to household components, household appliances, and other household appliances, can solve problems such as complex processes, limiting the range of use of skateboards, and affecting the effect of skateboard movement, achieving simple processes, good processing effects, and solving problems. Insufficient fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

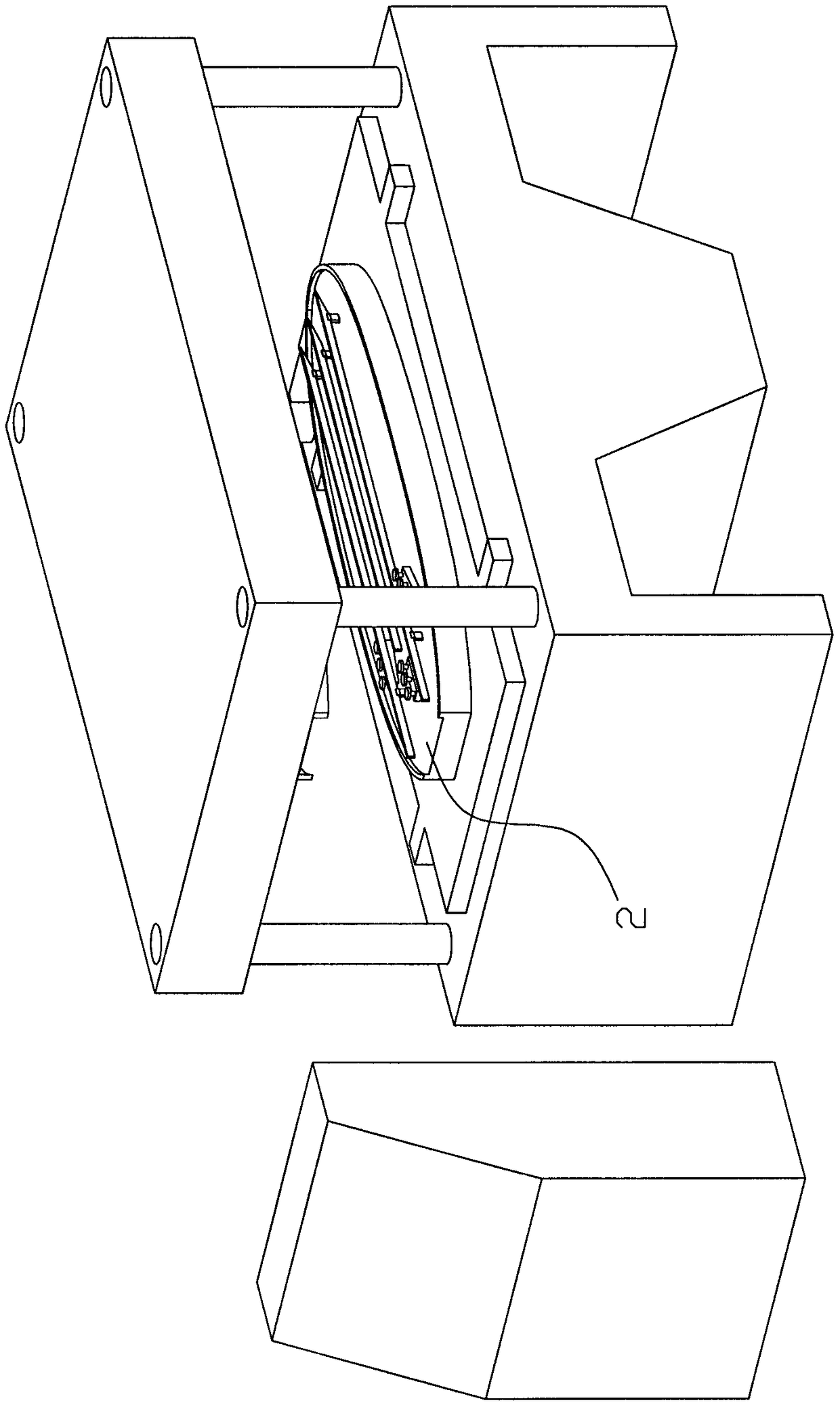

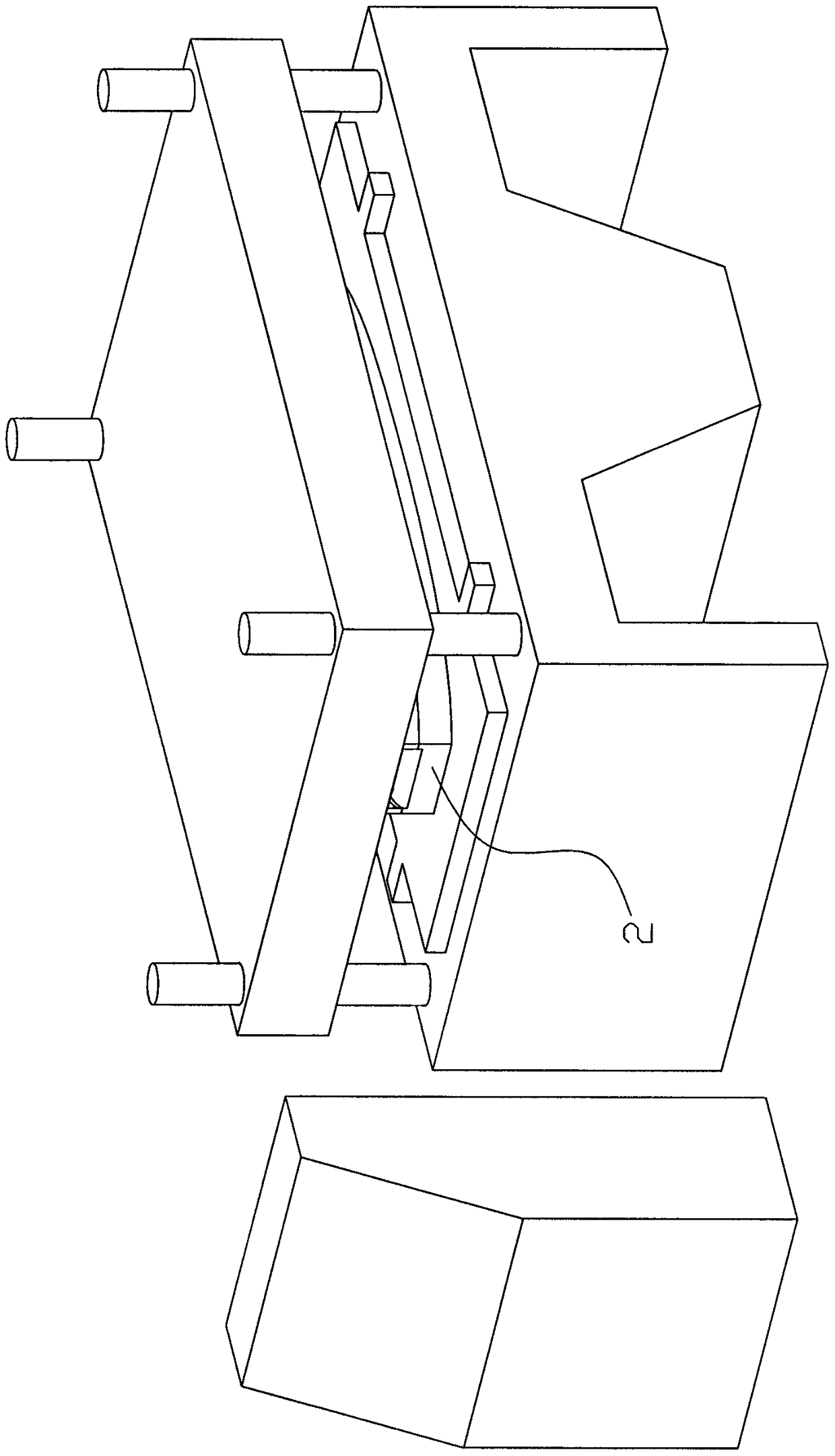

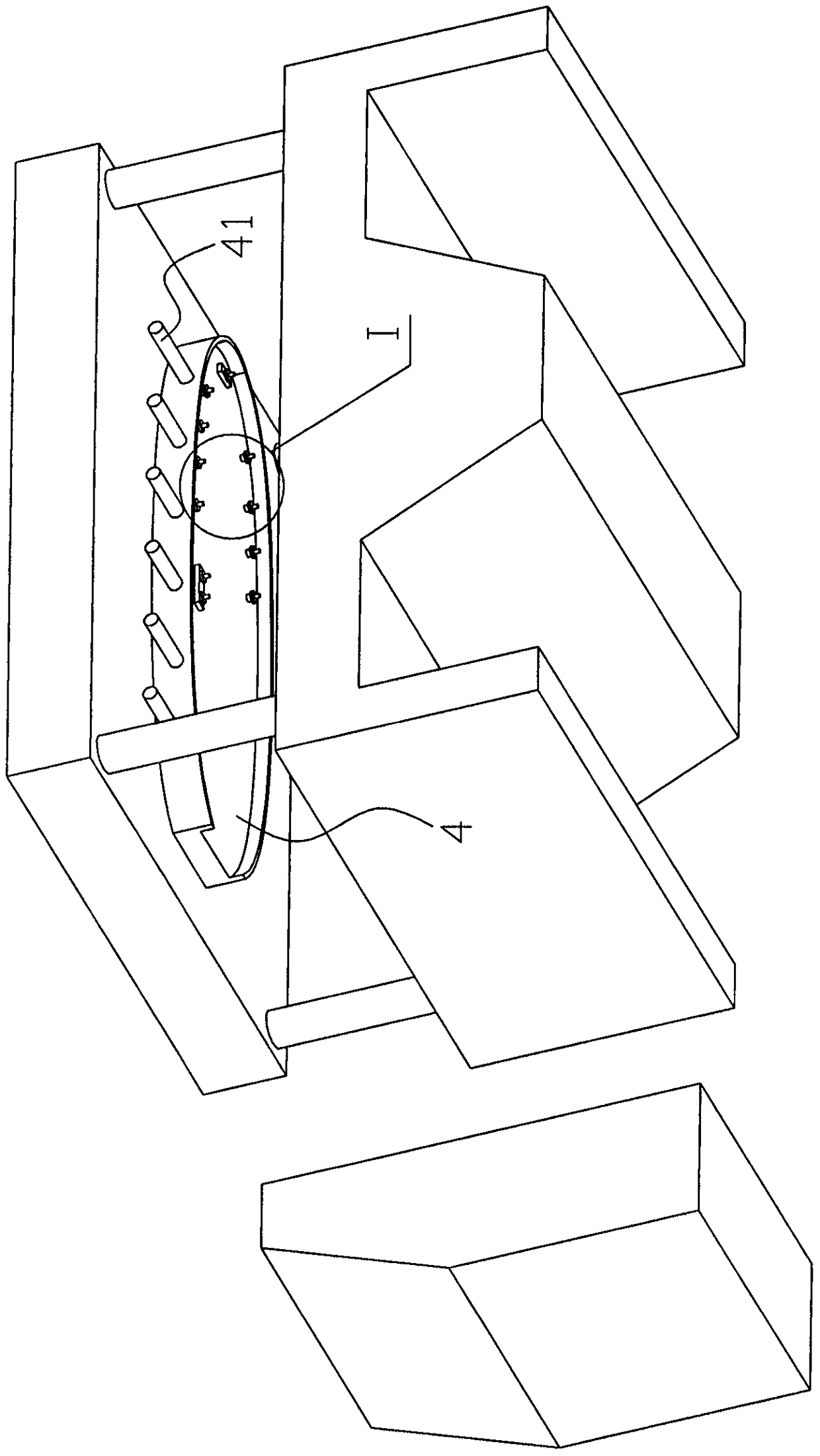

[0027] Such as Figure 1 to Figure 7 As shown, the manufacturing method of the pre-embedded fixing part in the skateboard of the present embodiment consists of the following steps;

[0028] 1. Fix the pre-embedded fixing part 1 connected with the corresponding slide plate connector to the corresponding positioning part 21 on the upper surface of the corresponding lower mold 2 in a detachable manner. After the pre-embedded fixing part 1 and the corresponding positioning part 21 are fixed, the The remaining pre-embedded fixing part 1 is detachably fixed on the corresponding positioning convex part 42 corresponding to the lower surface of the upper mold 4;

[0029] 2. Place the reinforcing ribs 3 that increase the strength of the slide plate in the middle of the upper surface of the lower mold 2 in parallel at intervals, and the embedded fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com