Fixture for chamfering machine

A chamfering machine and fixture technology, which is used in manufacturing tools, grinding machine parts, machine tools suitable for grinding workpiece edges, etc. The effect of low manual skill requirements, prevention of glass splashing, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

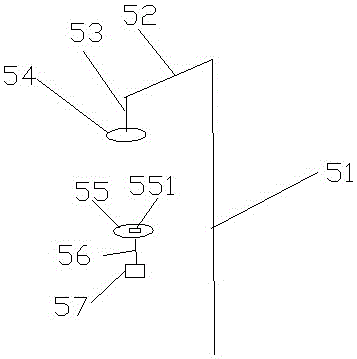

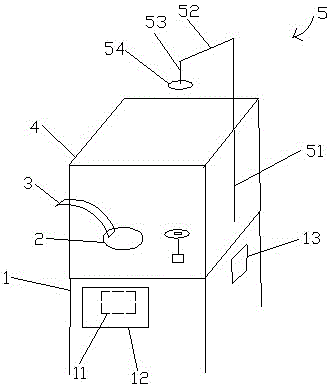

[0018] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments. Such as figure 1 with figure 2 as shown,

[0019] A fixture for a chamfering machine, including a frame 1, a first motor 11, an operation panel 12, a second motor 13, a grinding disc 2, a cooling water pipe 3, a protective cover 4, a glass clamping device 5, and a rotating lifting rod 51 , crossbar 52, suspension rod 53, vacuum suction cup 54, fixed disc 55, pressure sensor 551, rotating shaft 56 and the third motor 57 and other main technical features.

[0020] A fixture for a chamfering machine, that is, a glass clamping device 5, which includes a rotating lifting rod, a cross rod, a suspension rod, a vacuum suction cup, a fixed disk, a rotating shaft and a third motor.

[0021] The bottom of the rotating elevating rod is fixedly arranged on the frame, and the height of the rotating elevating rod can be lifted and rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com