Novel stir friction welding tool for non-thinned post-welded material surface

A friction stir and post-weld technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problem of no weld thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

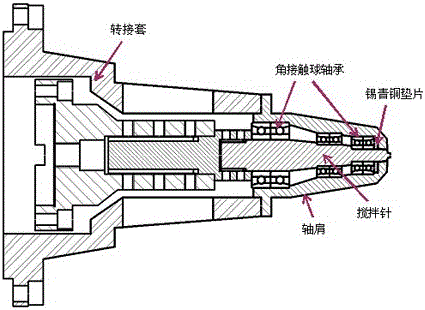

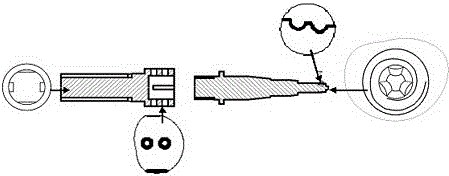

[0012] refer to figure 1 , The assembly of the welding tool in the present invention includes six parts: an adapter sleeve, a knife handle, a stirring tool, a shaft shoulder, a bearing and a copper gasket. First, assemble the angular contact ball bearings and the mixing tool. The bearings are installed in a back-to-back arrangement. Trial assembly with the shaft shoulder is performed to adjust the bearing clearance. Match the assembly and adjust to the attached figure 2 The center line of the inclined surface of the middle stirring pin is flush with the end surface of the shaft shoulder; install the tool handle on the main machine head of the equipment, rotate the main shaft, measure the coaxiality of the tool handle installation, and stop the main shaft under the premise that the coaxiality is less than 0.04mm. Assemble the split stirring t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com