Crossbeam fixing type all-hydraulic driving digital-control friction stitch welding machine with large operating space

An operation space, friction stitch welding technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of limited welding range in one clamping, small manual operation space for divers, and poor strength of clamping and positioning mechanism, etc. Excellent dynamic and static performance, large working range, reliable clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

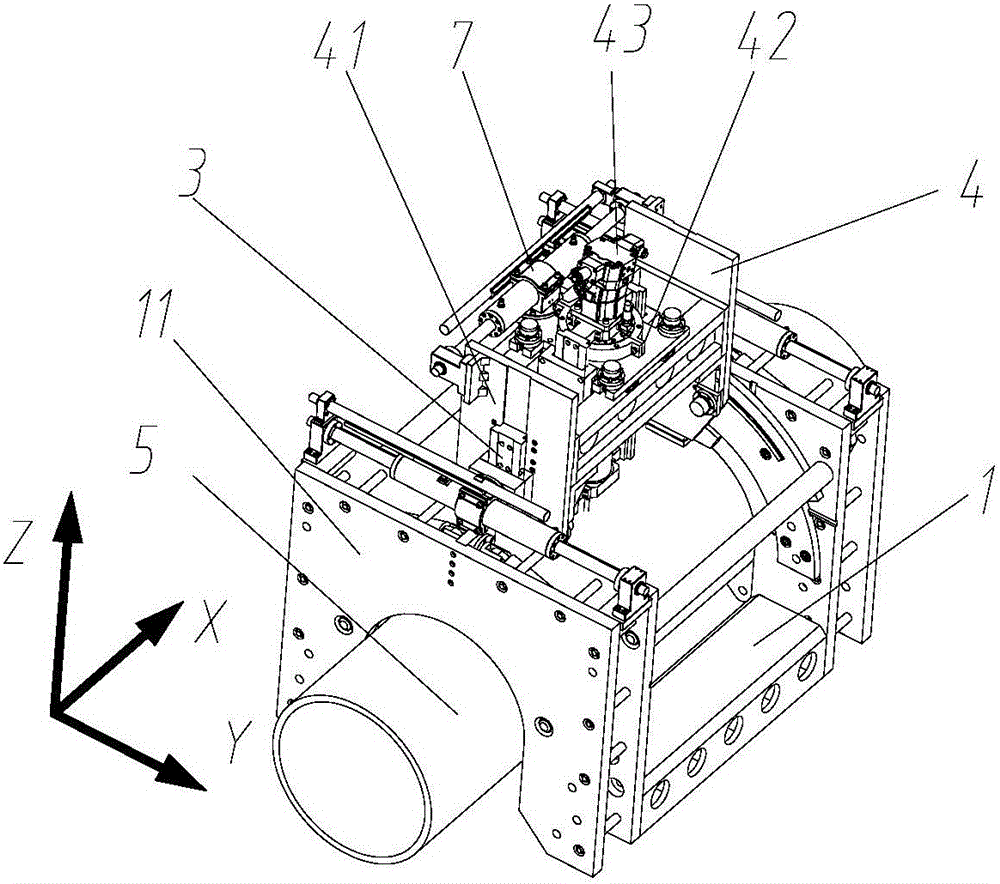

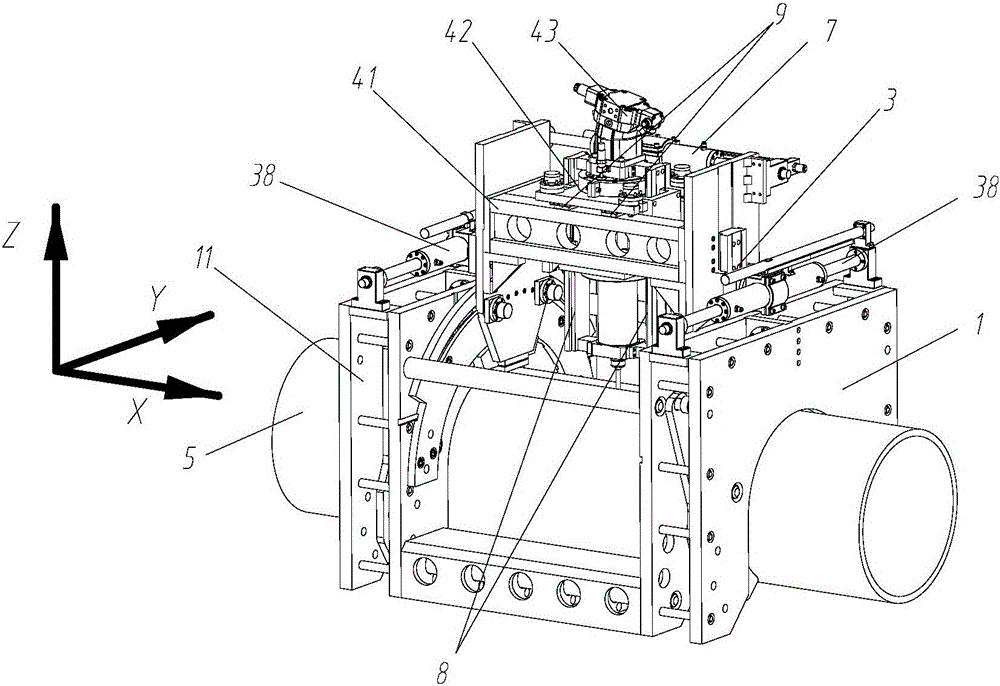

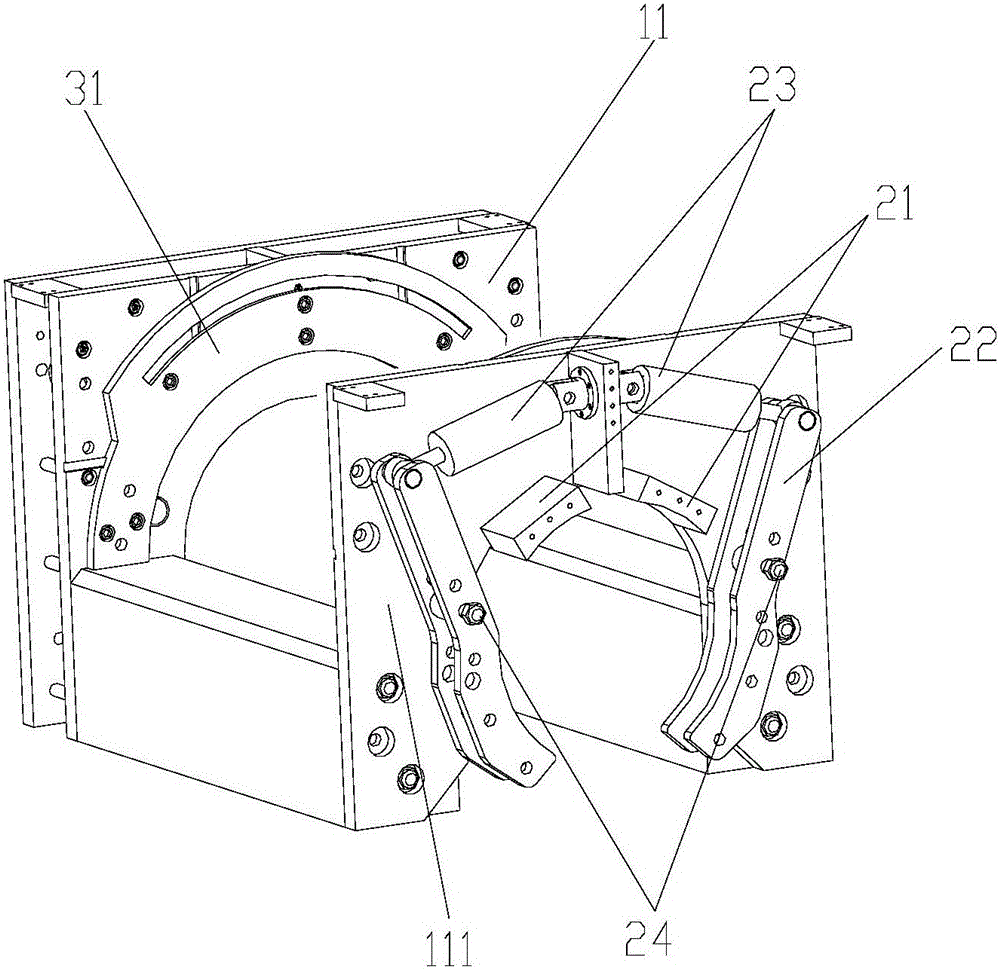

[0032] see Figure 1 to Figure 10 , a fully hydraulically driven digitally controlled friction stitch welding machine with a large operating space and a fixed beam, including a frame 1 and a clamping mechanism 2 connected thereto, a circumferential moving mechanism 3 and a welding device 4 .

[0033]The welding device 4 includes a welding bracket 41, a main shaft mounting frame 42 and a main shaft 43; the welding bracket 41 includes two symmetrical side plates II 411, and the two side plates II 411 pass through two beams arranged symmetrically front and rear 412 are fixed together, and the two beams 412 and the two left and right side plates II411 form a frame structure; the main shaft installation frame 42 is slidably connected in the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com