Organic matter processing equipment high in discharging efficiency

一种处理设备、有机质的技术,应用在机械设备、谷物处理、发动机元件等方向,能够解决很难增加有效截面积、无法达到爆碎效果、加压泄压装置泄压速度难提高等问题,达到提高受力情况和实现效果、结构紧凑、体积小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The organic matter processing equipment of the present invention will be described in detail below in conjunction with the accompanying drawings.

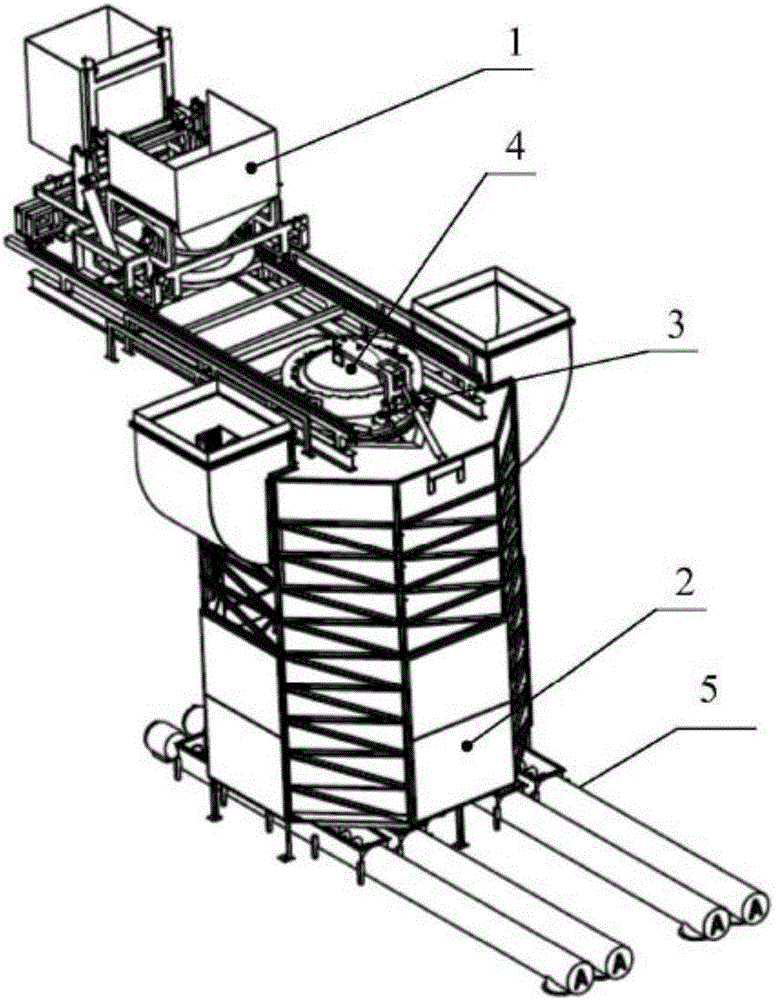

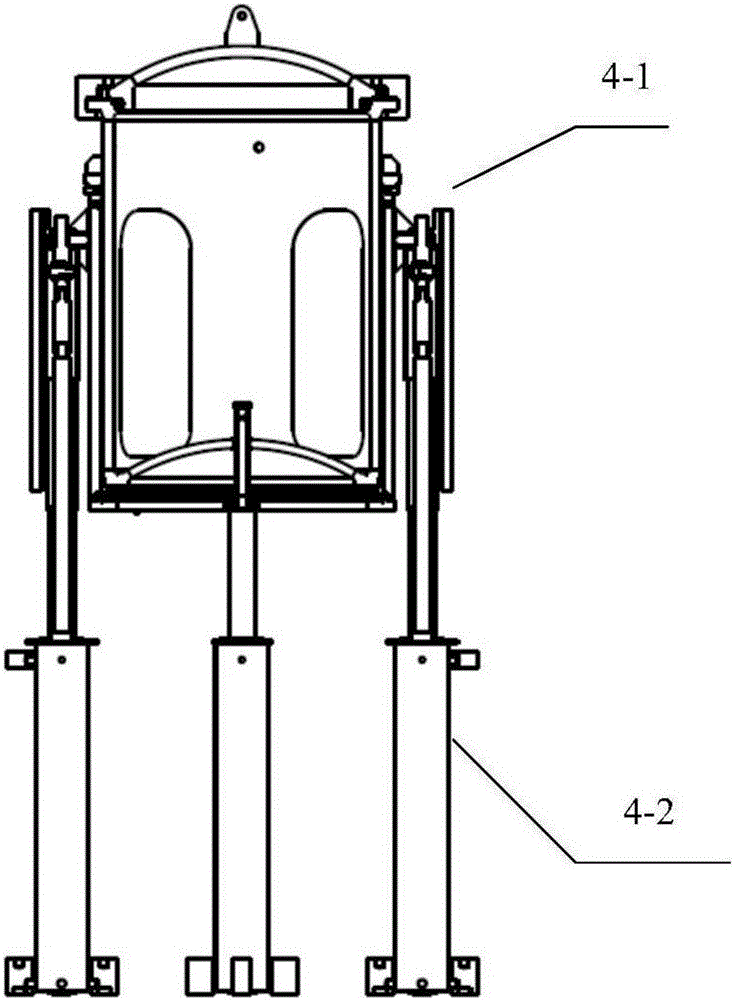

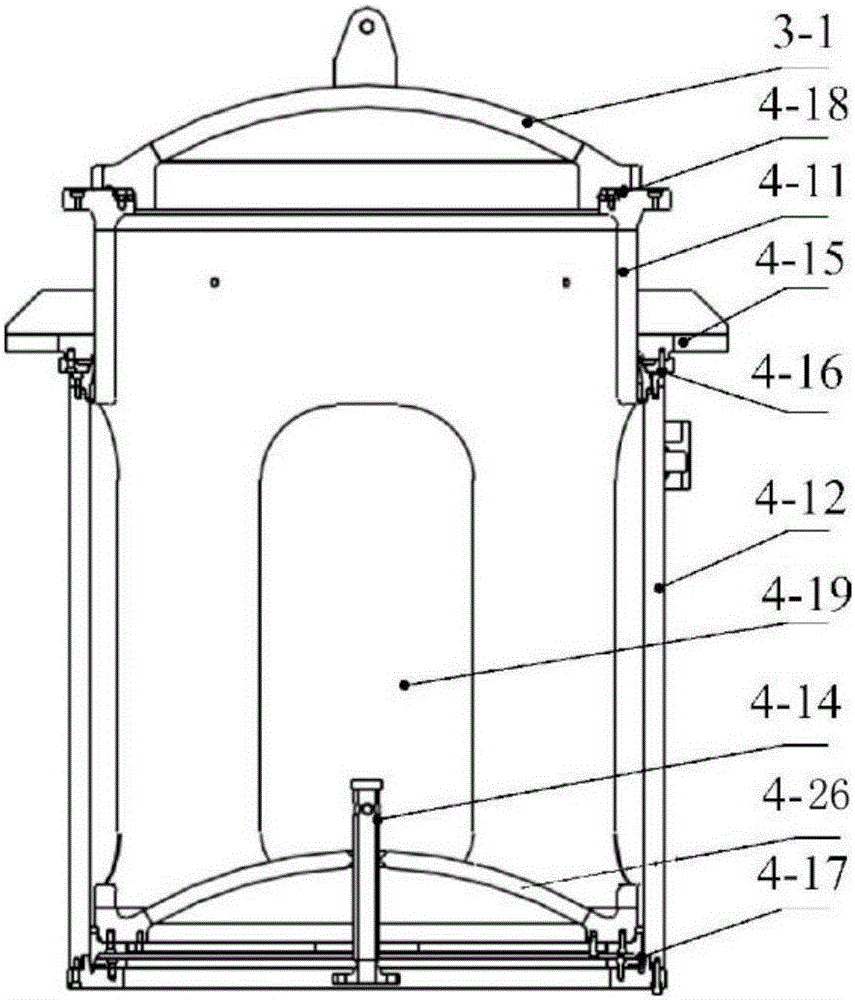

[0050] Such as figure 1 Shown is a schematic structural diagram of the large-diameter organic matter processing equipment. It can be seen from the figure that the large-diameter organic matter processing equipment specifically includes a feeding device 1, a separator 2, a cover opening mechanism 3, a pressurization and pressure relief device 4, and a discharge device 5. The pressure relief device 4 is installed inside the separator 2, the cap opening mechanism 3 and the feeding device 1 are installed on the upper part of the pressure relief device 4, that is, the top of the separator 2, and the discharge device 5 is located below the separator 2 , wherein the feeding device 1 injects the material into the inside of the pressure relief device 4 through the cap opening device 3, the pressure relief device 4 heats and pressuriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com