Preparation method for electro-geochemical adsorption material for uranium exploration

A technology of geoelectrochemistry and adsorption materials, which is applied in the field of uranium resource exploration, can solve the problems of low extraction efficiency of uranium elements, achieve the effects of highlighting the indication function, improving the adsorption capacity, and reducing the background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

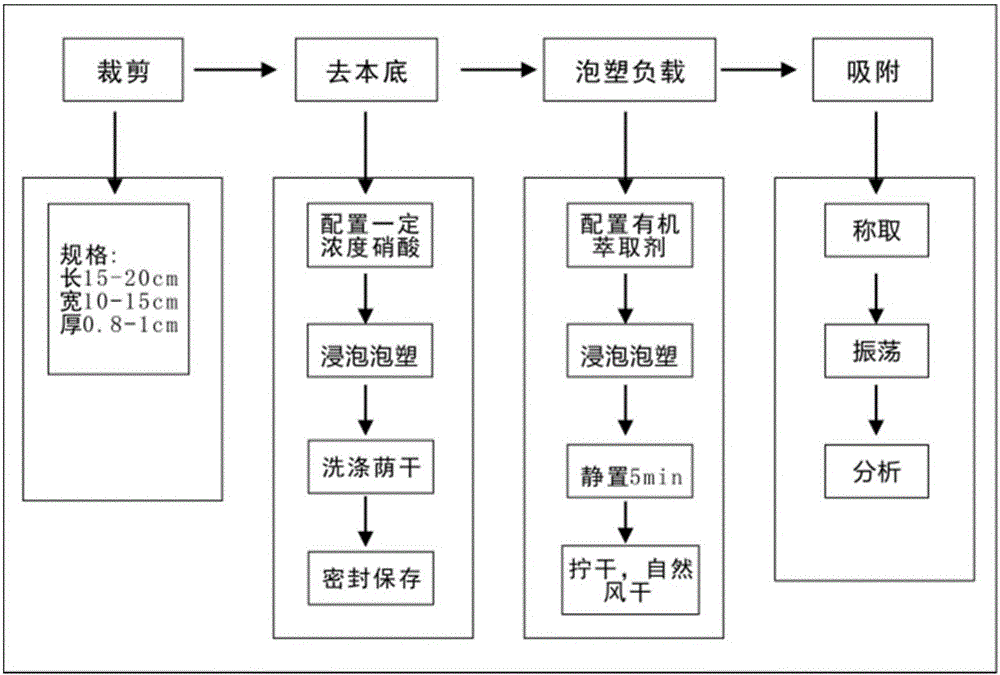

[0025] This embodiment provides a method for preparing a geoelectrochemical adsorption material in uranium ore exploration, the steps are as follows:

[0026] 1), take polyurethane foam plastics, cut it and grow into polyurethane foam plastics with a width of 10 cm and a thickness of 0.8 cm.

[0027] 2), get 1) gained polyurethane foam and place in nitric acid aqueous solution and soak 48h, obtain the polyurethane foam after soaking; The volume fraction of nitric acid in the described nitric acid aqueous solution is 15%, and described nitric acid aqueous solution is made of high-purity nitric acid and deionized Water configuration; the volume of the polyurethane foam is 1 / 2 of the volume of nitric acid aqueous solution for soaking.

[0028] 3) Use deionized water to wash the soaked polyurethane foam obtained in 2) for 3 times, then twist and dehydrate, and then place it in a ventilated place to dry in the shade to obtain the background-removed polyurethane foam.

Embodiment 2

[0030] This embodiment provides a method for preparing a geoelectrochemical adsorption material in uranium ore exploration, the steps are as follows:

[0031] 1), take the polyurethane foam plastics, and cut it into polyurethane foam plastics with a width of 20 cm, a width of 15 cm, and a thickness of 1 cm.

[0032] 2), get 1) gained polyurethane foam and place in nitric acid aqueous solution and soak 24h, obtain the polyurethane foam after soaking, polyurethane foam is submerged below the liquid level of nitric acid aqueous solution completely in the soaking process; In described nitric acid aqueous solution, the volume fraction of nitric acid is 25%, the nitric acid aqueous solution is configured by high-purity nitric acid and deionized water; the volume of the polyurethane foam is 1 / 3 of the volume of the nitric acid aqueous solution for soaking.

[0033] 3) Use deionized water to wash the soaked polyurethane foam obtained in 2) 5 times, then twist and dehydrate, and then p...

Embodiment 3

[0035] This embodiment provides a method for preparing a geoelectrochemical adsorption material in uranium ore exploration, the steps are as follows:

[0036] 1), take polyurethane foam plastics, cut it and grow into polyurethane foam plastics with 18cm in width, 13cm in width and 0.9cm in thickness.

[0037] 2), get 1) gained polyurethane foam and place in nitric acid aqueous solution and soak 36h, obtain the polyurethane foam after soaking, in soaking process, polyurethane foam is submerged below the nitric acid aqueous solution liquid level completely; In the described nitric acid aqueous solution, the volume fraction of nitric acid is 20%, the nitric acid aqueous solution is configured by high-purity nitric acid and deionized water; the volume of the polyurethane foam is 1 / 4 of the volume of the nitric acid aqueous solution for soaking.

[0038] 3) Use deionized water to wash the soaked polyurethane foam obtained in 2) for 4 times, then twist and dehydrate, and then place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com