Moringa oleifera yogurt and preparation method thereof

A technology of yogurt and Moringa, applied in the directions of milk preparations, bacteria and dairy products used in food preparation, can solve the problems of lack of development of Moringa fermented food, many kinds of additives, and insufficiently delicate taste, and achieves good elasticity, The effect of good texture and high taste satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

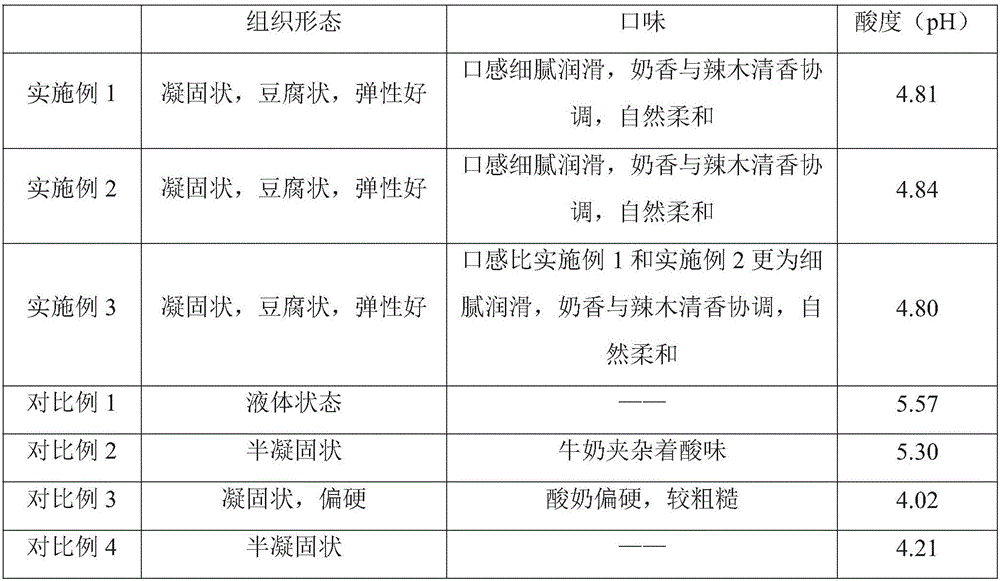

Examples

Embodiment 1

[0026] The preparation of embodiment 1 Moringa yoghurt

[0027] Embodiment 1 of the present invention Moringa yoghurt, its preparation raw material comprises the following ingredients: milk, according to the solid-to-liquid ratio with milk, Moringa leaf superfine powder 15.5g / L, white granulated sugar 88g / L, β-cyclodextrin 130g / L And yogurt starter 1.05g / L.

[0028] Preparation:

[0029] S1: After removing impurities and washing the leaves of Moringa oleifera, steam them at 95°C for 3 minutes, dry them with hot air at 50°C for 4 hours, pulverize them, and pass through a 60-mesh sieve to obtain coarse powder of Moringa leaves, which is ultrafinely pulverized. Pass through a 500-mesh sieve to obtain Moringa leaf superfine powder;

[0030] S2: Take β-cyclodextrin, add water to make a saturated solution at a temperature of 60°C, add superfine powder of Moringa oleifera leaves, mix and ultrasonicate for 2 hours under the condition of ultrasonic power of 250W, vacuum dry, pulveriz...

Embodiment 2

[0034] The preparation of embodiment 2 Moringa yoghurt

[0035] Embodiment 2 of the present invention Moringa yoghurt, its preparation raw material comprises following composition: milk, by the solid-to-liquid ratio with milk, Moringa leaf superfine powder 16g / L, white granulated sugar 93g / L, beta-cyclodextrin 133g / L and Yogurt starter 0.97g / L.

[0036] Preparation:

[0037] S1: After removing impurities and washing the leaves of Moringa oleifera, steam them at 100°C for 2 minutes, dry them with hot air at 50°C for 4 hours, pulverize them, and pass through a 60-mesh sieve to obtain coarse powder of Moringa oleifera leaves, which is ultrafinely pulverized. Cross 800 mesh sieves to obtain superfine powder of Moringa oleifera leaves;

[0038] S2: Take β-cyclodextrin, add water to make a saturated solution at a temperature of 50°C, add superfine powder of Moringa oleifera leaves, mix and ultrasonicate for 1 hour under the condition of ultrasonic power of 300W, vacuum dry, pulver...

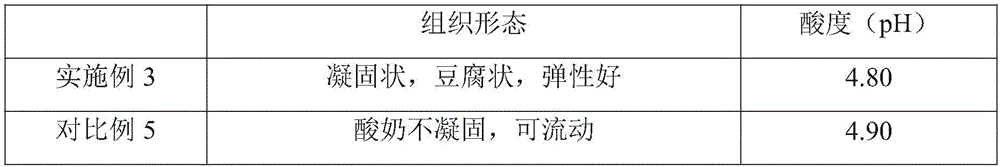

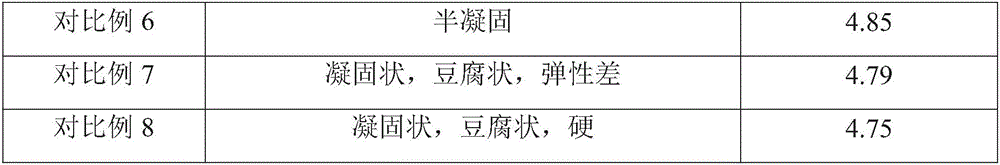

Embodiment 3

[0042] The preparation of embodiment 3 Moringa yoghurt

[0043] Embodiment 2 of the present invention Moringa yoghurt, its preparation raw material comprises following composition: milk, by the solid-to-liquid ratio with milk, Moringa leaf superfine powder 16g / L, white granulated sugar 90g / L, β-cyclodextrin 130g / L and Yogurt starter 1.0g / L.

[0044] Preparation:

[0045] S1: Take Moringa oleifera leaves to remove impurities and wash them, steam them at 100°C for 3 minutes, dry them with hot air at 50°C for 5 hours, pulverize them, and pass through a 60-mesh sieve to obtain Moringa oleifera leaf powder, which is ultrafinely pulverized. Pass through a 800-mesh sieve to obtain superfine powder of Moringa oleifera leaves;

[0046]S2: Take β-cyclodextrin, add water to make a saturated solution at a temperature of 60°C, add superfine powder of Moringa oleifera leaves, mix and ultrasonicate for 2 hours under the condition of ultrasonic power of 250W, vacuum dry, pulverize, pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com