Lithium-ion battery electrolyte, lithium-ion battery and electronic instrument

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of insufficiency and low energy density, and achieve the effect of improving service life, large capacity retention rate, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] Preparation of polymer lithium-ion batteries:

[0121] The negative electrode is made of artificial graphite with a compacted density of 1.70g / cm 3 ;

[0122] The electrolyte solvent is: 30% EC (ethylene carbonate), 30% DEC (diethyl carbonate), 20% PP (propyl propionate) and 20% PC (propylene carbonate) mixed solvent;

[0123] Additives are: 0.5% DTD (ethylene sulfate), 5% FEC (fluoroethylene carbonate), 0.5% VC (vinylene carbonate), 2% SN (succinonitrile), 2% ADN (adiponitrile ), 0.5% ethylene glycol (dipropionitrile) ether, 3% PS (1,3-propane sultone) and 4% fluorobenzene mixed;

[0124] Electrolyte lithium salt: 1.10M LiPF 6 ;

[0125] Copper current collector primer material is: a mixed coating of carbon black, binder SBR, and dispersant CMC, with a coating thickness of 0.5 μm;

[0126] The positive electrode material is: Hunan Shanshan Lithium Cobalt Oxide LC9000E.

[0127] The diaphragm is Korean SK, PE 7μm.

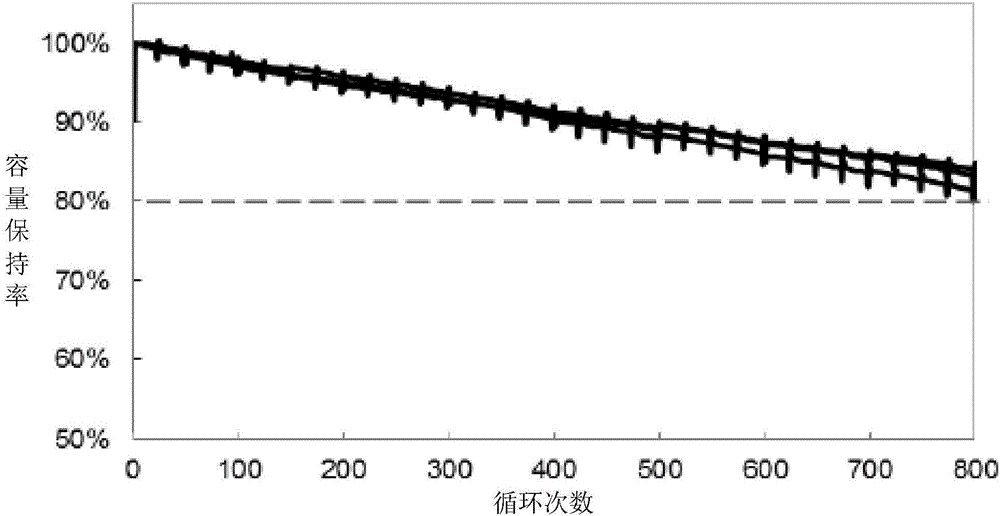

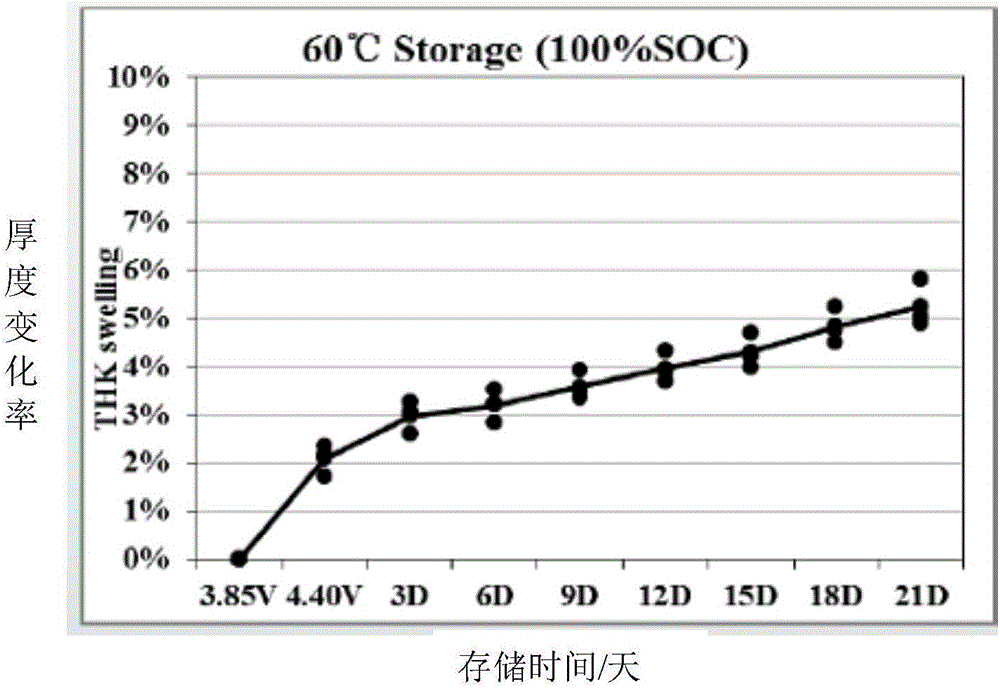

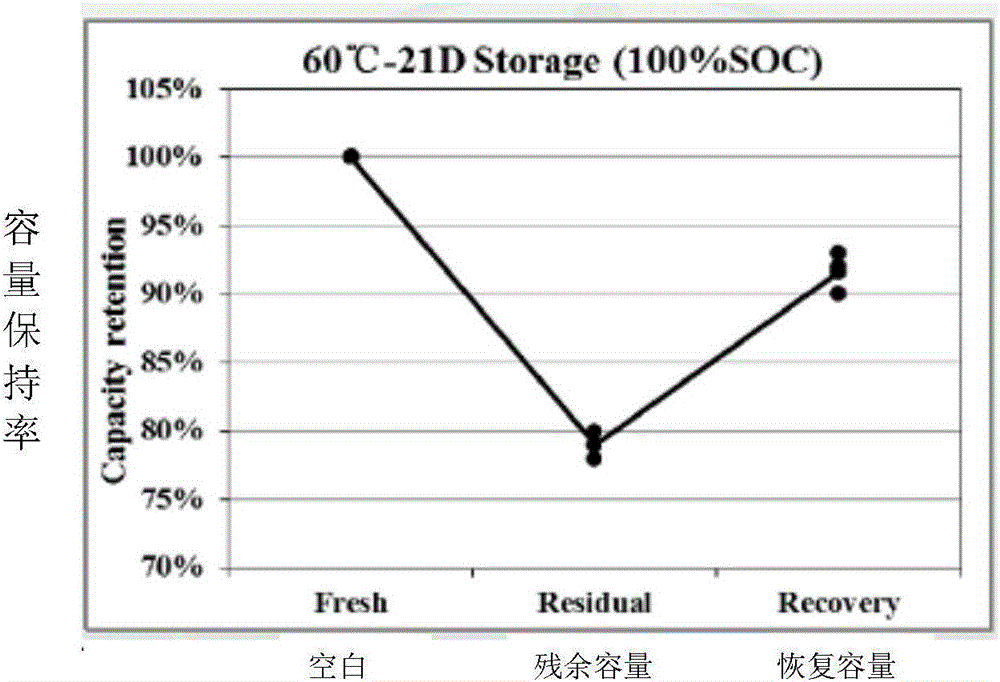

[0128] The prepared polymer lithium-ion battery...

Embodiment 2

[0138] Preparation of polymer lithium-ion batteries:

[0139] The negative electrode is made of artificial graphite with a compacted density of 1.85g / cm 3 ;

[0140] The electrolyte solvent is: 30% EC (ethylene carbonate), 20% DEC (diethyl carbonate), 20% PP (propyl propionate) and 30% PC (propylene carbonate) mixed solvent;

[0141] Additives are: 0.1% DTD (ethylene sulfate), 6% FEC (fluoroethylene carbonate), 0.1% VC (vinylene carbonate), 3% SN (succinonitrile), 3% ADN (adiponitrile ), 0.5% ethylene glycol (dipropionitrile) ether, 4% PS (1,3-propane sultone) and 5% fluorobenzene mixed;

[0142] The electrolyte lithium salt is: 1.30M LiPF 6 ;

[0143] Copper current collector primer material is: a mixed coating of carbon black, binder SBR, and dispersant CMC, with a coating thickness of 0.5 μm;

[0144] The positive electrode material is: Hunan Shanshan Lithium Cobalt Oxide LC9000E.

[0145] The diaphragm is Korean SK, PE 7μm.

[0146] The electrical properties of the ...

Embodiment 3

[0151] Preparation of polymer lithium-ion batteries:

[0152] The negative electrode is made of artificial graphite with a compacted density of 1.85g / cm 3 ;

[0153] The electrolyte solvent is: 20% EC (ethylene carbonate), 30% DEC (diethyl carbonate), 30% PP (propyl propionate) and 20% PC (propylene carbonate) mixed solvent;

[0154] The additives are: 1% DTD (ethylene sulfate), 5% FEC (fluoroethylene carbonate), 1% VC (vinylene carbonate), 2% ADN (adiponitrile), 2% ethylene glycol (bis Propionitrile) ether, 3% PS (1,3-propane sultone) and 3% fluorobenzene mixed;

[0155] Electrolyte lithium salt: 1.30MLiPF 6 ;

[0156] Copper current collector primer material is: a mixed coating of carbon black, binder SBR, and dispersant CMC, with a coating thickness of 0.5 μm;

[0157] The positive electrode material is: Hunan Shanshan Lithium Cobalt Oxide LC9000E.

[0158] The diaphragm is Korean SK, PE 7μm.

[0159] The electrical properties of the prepared polymer lithium-ion batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com