Thickness measuring device and its method for steel material in red hot state

A thickness measurement and state technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of high rejection rate, inability to dynamically measure, linear distortion of laser sensors, etc., to facilitate maintenance and installation, automation of the measurement process, and reduction of The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

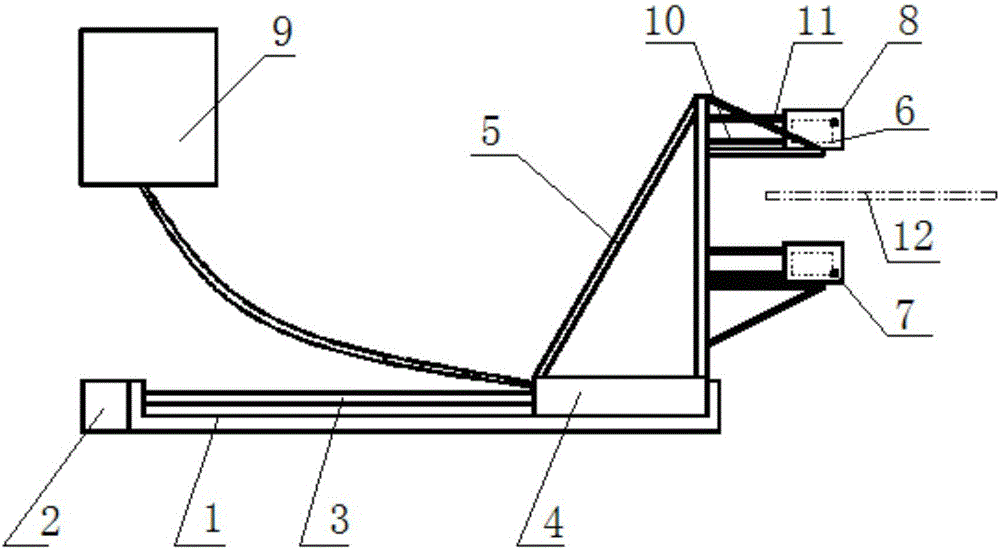

[0037] A guide rail 1 is installed on the foundation, and the stepper motor 2 is connected with the guide rail screw 3, which can drive the slider 4 to move laterally on the guide rail 1; the sensor bracket 5 is connected with the slider 4, and two incubators 8 are fixed on the sensor bracket 5 Upper, upper and lower symmetrical arrangements; water inlet pipe 10 and outlet pipe 11 are connected to incubator 8 to realize water circulation and cooling; laser displacement sensor 6 and temperature sensor 7 that can measure high-temperature objects are installed in the incubator; analyzer 9 controls the connection of power supply and The stepper motor 2 moves, and displays the measurement data and comparison results, and sends instructions in time to adjust the steel plate production line.

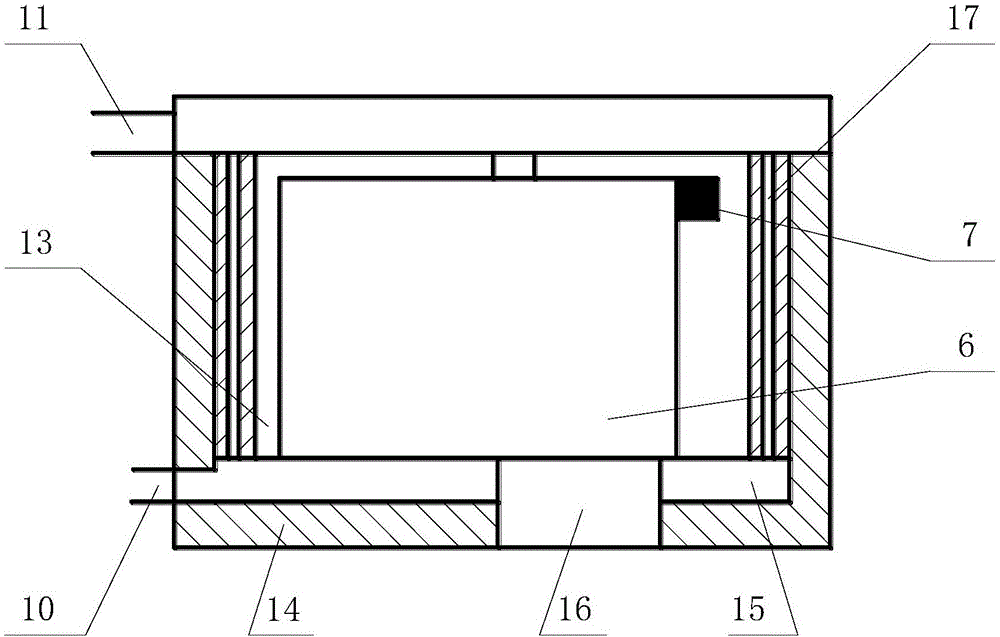

[0038] Such as figure 2 As shown, the incubator 8 includes an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com