Valve set for hydraulic coupling

A technology for hydraulic couplings and valve groups, applied in valve details, valve devices, chemical instruments and methods, etc., can solve the problems that the valve body cannot be closed, the control equipment is damaged, and the rejection rate is high, so as to improve safety and stability. , Easy to remove and clean, reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

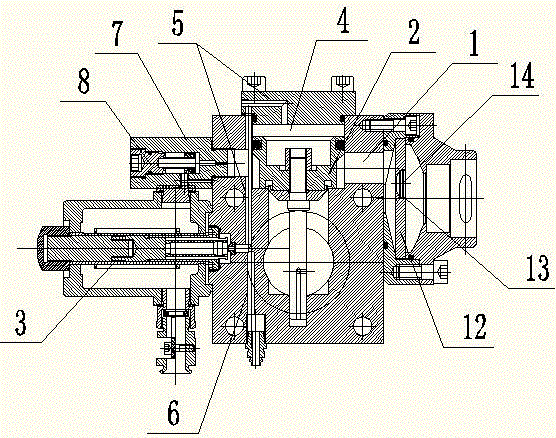

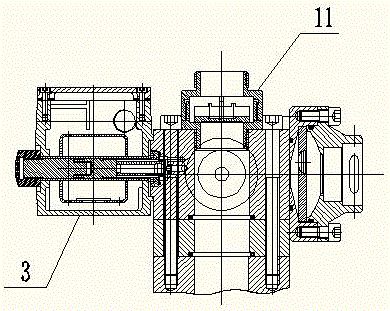

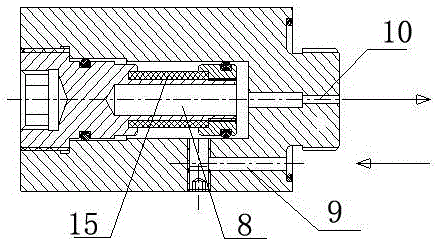

[0018] As shown in the accompanying drawing, a valve group for a hydraulic coupling includes a valve body, the valve body is provided with a liquid inlet 1, a liquid outlet, a valve stem piston 2, and a solenoid valve 3, and the valve stem piston 2 is used for on-off inlet and outlet. The waterway connected to the liquid port and the liquid outlet, the head of the valve stem piston is the backwater chamber 4, the backwater chamber 4 is connected to the return waterway 5, and the backwater way 5 controls the connection between the backwater way 5 and the signal waterway 6 through a solenoid valve, and the backwater way 5 An external filter 7 is fixedly connected with the valve body, and the external filter 7 is connected in series with the return water channel 5, and becomes a section of the filter water channel of the return channel. The external filter 7 includes an outer shell and a filter element 8, and the shell is provided with Waterway Ⅱ9, waterway Ⅲ10, one end of waterwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com