Gas plug valve

A technology for gas cock valves and valve stems, which is applied to cocks including cut-off devices, valve details, valve devices, etc. It can solve the problems of large gas volume, explosive sound, difficult multi-level flow control, etc., and achieve the goal of reducing gas output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

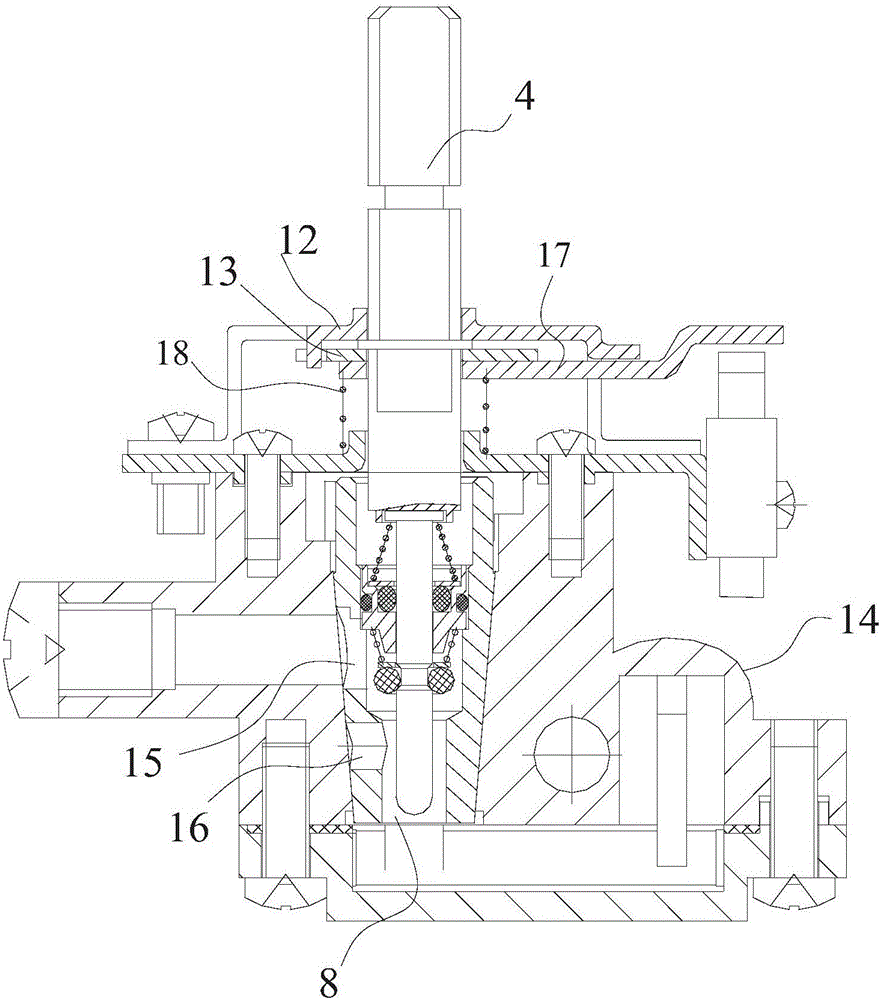

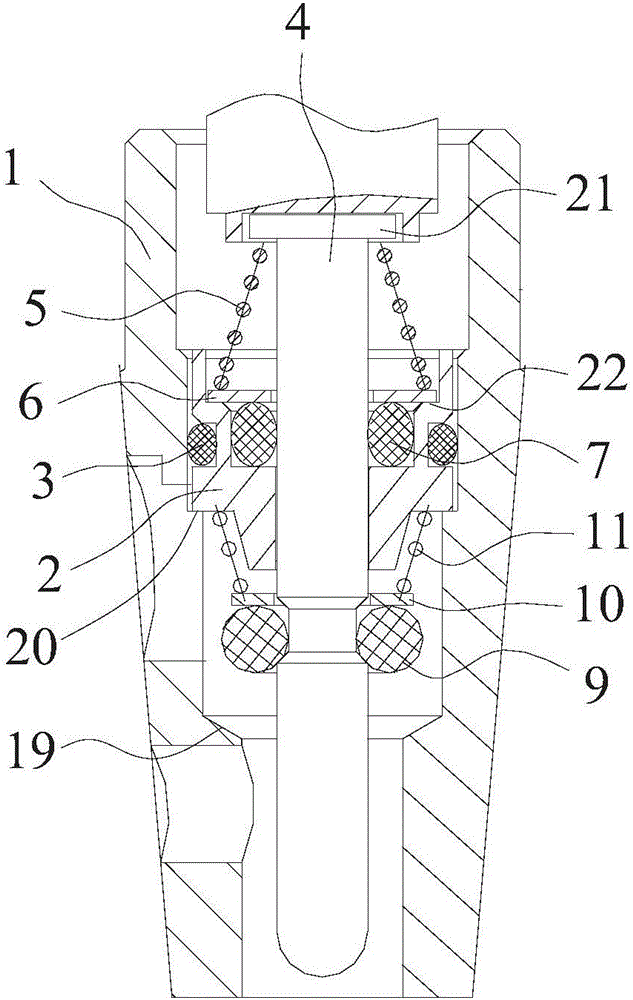

[0031] see figure 1 , figure 2 , a gas cock valve in this embodiment, including a valve body 14, a valve core 1 is fitted in rotation in the valve body 14, the valve core 1 is a hollow structure, the inside is a gas distribution chamber, and the inner axial bottom end of the valve core 1 is an inlet The air hole 8 is provided with an air supply solenoid valve matched with the air inlet 8 in the valve body, and the side wall of the valve body 14 is provided with an outer ring air supply hole 15 and an inner ring air supply hole 16 .

[0032] A valve stem 4 is inserted inside the valve core 1, and the valve stem 4 can be rotated so that the outer ring air supply hole 15 and the inner ring air supply hole 16 correspond to the corresponding air holes on the valve body. In order to ignite, the valve stem 4 can also move axially , the valve stem 4 is provided with a fixed plate 13, and the valve body 14 is provided with a limiting plate 12 for blocking the fixed plate 13, only whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com