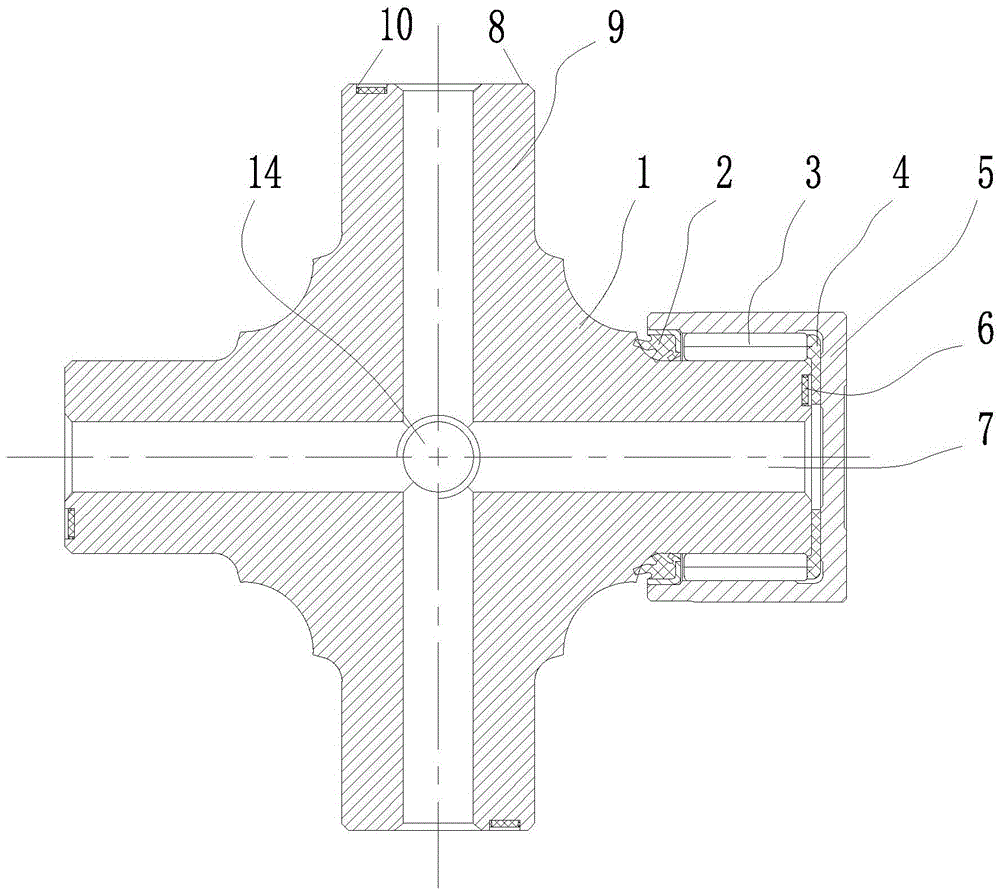

Intelligent maintenance type crossed shaft universal joint

A cross-axis universal and intelligent maintenance technology, which is applied in the field of automobile transmission parts, can solve problems such as vehicle adverse events, inability to grasp the wear and tear of the universal joint in real time, and inability to repair and maintain the universal joint, so as to avoid automobile traffic accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

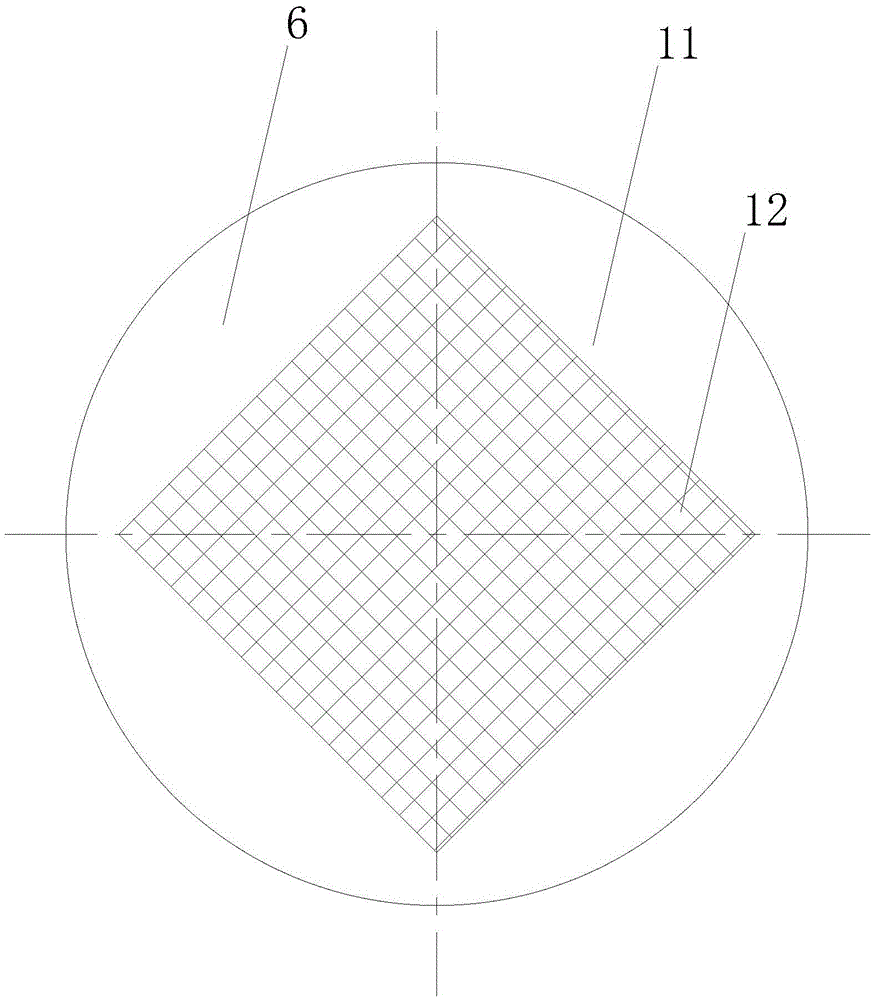

Embodiment 2

[0025] The difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, the sensor insert 11 is in the shape of a cover, and the bottom of the cover is located on the side of the end face of the shaft head 9, while the wireless chip sensor assembly 6 in Embodiment 2 is not covered with Separator for lubricating oil. Compared with the first embodiment, the second embodiment is easier to assemble the wireless chip sensor component 6 and install the wireless chip sensor component 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com