One-way valve and metering pump

A technology of one-way valve and valve membrane, which is applied in the direction of pump components, variable displacement pump components, and components of pumping devices for elastic fluids, etc., which can solve the problem of affecting pump accuracy, restricting the installation direction of metering pumps, and increasing the cost profile Size and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings of the description.

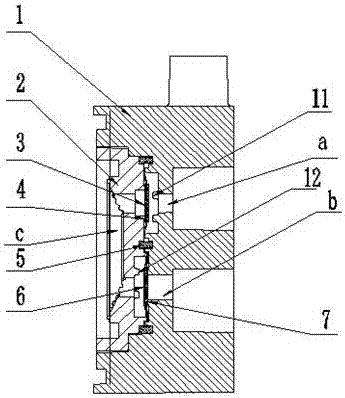

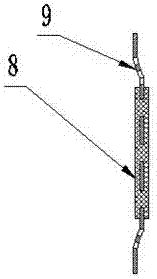

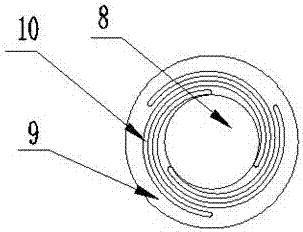

[0019] Such as figure 1 and figure 2 As shown, the one-way valve of the present invention includes a valve body 1, a valve plate 2, a liquid discharge chamber a, a liquid inlet chamber b and an inner chamber c, and a first valve diaphragm for isolating the liquid discharge chamber a and the inner chamber c 3. The second valve diaphragm 6 used to isolate the liquid inlet chamber b and the inner chamber c; the first valve diaphragm 3 and the second valve diaphragm 6 are both arranged between the valve plate 2 and the valve body 1, the first valve diaphragm The diaphragm 3 has the same structure as the second valve diaphragm 6 and is composed of a stainless steel plate 9 and a rubber sheet 8. The rubber sheet 8 is symmetrically arranged on both sides of the stainless steel plate 9. The stainless steel plate 9 is also provided with a penetrating flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com