Wheel-to-flow force retractable rolling shutter trolley and power generation system

A rolling shutter and flow force technology, applied in the field of hydraulic and wind power equipment, can solve problems such as unsatisfactory and underutilized hydraulic and wind power resources, and achieve low maintenance costs and strong anti-destructive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

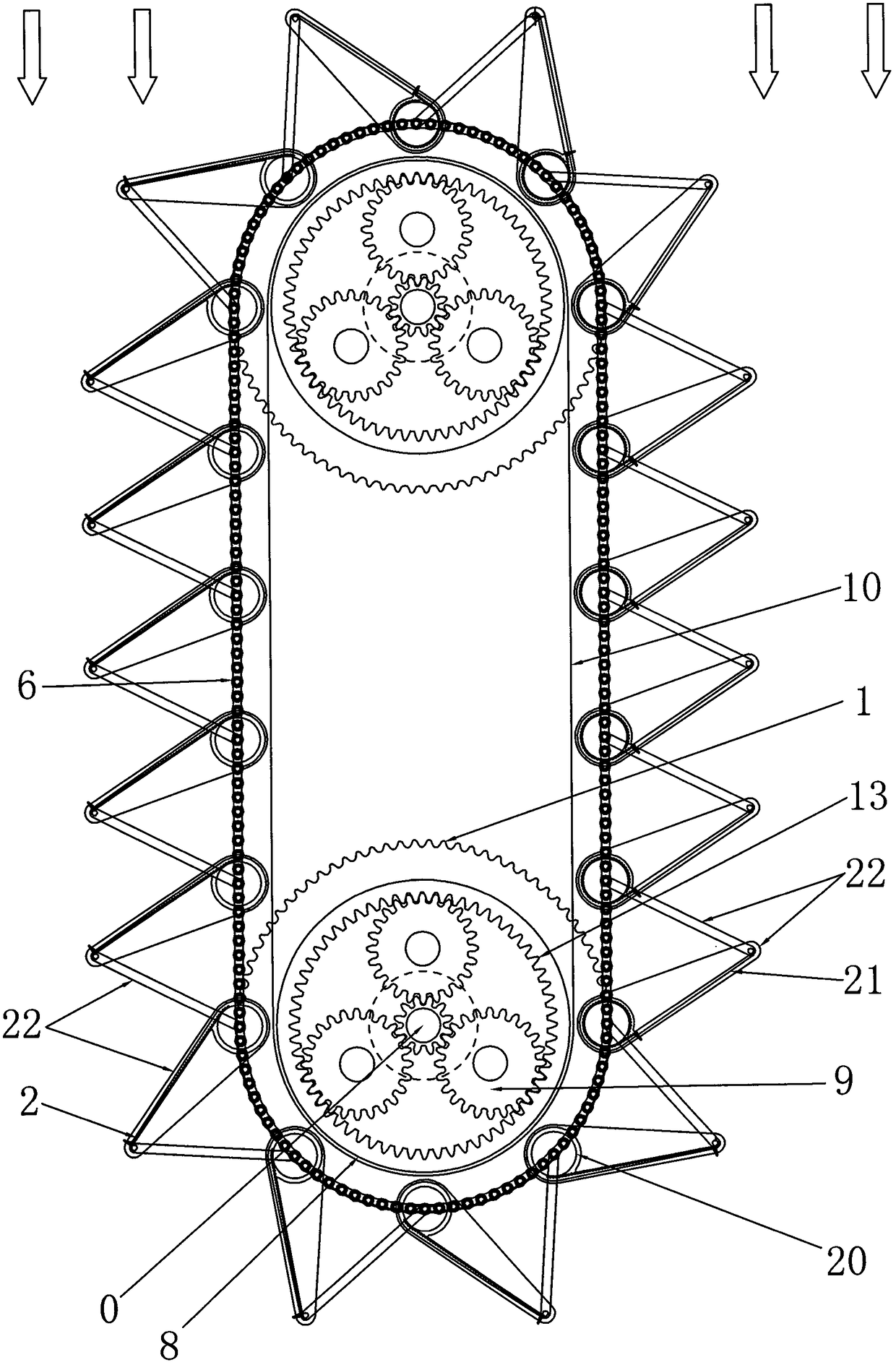

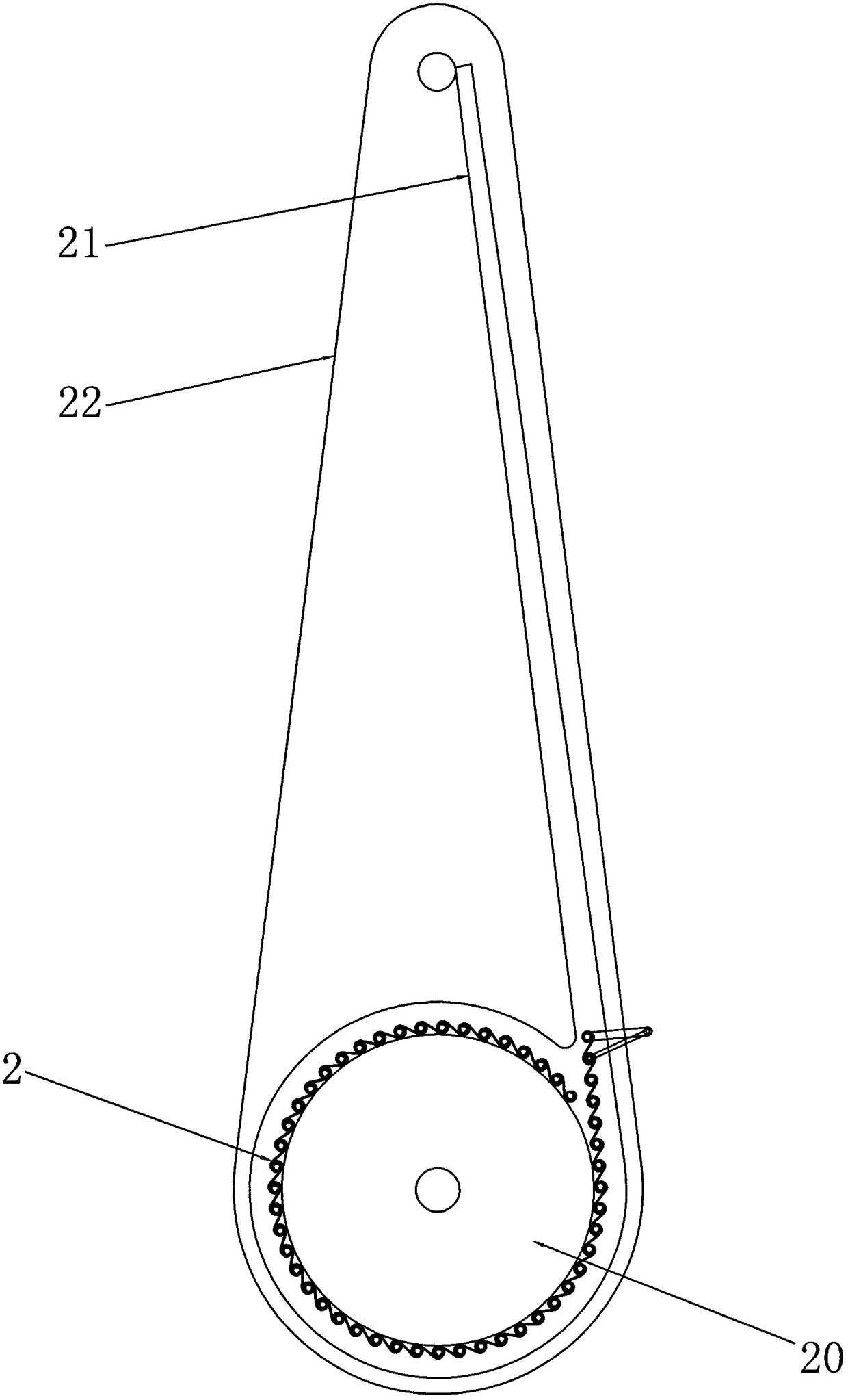

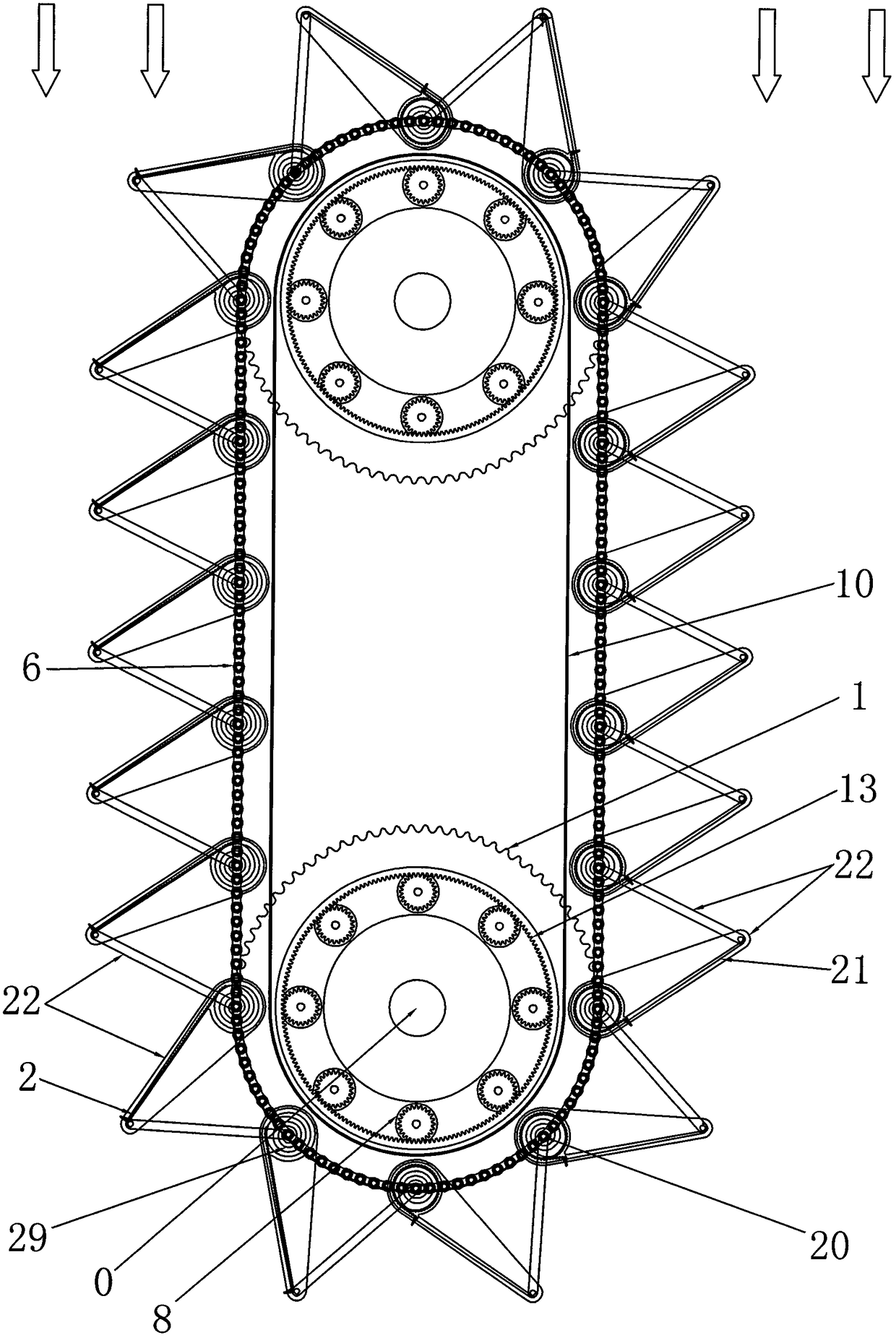

[0043] A kind of wheel direction flow power telescopic rolling shutter flow board car, such as figure 1 , 3 , 5, 6, and 13, it includes: a runner 1, a central shaft 0, a chain belt 6, a roller blind 2, a roller blind bracket 22, a reel 20 and a frame 10; the central shaft 0 is the runner 1 The rotating central axis of the rotating wheel 1 is coaxially socketed; the rotating wheel 1 is a sprocket, a gear or a belt pulley, two coaxial ones and two groups rotate in parallel with the central axis 0 on both sides of the frame 10 end; the fixed-point rotation of the spool 20 is at one end of the shutter bracket 22, and its axis is parallel to the central axis 0 of the runner 1 or its axis is perpendicular to the central axis 0 of the runner 1; the chain The belt 6 links two runners 1; the plurality of roller blind brackets 22 are fixed and hinged on the chain belt 6; 2 Connect the reel 20 and use the roller blind 2 to slide on the slide track 21 of the roller blind bracket 22: the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com