Afterheat intelligent self-adaption turbine power generation system

A power generation system, self-adaptive technology, applied in steam generation, engine components, steam generation devices, etc., can solve problems such as energy waste, and achieve the effects of convenient use, simple structure, and stable control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

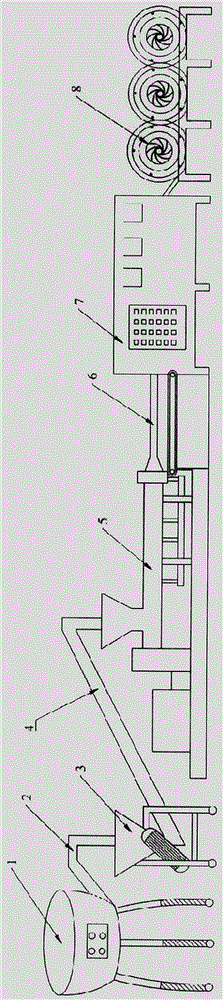

[0015] Such as figure 1 Shown: waste heat intelligent adaptive turbine power generation system, its structure includes: boiler 1, first-level connecting pipe 2, connecting cylinder 3, second-level connecting pipe 4, heat storage cylinder 5, third-level connecting pipe 6, self-adaptive control cabinet 7 , generator set 8; the boiler 1 is a vertical coal-fired type, the side of the boiler 1 is connected to one end of the primary connecting pipe 2 by welding, and the other end of the primary connecting pipe 2 is connected to the connecting cylinder 3 by welding, and the connecting cylinder 3 One end of the secondary connection pipe 4 is connected by welding, and the other end of the secondary connection pipe 4 is connected to the inlet of the heat storage cylinder 5. The heat storage cylinder 5 is a cylindrical cylinder structure placed horizontally, and the diameter of the outlet section of the heat storage cylinder 5 is smaller than that of the entrance. The diameter of the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com