Automatic control system and method of pre-tensioning prestress construction

An automatic control system and prestressing technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as inability to standardize production, insufficient tensioning steel strands, and inaccurate readings, so as to ensure quality stability and Standardize production, avoid table look-up conversion, and ensure the effect of quality standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

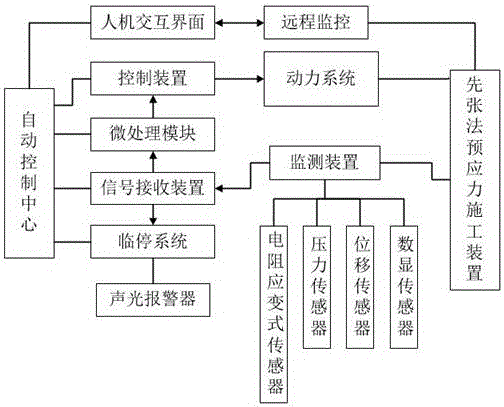

[0040] Such as figure 1 As shown, the automatic control system for pretensioned prestressed construction includes an automatic control center and a power system. The automatic control center is connected with a control device for controlling the power system. The power system is connected to the pretensioned prestressed construction device. The construction device is set There is a monitoring device, which includes a resistance strain sensor for monitoring the tension parameters of the steel strand and a pressure sensor for monitoring the pressure of the power system. The control center is also equipped with a signal receiving device and a micro-processing module, and the signal After the receiving device receives the original data signal fed back from the monitoring device, it analyzes and processes it through the micro-processing module, and then converts it into a control signal and sends it to the control device. The tensioning process is completed through the control of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com