Manufacturing method of special pavement precast slab for simulating ice surface in tire test field

A technology for simulating ice surfaces and manufacturing methods, applied to special pavements, roads, roads, etc., can solve problems affecting the structural parameters of concrete prefabricated components, and achieve the effect of being operable, easy to operate, and avoiding bumps and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

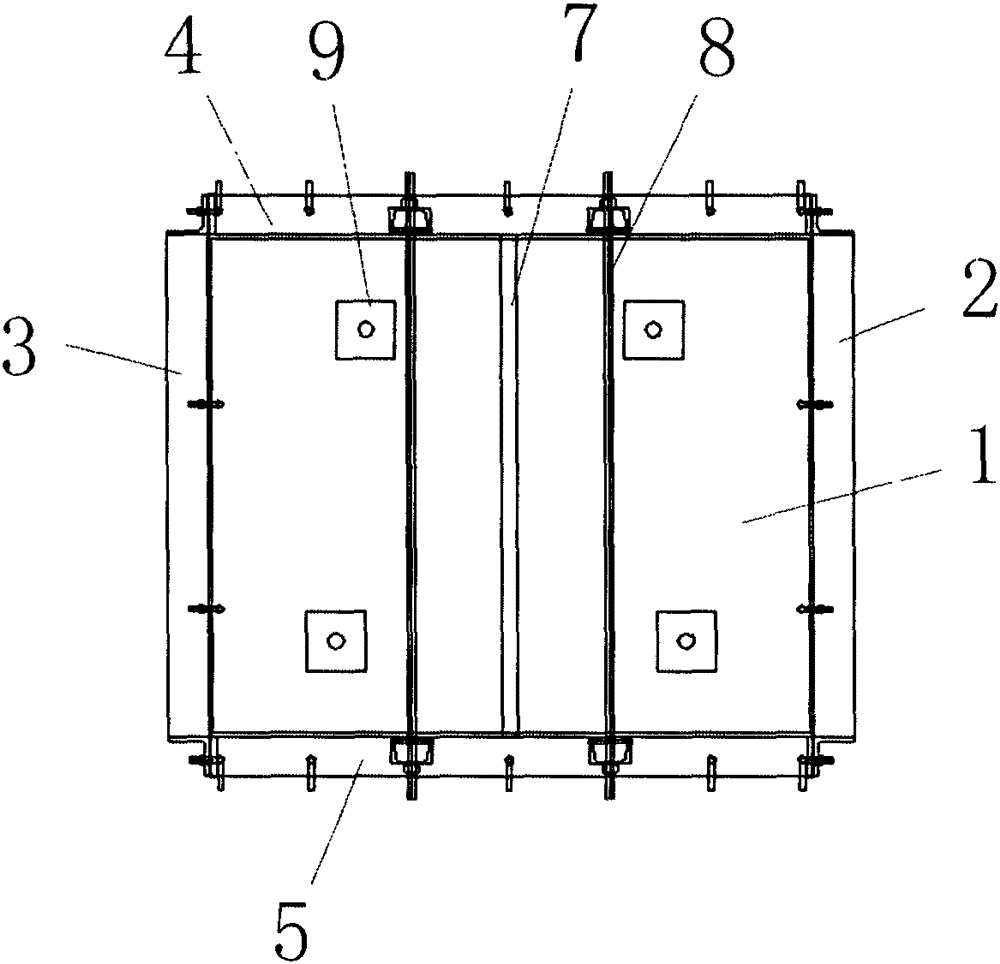

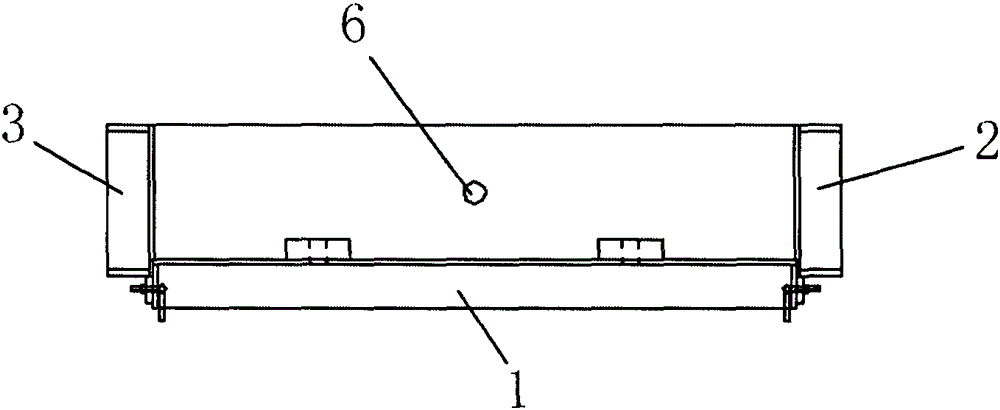

[0020] Such as figure 1 , 2 As shown, the process of the present invention can be divided into two stages, one is the installation and manufacturing process of the precast slab steel formwork; the other is the pouring and manufacturing process of the precast slab.

[0021] The first stage:

[0022] The precast plate steel formwork is a rectangular structure, which is composed of a bottom plate 1 and four side plates 2, 3, 4, 5 assembled. Steel form bottom plate 1 is made of 12mm thick steel plate with a size of 1200×1600mm, and the back side is made of 8# channel steel welded frame. Before production, the frame must be welded separately on a special platform (flatness less than 1mm). After checking that the flatness of the frame is less than 2mm, the frame and the bottom plate are welded and connected. When welding the frame, it must be strictly noted that the leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com