Simple-support variant-continuous structure of steel-ultrahigh performance concrete light composite beam and construction method for same

An ultra-high performance, structural construction technology, applied in bridges, bridge parts, bridge materials, etc., can solve the problems of concrete cracking and unsuitable use, and achieve the effect of prolonging the service life, improving the stress condition, and improving the bending and tensile performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

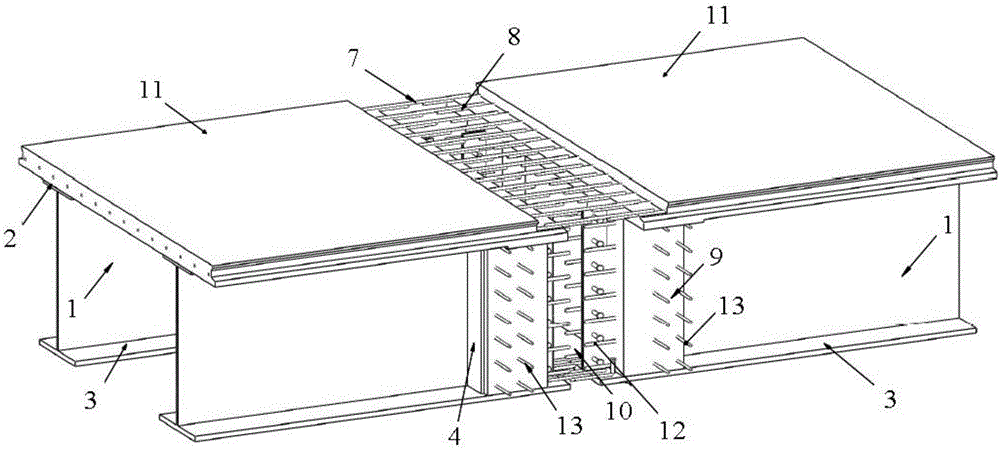

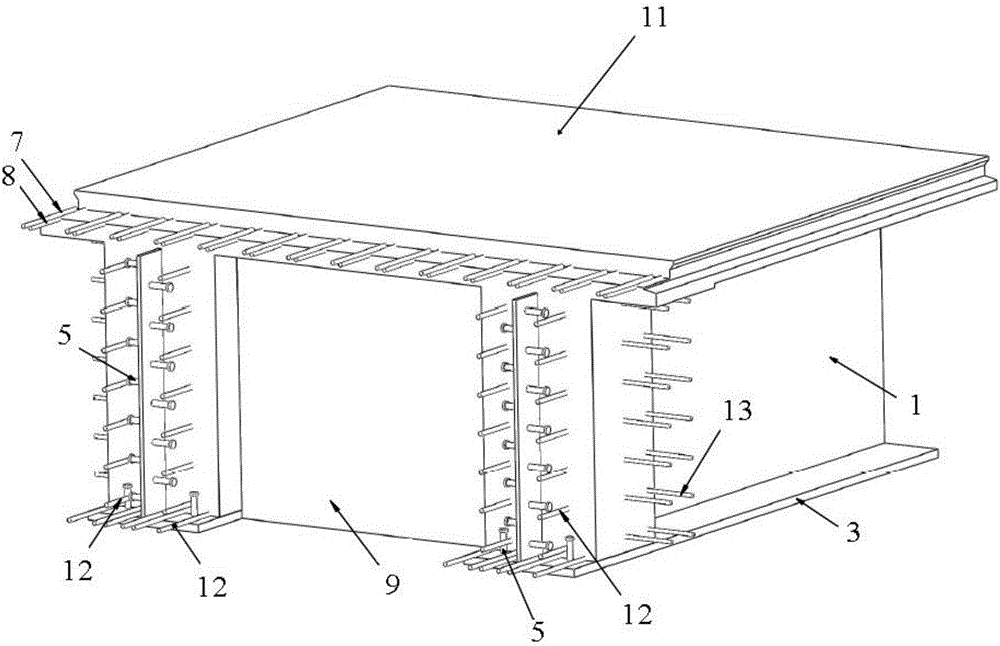

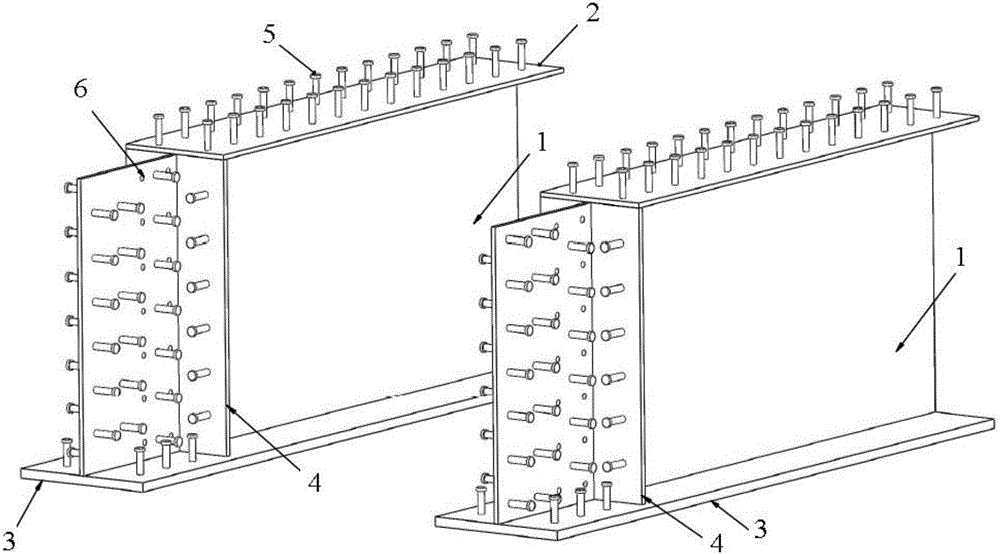

[0046] An embodiment of the steel-ultra-high performance concrete light composite beam simply supported variable continuous structure structure of the present invention, the steel-ultra high performance concrete light composite beam simply supported variable continuous structure structure is mainly used in steel-ultra high performance concrete The construction process of light composite girder bridge from simply supported system to continuous system. The structural diagram of the structure is shown in Figure 1-Figure 8 shown by Figure 1-Figure 8 It can be seen that the steel-ultra-high-performance concrete light-weight composite beam simply supported variable continuous structure mainly includes two-span steel-ultra-high-performance concrete light-weight simply-supported beams and two-span steel-ultra-high-performance concrete light-weight simply The cast-in-place ultra-high performance concrete connection part 10 of the beam. Among them, the steel-ultra-high-performance c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com