Production line for culturing plant stem cells on large scale

A plant stem cell and production line technology, applied in biological material sampling methods, tissue cell/virus culture devices, specific-purpose bioreactors/fermenters, etc. Wastewater and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

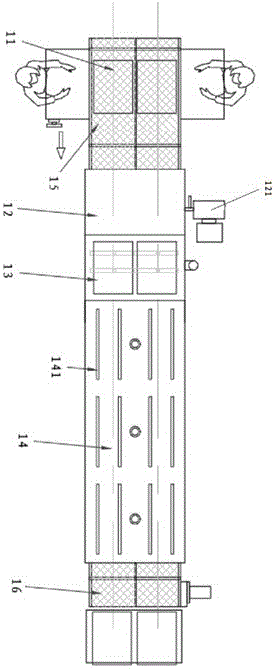

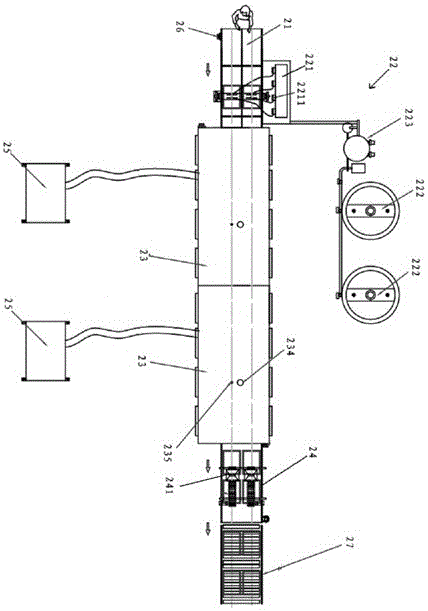

[0024] Such as Figure 1 to Figure 3 As shown, a production line for large-scale cultivation of plant stem cells includes a tray cleaning and drying line 1 and a medium filling freezing inoculation line 2; the tray cleaning and drying line 1 includes a first conveyor belt 11, a cleaning chamber 12, a water blowing warehouse 13 and drying warehouse 14, the first conveyor belt 11 passes through the cleaning warehouse 12, the water blowing warehouse 13 and the drying warehouse 14 in turn, and the cleaning warehouse 12 is provided with several rows of nozzles 121, and the nozzles The angle can be adjusted, several air knives are arranged in the water blowing chamber, the drying chamber 14 is closely connected with the water blowing chamber 13, and several heat pipes 141 are arranged inside the drying chamber 14; the medium filling The freezing ino...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com