Maglev weft insertion automatic loom

A loom and weft insertion technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of complex shuttle changing mechanism, labor-intensive, and high consumption of machine materials, shortening the process flow and speeding up the shuttle changing. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

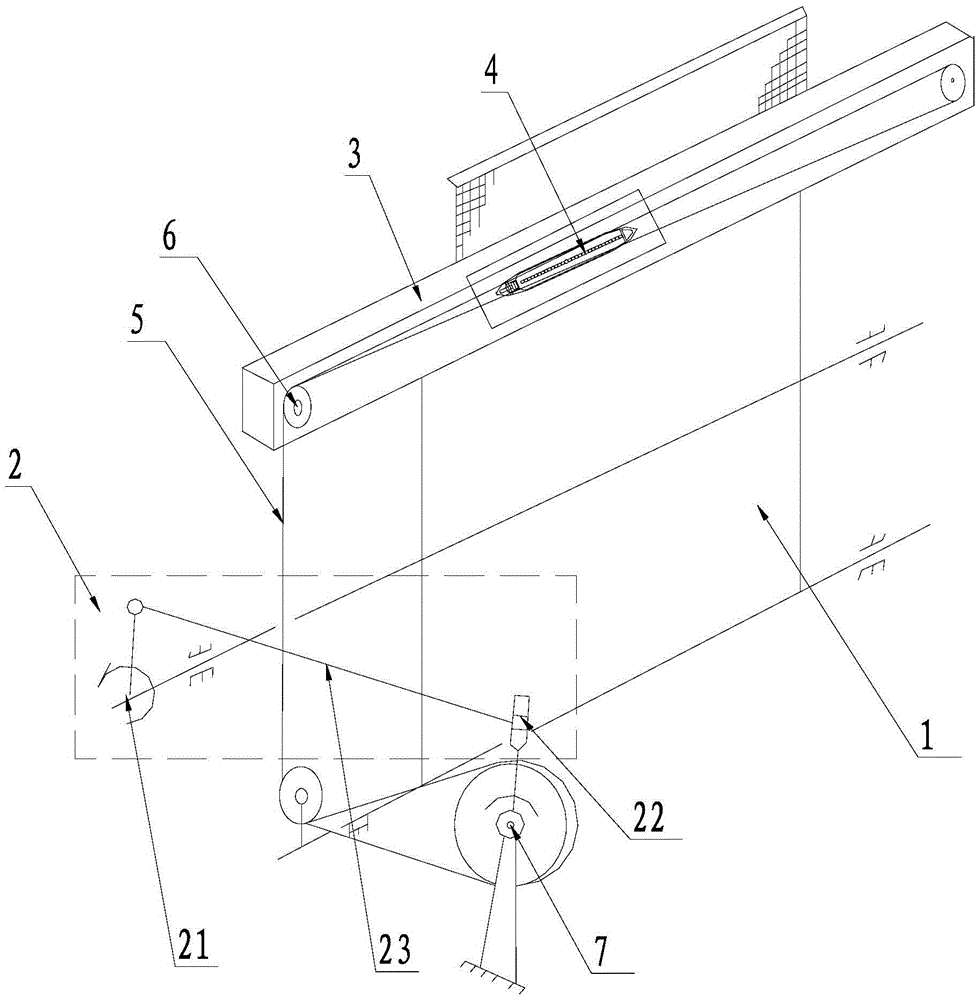

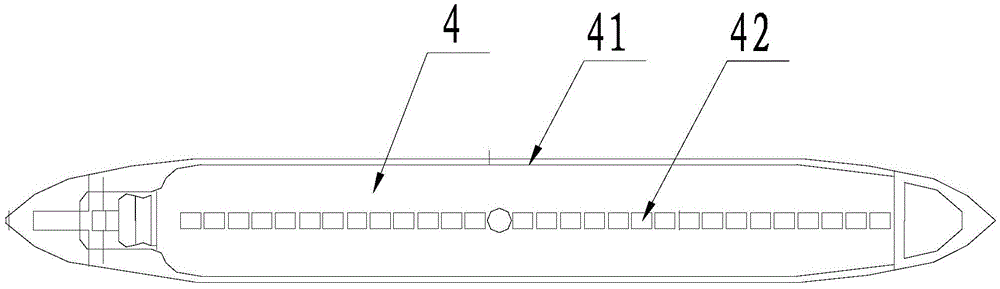

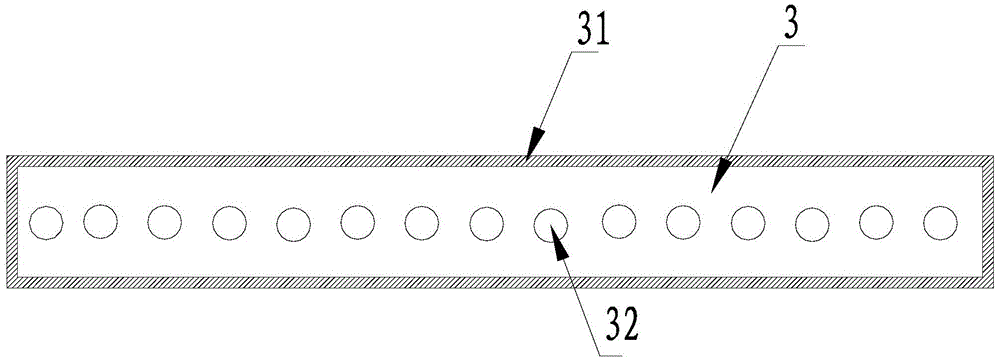

[0022] The embodiment of the present invention relates to a magnetic levitation weft insertion automatic loom, which includes a frame 1, a guide rail 3, a crank rocker mechanism 2 and a weft insertion shuttle 4, wherein the crank rocker mechanism 2 includes a rocker 21, a crank 22 and a The connecting rod 23 between the rod 21 and the crank 22, the crank rocker mechanism 2 is fixedly connected with the frame 1 by the crank 22, and the crank rocker mechanism 2 is connected with the weft insertion shuttle 4 by the weft insertion wire rope 5. In the present invention, The guide rail 3 includes a large gantry frame 31 and a guide rail magnetic sheet 32 fixed on the large gantry frame 31. The weft insertion shuttle 4 includes a shuttle guide sheet 41 and a shuttle guide magnetic sheet 42. The shuttle guide magnetic sheet 42 is fixed on the bottom of the shuttle guide sheet 41. , the present invention adopts the principle of magnetic levitation, so the polarity of the opposite surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com