Method for purifying peony seed shell pigment by using macroporous resin

A technology of peony seed shell and macroporous resin, which is applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of refining the purification method of macroporous resin and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

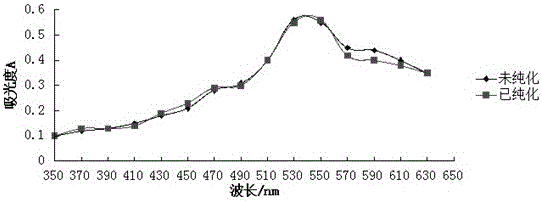

Embodiment 1

[0031] Weigh 5g peony seed shell powder as raw material (through a 60-mesh sieve), add 175ml of ethanol solution with a concentration of 50% (that is, the ratio of liquid to material is 1:35), and place it in an ultra-high pressure environment of 200Mpa, and the continuous holding time is After 15 minutes, the obtained material was filtered to obtain a pigment filtrate, and then the filtrate was rotary evaporated to remove the extractant ethanol and part of the water, and evaporated to 1 / 2 of the volume of the original filtrate to obtain a peony seed shell pigment concentrate. Take by weighing 1.00g peony seed shell powder, join in the 50% ethanol solution of 40ml, extraction pressure is 200MPa, and holding time is 20min, observe the color of extract solution, filter extract solution, and its constant volume to 50ml. The absorbance value at 380-620nm was measured with an ultraviolet spectrophotometer, and the optimum absorption wavelength of the extracted pigment was determine...

Embodiment 2

[0038] Weigh 5g of peony seed shell powder as raw material (through 80 mesh sieve), add 200ml of ethanol solution with a concentration of 50% (that is, the ratio of liquid to material is 1:40), and place it in an ultra-high pressure environment of 200Mpa, and the continuous holding time is After 20 minutes, the obtained material was filtered to obtain a pigment filtrate, and then the filtrate was rotary evaporated to remove the extractant ethanol and part of the water, and evaporated to 1 / 3 of the original filtrate to obtain a peony seed shell pigment concentrate. Take by weighing 1.00g peony seed shell powder, join in the 50% ethanol solution of 40ml, extraction pressure is 200MPa, and holding time is 20min, observe the color of extract solution, filter extract solution, and it is settled to 50ml. The absorbance value at 380-620nm was measured with an ultraviolet spectrophotometer, and the optimum absorption wavelength of the extracted pigment was determined to be 520nm. In s...

Embodiment 3

[0045] Weigh 5g peony seed husk as raw material (through a 100-mesh sieve), add 225ml of ethanol solution with a concentration of 50% (that is, the ratio of liquid to material is 1:45), and place it in an ultra-high pressure environment of 200Mpa, and the continuous pressure holding time is After 25 minutes, the obtained material was filtered to obtain a pigment filtrate, and then the filtrate was rotary evaporated to remove the extractant ethanol and part of the water to obtain a peony seed shell pigment concentrate. Take by weighing 1.00g peony seed shell powder, join in the 50% ethanol solution of 40ml, extraction pressure is 200MPa, and holding time is 20min, observe the color of extract solution, filter extract solution, and its constant volume to 50ml. The absorbance value at 380-620nm was measured with an ultraviolet spectrophotometer, and the optimum absorption wavelength of the extracted pigment was determined to be 520nm, and the absorbance of the pigment solution wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com