Prefabricated component maintenance system with mobile maintenance warehouse

A prefabricated component and maintenance system technology, which is applied in the direction of manufacturing tools, conveyor objects, auxiliary molding equipment, etc., can solve problems such as the difficulty of relocating production lines, and achieve the effects of reducing construction costs, facilitating disassembly and relocation, and flexible process layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

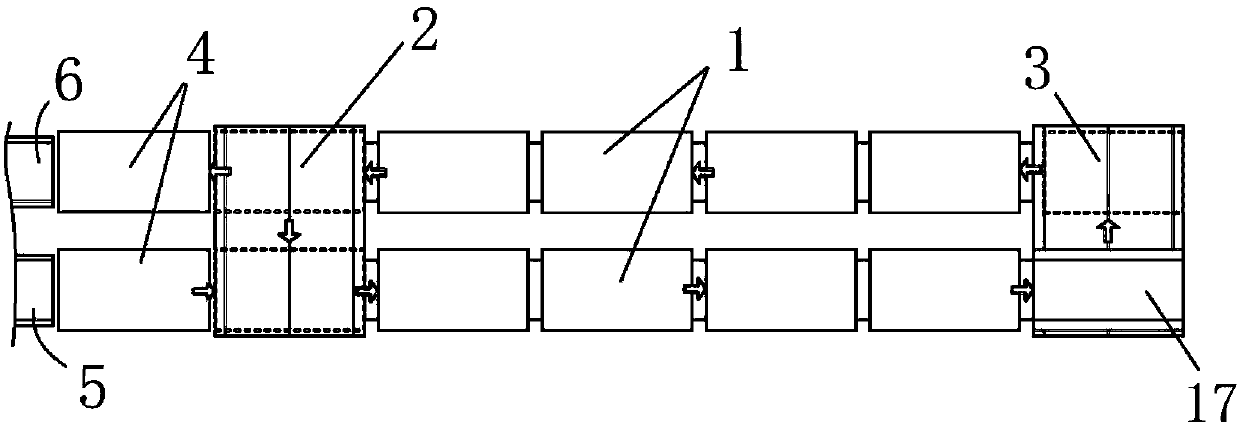

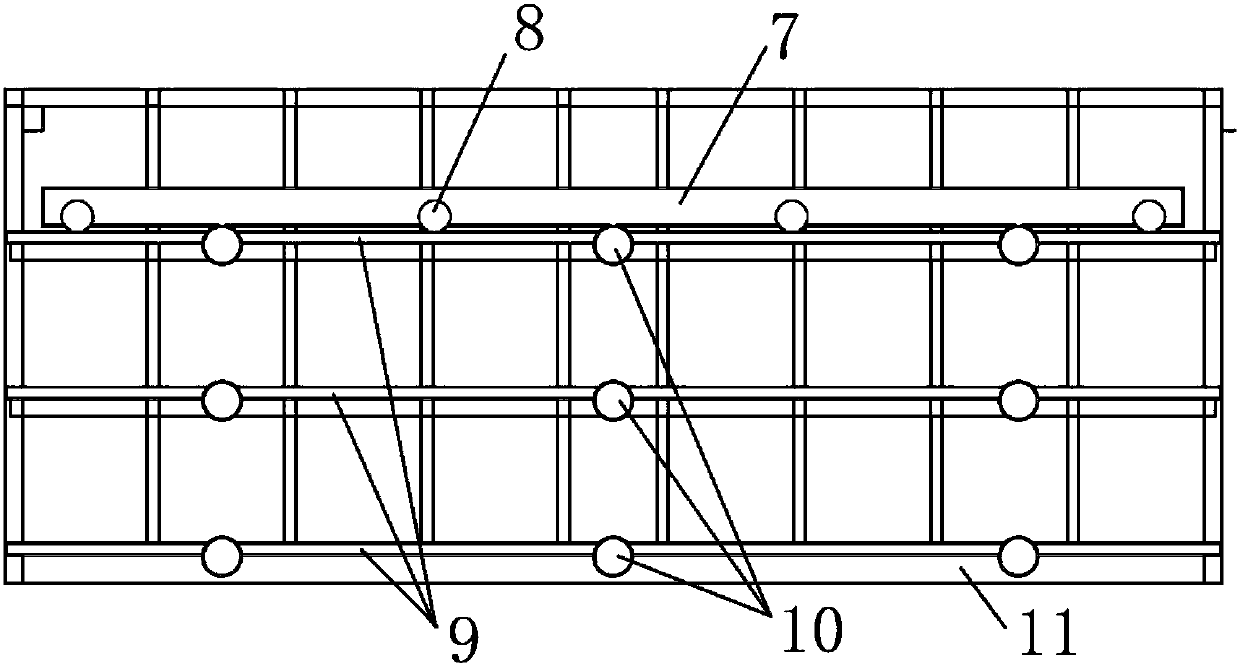

[0036] like Figure 1~2 As shown, the prefabricated component production line usually includes a main production line 6 and a secondary production line 5 arranged in parallel. During production, the prefabricated component first enters the main production line 6, and on the main production line 6 along the conveying direction of the prefabricated component, edge removal molders are sequentially arranged. Station, hoisting station, line drawing oil injection station, side mold installation station, steel bar installation station, embedded parts installation station, fabric vibrating station, insulation board and connecting parts installation station, etc. After the output of the main production line 6, it is transferred to the production sub-line 5. The production sub-line 5 is usually equipped with secondary reinforcement station, secondary fabric station, leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com