Machining method for cone seal head

A processing method and cone technology, applied in gas/liquid distribution and storage, pressure vessels, fixed-capacity gas storage tanks, etc., can solve the problems of product scrapping and cracking machine increase, and achieve good reliability and low product scrapping rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

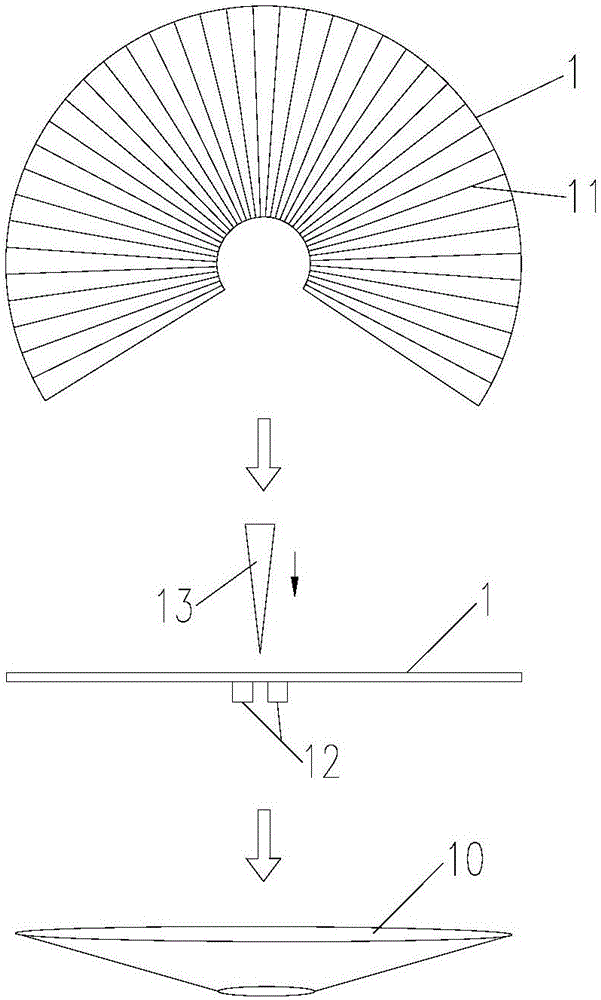

[0029] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

[0030] see Figure 2-Figure 6 As shown, the present invention provides a kind of processing method of conical head, and it mainly comprises the following steps,

[0031] S10: blanking, cutting the plate according to the size of the designed cone head, forming the cone shell blank 1 with a fan-shaped structure and the hemming blank 2 with a fan-shaped structure respectively. The material of the cone shell blank 1 and the flanging blank 2 is selected as carbon steel.

[0032] S20: Plate rolling, drawing a reference line 11 on the cone shell blank 1, specifically as image 3 As shown, the number of reference lines 11 in this embodiment is 40, and the extension line of each refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com