Hydrogel photonic crystal microspheres, and preparation method and application thereof

A technology of photonic crystal microspheres and hydrogels, which is applied in the preparation of microspheres, microcapsule preparations, and material analysis through optical means, and can solve the problem of reducing the accuracy and applicability of hydrogel photonic crystals and making it difficult to prepare photonic crystals microspheres etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

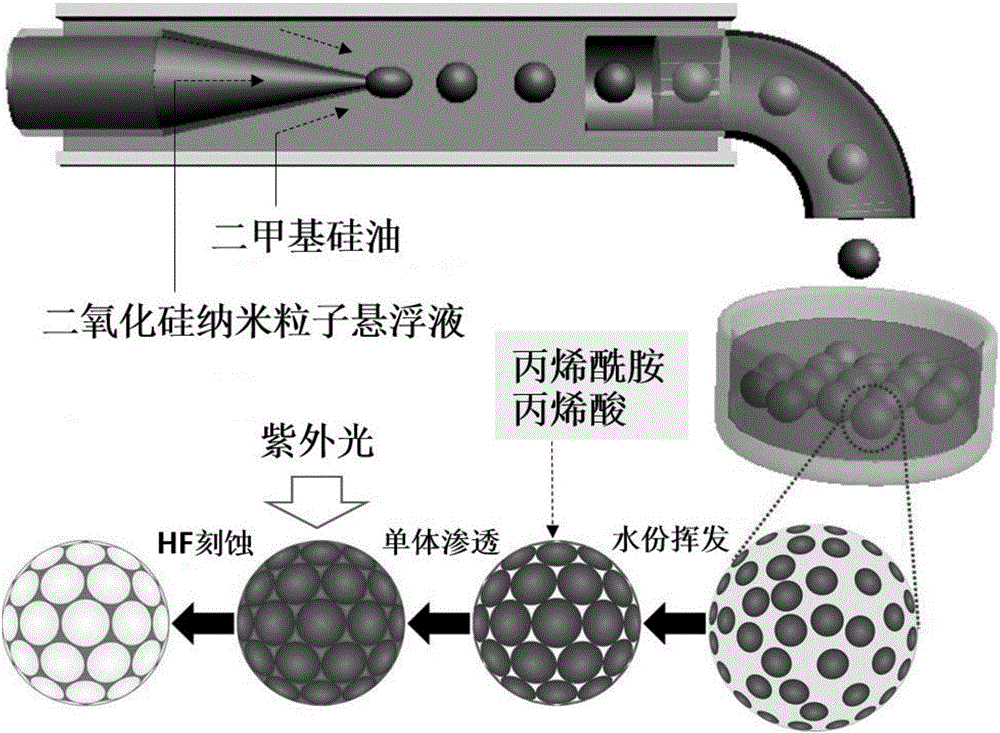

[0045] The preparation method of the photonic crystal microsphere comprises the following steps:

[0046] (1) Preparation of silica emulsion droplets: uniformly disperse tetraethyl orthosilicate and ammonia water in ethanol, and stir at constant temperature for 6 hours; after the reaction, centrifugally purify to obtain silica nanoparticles, and silica nanoparticles The particles are dispersed in water to obtain a suspension; the particle size of the silica nanoparticles in the suspension is 50-500nm, preferably 200-300nm (especially 200nm-250nm), and the mass concentration is 5-20%, preferably 10-15 %; Using microfluidic technology, the aforementioned silica nanoparticle suspension is used as the dispersed phase, and under the shear force of the continuous phase simethicone oil, the dispersed phase forms monodisperse emulsion droplets. The flow rate of the internal water phase is 50-500 μL / h, and the flow rate of the continuous phase is 2000-6000 μL / h; the internal diameter o...

Embodiment 1

[0057] The preparation method of the inverse opal structure hydrogel photonic crystal microsphere in this embodiment comprises the following steps:

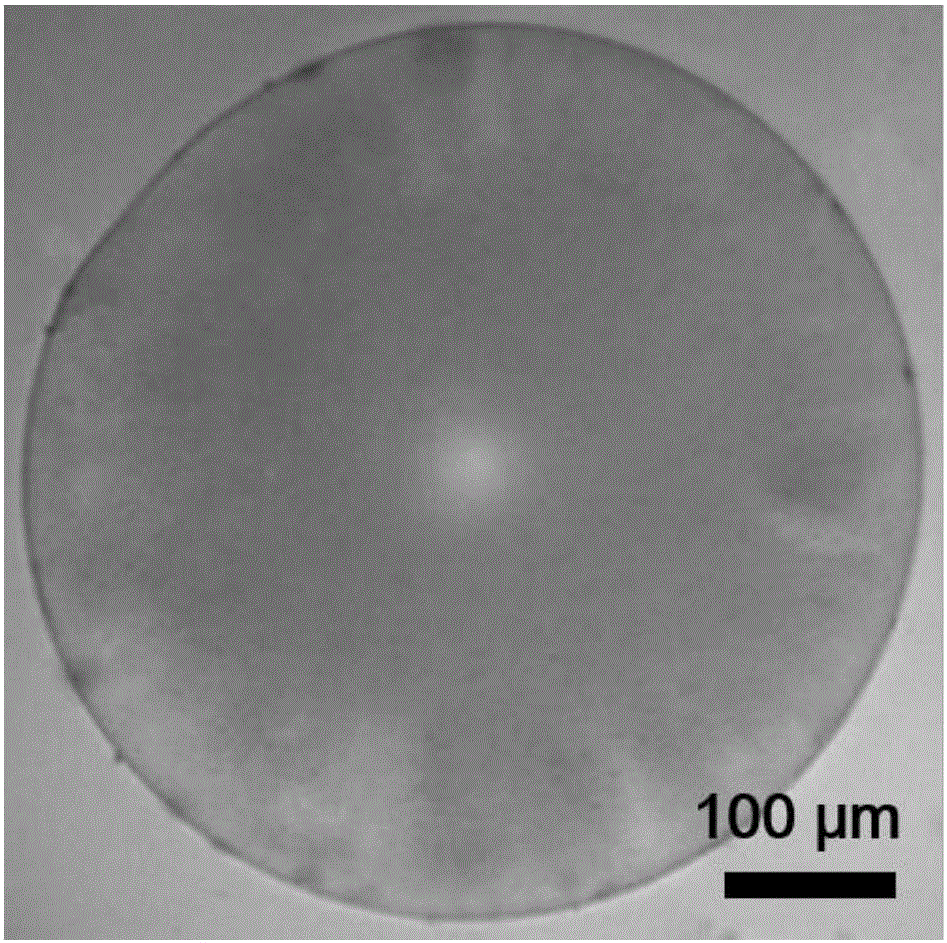

[0058] (1) Preparation of silica emulsion droplets: uniformly disperse tetraethyl orthosilicate and ammonia water in ethanol, and stir at constant temperature for 6 hours; after the reaction, centrifugal purification is obtained to obtain silica nanoparticles, and the silica nanoparticles Disperse in water to obtain a suspension; the particle size of the silica nanoparticles in the suspension is 245nm, and the mass concentration is 10%; using microfluidic technology, the aforementioned silica nanoparticle suspension is used as the dispersed phase, and in Under the shear force of the continuous phase simethicone, the dispersed phase forms monodisperse emulsion droplets. The flow rate of the dispersed phase is 300 μL / h, and the flow rate of the continuous phase is 3000 μL / h; the inner diameter of the internal capillary used in the ...

Embodiment 2

[0065] In this embodiment, the preparation method of the inverse opal structure hydrogel photonic crystal microsphere comprises the following steps:

[0066] (1) Preparation of silica emulsion droplets: uniformly disperse tetraethyl orthosilicate and ammonia water in ethanol, and stir at constant temperature for 6 hours; after the reaction, centrifugally purify to obtain silica nanoparticles, and silica nanoparticles The particles are dispersed in water to obtain a suspension; the particle size of the silica nanoparticles in the suspension is 245nm, and the mass concentration is 10%; using microfluidic technology, the aforementioned silica nanoparticle suspension is used as the dispersed phase, Under the shear force of the continuous phase simethicone, the dispersed phase forms monodisperse emulsion droplets. The flow rate of the dispersed phase is 300 μL / h, and the flow rate of the continuous phase is 3000 μL / h; the inner diameter of the internal capillary used in the microfl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com