Automatic temperature control system of gas water heater

A gas water heater and gas technology, which is used in fluid heaters, adjusting fuel supply, combustion methods, etc., can solve problems such as user burns, inability to comply with safety regulations, and inability to achieve real-time adjustment, avoiding burns, reducing inventory and The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

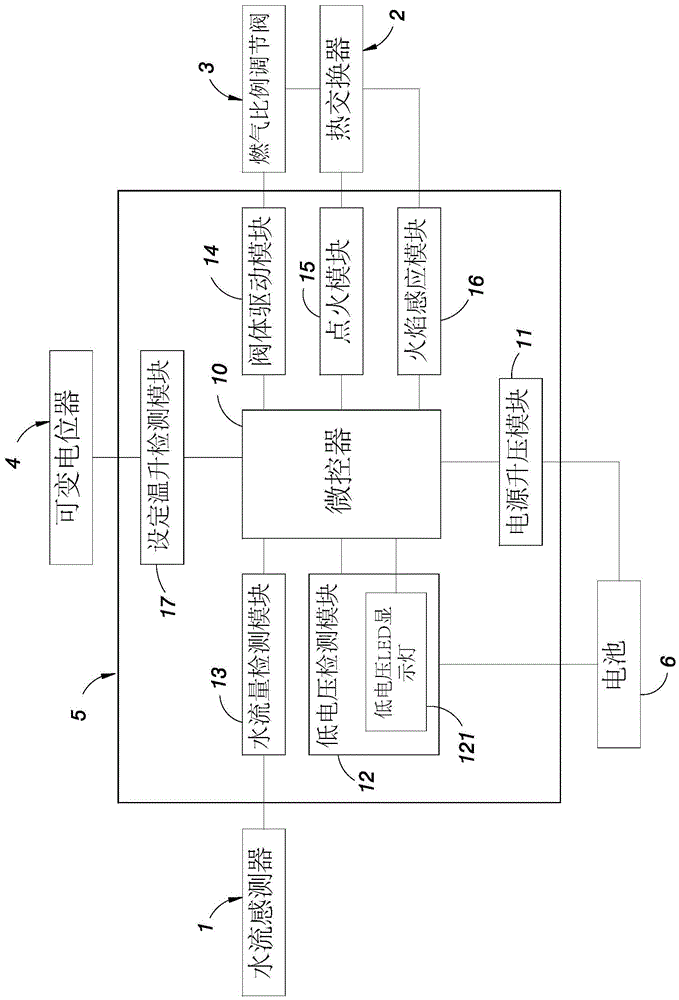

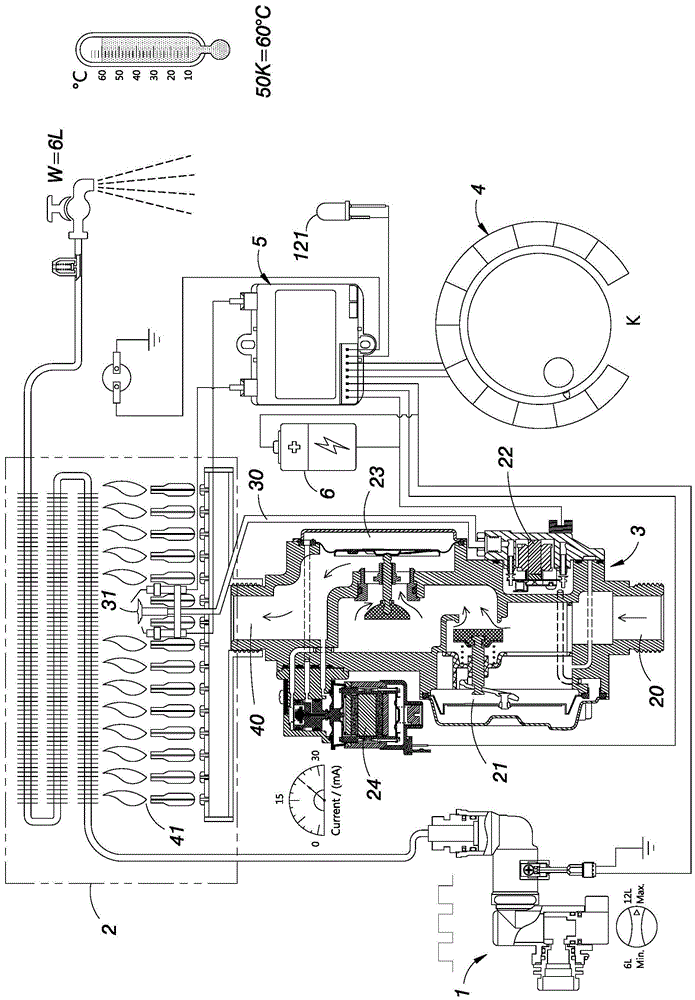

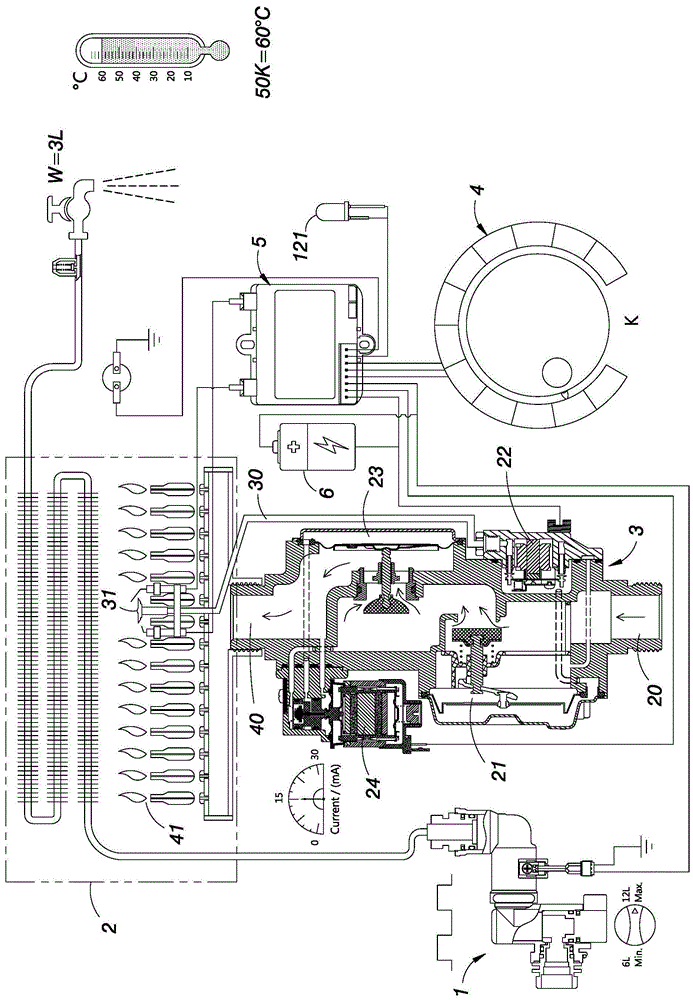

[0027] Such as Figure 1-2 As shown, the present invention is an automatic temperature control system applied in a gas water heater, which can control the gas flow rate according to the water flow rate, so that the gas flow rate can heat the water flow to the selected temperature rise value selected by the user without additional installation Temperature sensor; the automatic temperature control system includes: a water flow sensor 1 capable of detecting water flow, a heat exchanger 2 capable of heating the water flow, a gas proportional regulating valve 3 for supplying the gas required for combustion of the heat exchanger 2, A variable potentiometer 4 for users to select temperature rise, and a control unit 5 capable of receiving signals from the variable potentiometer 4 and the water flow sensor 1 .

[0028] The control unit 5 includes a microcontroller 10, a power boost module 11 capable of boosting the voltage of the battery 6 of the water heater for the operation of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com