High Power Acoustic Vibration Generator

An acoustic vibration and generator technology, applied in the direction of fluid, electric components, fuel supply, etc. which utilize vibration, can solve the problems of increasing equipment weight, high equipment repair rate, complex equipment, etc., to reduce equipment leakage rate, assembly The effect of simple structure and light equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

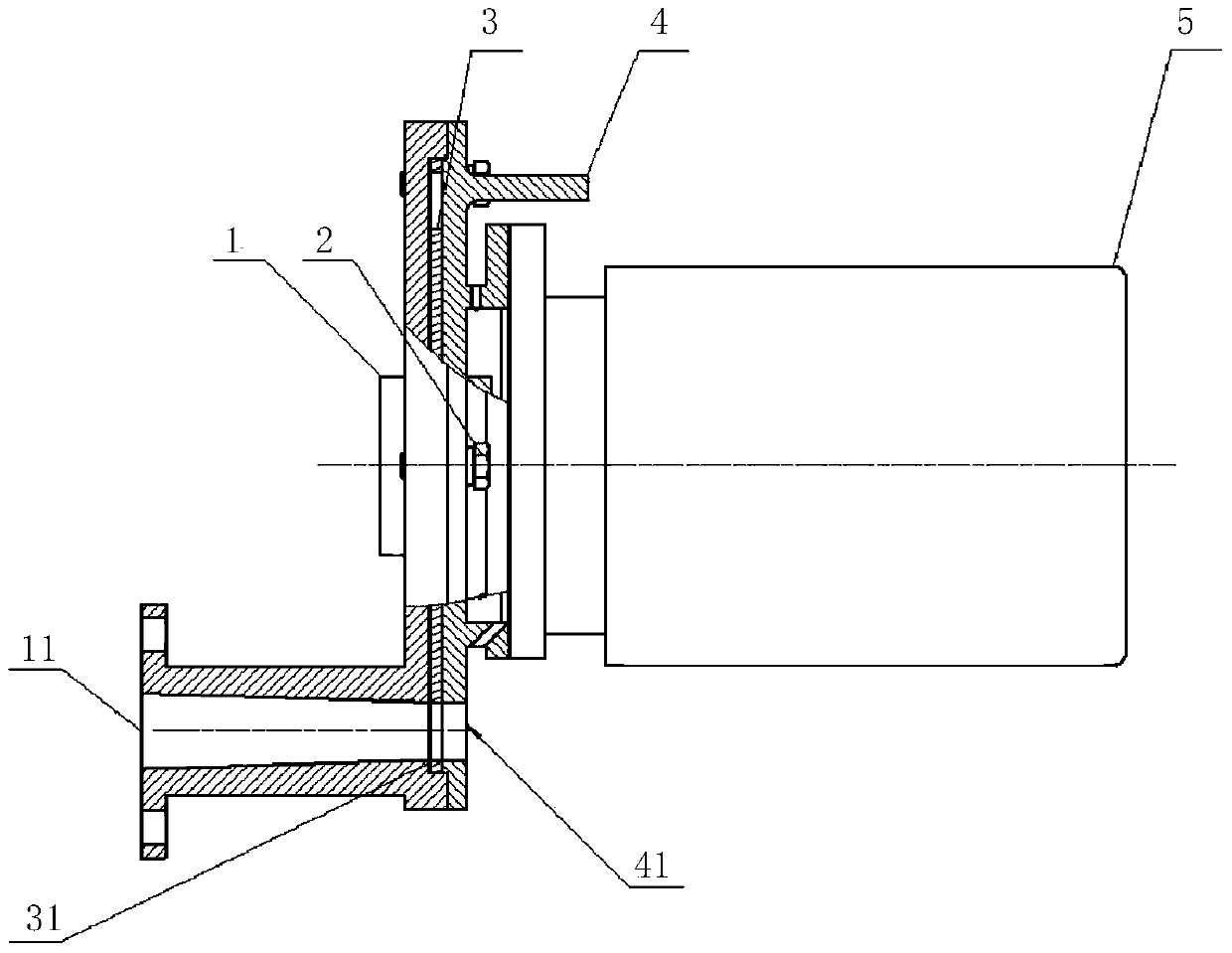

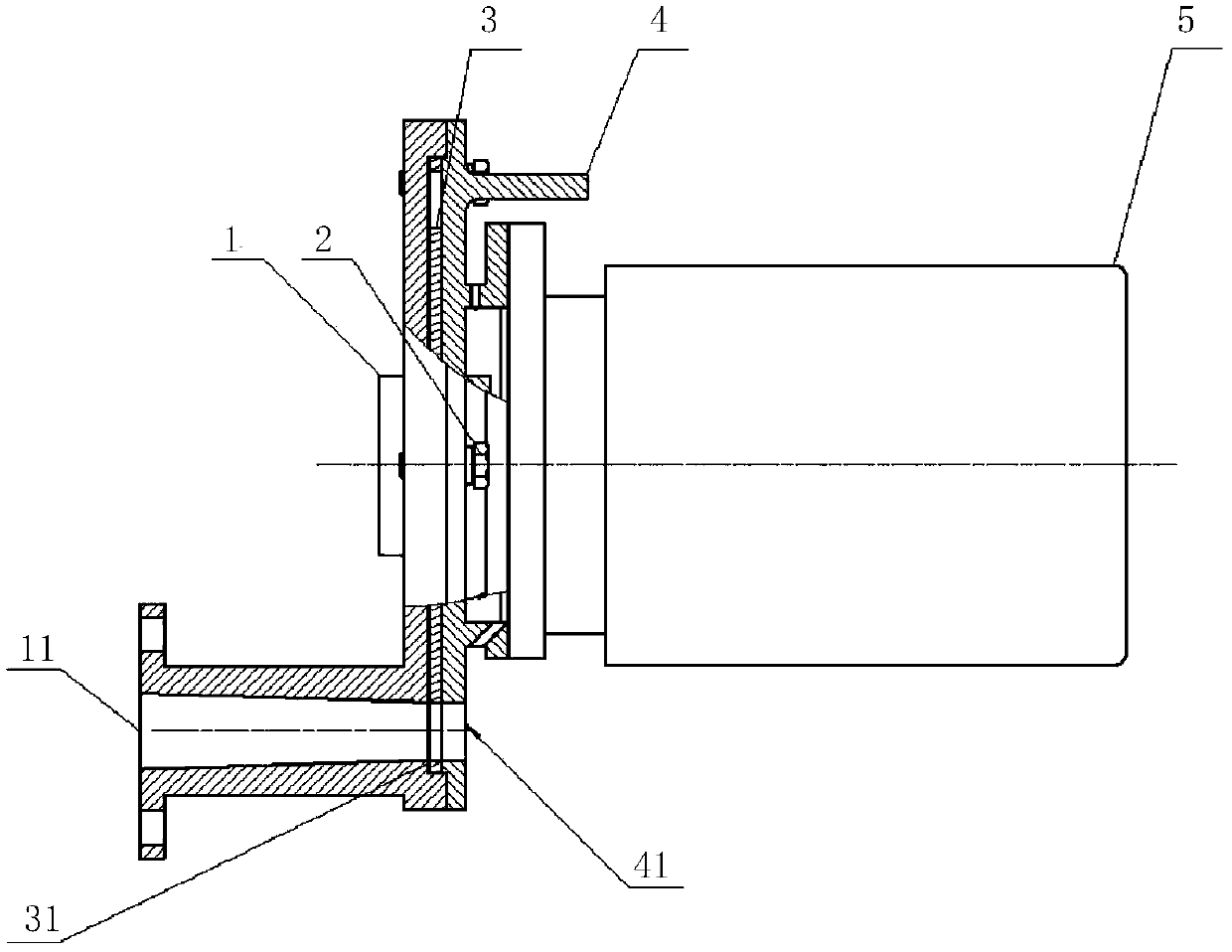

[0014] Such as figure 1 , The input disk 4, the sounding disk 3 and the output disk 1 are shown in cross-sectional view for clearly showing their structure. The high-power acoustic vibration generator of the present invention comprises input disk 4, sounding disk 3, output disk 1 and motor 5, and input disk 4 is provided with airflow input port 41, and output disk 1 is provided with sound output port 11, and input disk 4 and output The disks 1 are fastened together and fixed by bolts 2. The airflow input port 41 and the sound output port 11 are on the same center line. The sounding disk 3 is set between the input disk 4 and the output disk 1. There are gaps in between. The thickness of the sounding disc is 4.5-5.5 mm, and the gaps between the sounding disc, the input disc and the output disc are all less than 0.2 mm, and smooth air passages are formed inside the input disc 4 and the output disc 1 . The center of the sounding disk 3 is provided with a central hole, and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com