Battery equalizer formed by multi-winding transformer

A multi-winding transformer and transformer technology, applied in charge equalization circuit, arrangement of multiple synchronous batteries, parallel conversion of batteries, etc., can solve the problems of reduced conversion efficiency, inability to reset the magnetic core, and failure of the magnetic reset circuit to achieve the cost. Low, simple circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

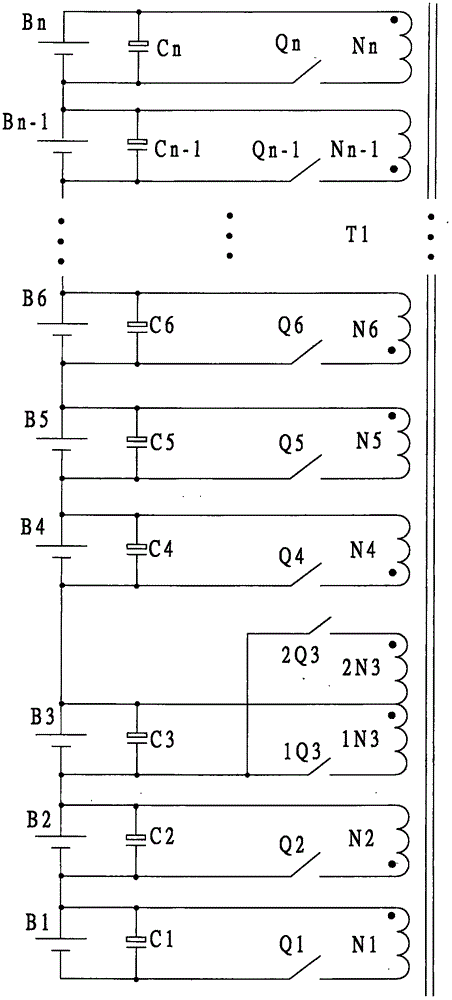

[0020] Embodiment 1, a single-transformer equalizer composed of a single-transistor forward circuit and a complementary push-pull circuit

[0021] Such as figure 1 As shown, the turns of each winding of the transformer T are all the same, that is, N1=N2=1N3=2N3=N4=N5=. . . =Nn, a single-transistor forward circuit is connected to the back of each battery, and a complementary push-pull circuit is connected to the back of the B3 battery; all switch tubes, Q1, Q2, 1Q3, 2Q3, Q4, Q5. . . Qn can be MOS tube, IGBT, etc.

[0022] It can be seen from the figure that the complementary push-pull circuit is composed of two single-tube forward circuits, and the corresponding winding directions of the two single-tube forward circuits are opposite.

[0023] According to the classification of the two winding directions of the transformer winding, all corresponding switching tubes are divided into two groups: group A switching tubes and group B switching tubes. Group A switching tubes ar...

Embodiment approach 2

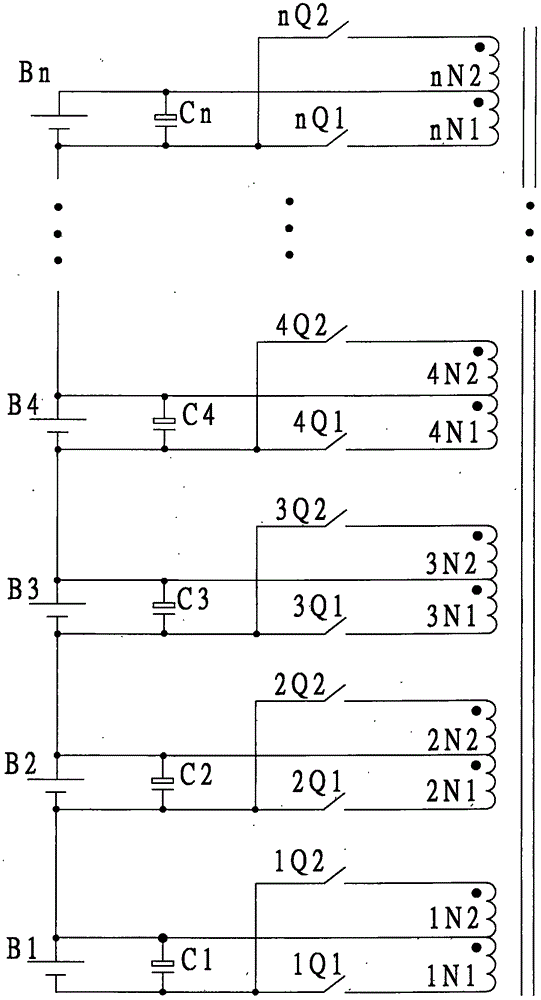

[0032] Embodiment 2, a single-transformer equalizer composed of complementary push-pull circuits

[0033] In order to further improve the balancing ability, the figure 1 The single-transistor forward circuits in the circuit are all changed into complementary push-pull circuits, and the equalization ability is doubled, such as figure 2 As shown, the number of turns of all windings in the figure is the same, that is, 1N1=-1N2=2N1=2N2=3N1==3N2=4N1=. . . =nN1=nN2; all switching tubes 1Q1, 1Q2, 2Q1, 2Q2, 3Q1, 3Q2. . . nQ1 and nQ2 can use MOS tubes, IGBTs, etc.

[0034] According to the classification of the two winding directions of the transformer winding, the switching tubes connected in series with the windings are divided into two groups: group A switching tubes and group B switching tubes. Group A switching tubes Q1, 2Q1, 3Q1, 4Q1. . . nQ1 is turned on and off at the same time; group B switching tubes Q2, 2Q2, 3Q2, 4Q2. . . nQ2 is turned on and off at the same ti...

Embodiment approach 3

[0041] Embodiment 3, multi-transformer equalizer composed of single-transistor forward and complementary push-pull circuits

[0042] For the case of a large number of batteries connected in series, the required number of coils cannot be wound on one magnetic core. In order to solve this problem, such as image 3 As shown, the equalizer uses multiple identical transformers, and the total number of transformers is m. Each transformer is added with a secondary winding Ns with the same number of turns on the basis of the transformer used in "Embodiment 1", and all transformers The secondary windings Ns of the transformer are all connected in parallel according to the principle of parallel connection of terminals with the same name; the composition characteristics of each transformer are: except for the added secondary coil Ns, the number of turns of all other windings is the same. All switching tubes can be MOS tubes, IGBTs, etc.

[0043] The working principle of the circuit is b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com