Preparation method of hollow graphene ball/sulfur composite material

A graphene ball, composite material technology, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve the problems of high self-discharge rate, low coulombic efficiency, poor cyclability of lithium-sulfur batteries, etc. Achieving the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Preparation of silica nanospheres: Dissolve 1.6mL tetraethylorthosilicate (TEOS) in 44mL absolute ethanol as liquid A. Dissolve 10 mL of ammonia water in 44 mL of absolute ethanol as solution B. Dissolve 2 mL of tetraethylorthosilicate (TEOS) in 88 mL of absolute ethanol as solution C.

[0029] Add liquid A and liquid B into a three-necked flask with mechanical stirring and start stirring at the same time, the rotation speed is about 350r / min. After 30 minutes of reaction, add 8mL ammonia water from the side port of the three-necked flask, and react for 5-10 minutes. Then add liquid C and continue the reaction for 2h.

[0030] After the reaction, the solid phase was taken by centrifugation and washed with deionized water to obtain 0.3 g of silica nanospheres.

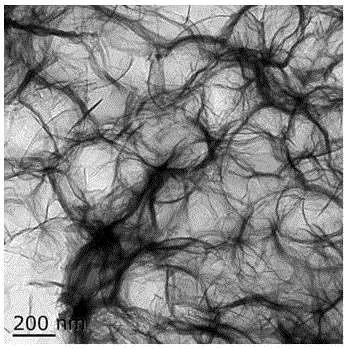

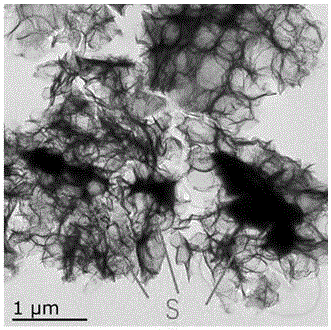

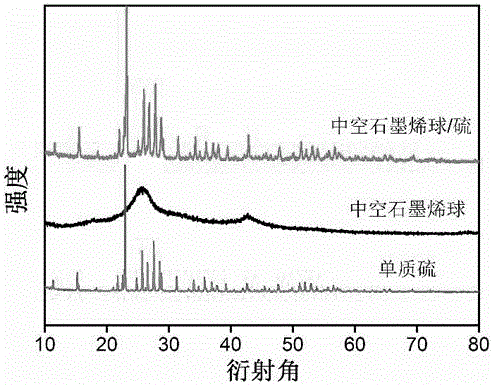

[0031] 2) Preparation of hollow graphene spheres: Pour 0.2 g of the prepared silica nanospheres into 50 mL of deionized water for ultrasonic dispersion, then transfer them into a beaker, and then add 250 mg ...

Embodiment 2

[0034] 1) Preparation of silica nanospheres: Dissolve 3.2mL tetraethylorthosilicate (TEOS) in 88mL absolute ethanol as solution A. Dissolve 20mL of ammonia water in 88mL of absolute ethanol as solution B. Dissolve 4 mL of tetraethylorthosilicate (TEOS) in 176 mL of absolute ethanol as solution C.

[0035] Add liquid A and liquid B into a three-necked flask with mechanical stirring and start stirring at the same time, the rotation speed is about 350r / min. After 30 minutes of reaction, add 8mL ammonia water from the side port of the three-necked flask, and react for 5-10 minutes. Then add liquid C and continue the reaction for 2h.

[0036] After the reaction, the solid phase was taken by centrifugation and washed with deionized water to obtain 0.6 g of silica nanospheres.

[0037]2) Preparation of hollow graphene spheres: Pour 0.4g of prepared silica nanospheres into 100mL of deionized water for ultrasonic dispersion, then transfer them into a beaker, and then add 500mg of cet...

Embodiment 3

[0040] 1) Preparation of silica nanospheres: Dissolve 4.8mL tetraethylorthosilicate (TEOS) in 132mL absolute ethanol as liquid A. Dissolve 30mL ammonia water in 132mL absolute ethanol as solution B. Dissolve 6 mL of tetraethylorthosilicate (TEOS) in 264 mL of absolute ethanol as solution C.

[0041] Add liquid A and liquid B into a three-necked flask with mechanical stirring and start stirring at the same time, the rotation speed is about 350r / min. After 30 minutes of reaction, add 8mL ammonia water from the side port of the three-necked flask, and react for 5-10 minutes. Then add liquid C and continue the reaction for 2h.

[0042] After the reaction, the solid phase was taken by centrifugation and washed with deionized water to obtain 0.9 g of silica nanospheres.

[0043] 2) Preparation of hollow graphene spheres: Pour 0.5g of prepared silica nanospheres into 150mL of deionized water for ultrasonic dispersion, then transfer them into a beaker, and then add 750mg of cetyltri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com