Low-cost production technology of COB packaging devices

A technology for packaging devices and production processes, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of high mold opening costs, low efficiency, poor flexibility, etc., and achieve easy mass production, reduce production costs, The effect of increasing the shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The low-cost production process of the COB packaging device of the present invention, the steps are as follows,

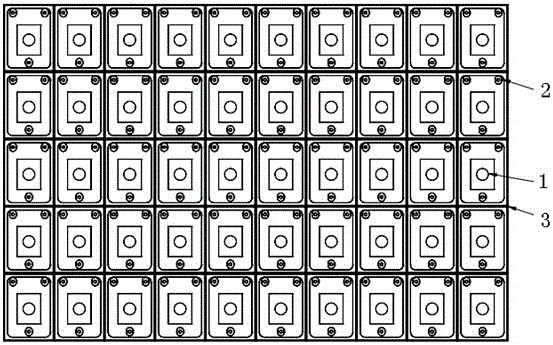

[0020] 1) According to the final dimensions of the COB packaged device to be obtained, select a PCB board of an appropriate size (the PCB board is composed of a fiber layer in the middle and copper layers on both sides), so that the PCB board can be separated from each corresponding to all COB packaged devices. packaging unit;

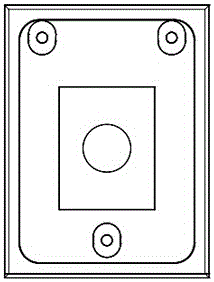

[0021] 2) According to the PCB board patterning process, the packaging unit corresponding to the COB package device to be obtained is obtained by patterning on the PCB board; any package unit and the surrounding adjacent packaging units are formed through a patterning process to facilitate subsequent cutting Cutting guide groove 3; each package unit forms a chip accommodation cavity and ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com