Microprocessor control electro-hydraulic servo load-shear test machine

An electro-hydraulic servo and microcomputer-controlled technology, applied in the field of testing machines, can solve the problems of unstable loading rate of testing machines, unsatisfactory testing methods, unstable testing data, etc. , the effect of excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

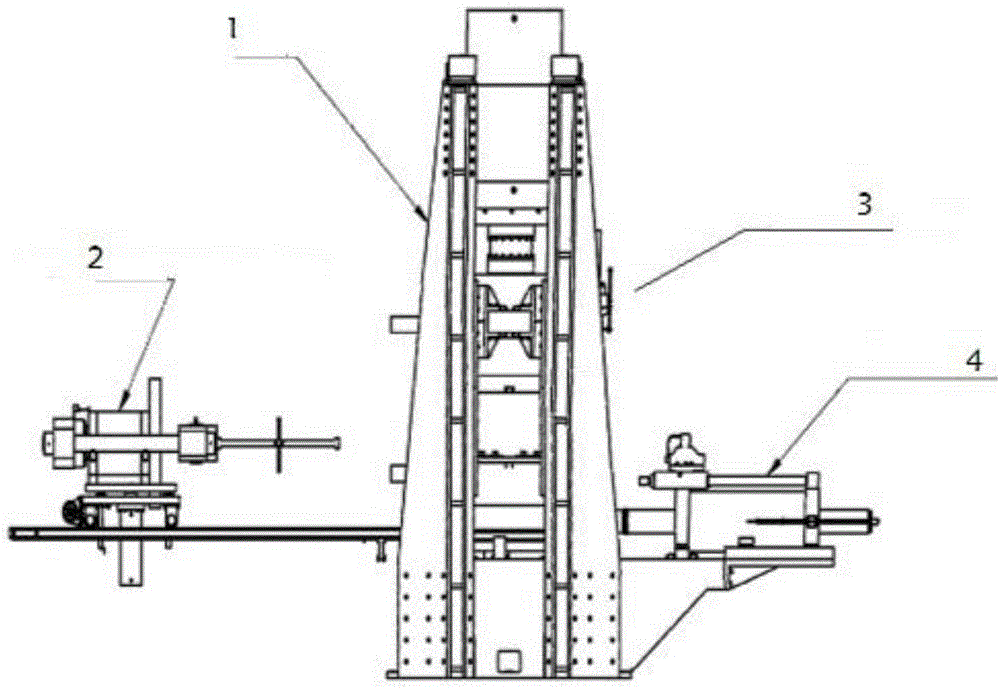

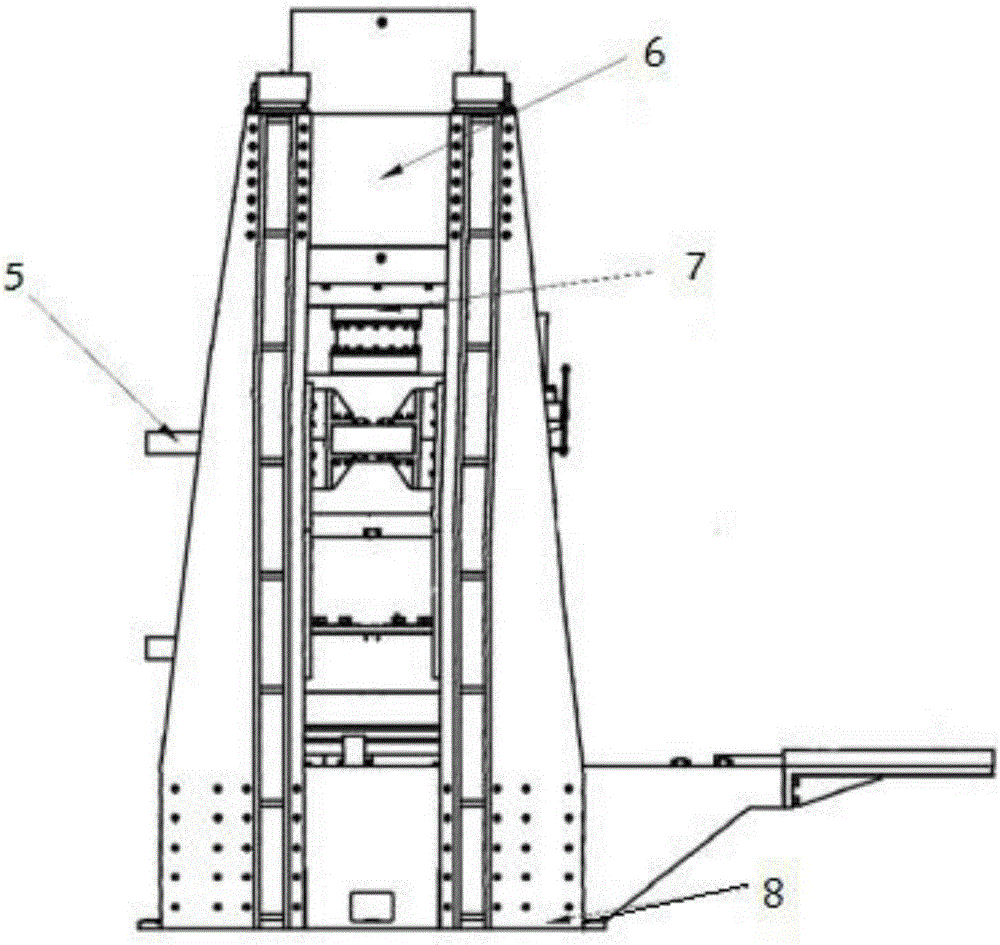

[0031]The microcomputer-controlled electro-hydraulic servo compression-shear testing machine includes a host machine 1, a horizontal dynamic single-shear loading mechanism 4, a horizontal static double-shear loading mechanism 2, a rotation angle measurement system 3, a hydraulic system and a control system, and is characterized in that: the host machine 1 It includes a column 9, a main oil cylinder 7, an upper plate 5, a fixed base 8, and a fixed beam 6. The column 9 is a four-column structure, and the fixed beam 6 is fixed on the top of the four columns through a combination of snap rings and nuts. The main oil cylinder 7 Through the fixed beam 6, the piston is fixed on the upper platen 5, and a load sensor I is installed between the upper platen 5 and the piston of the main o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com