Method for evaluating the reliability of ball screw pair by accelerated test

A ball screw pair, acceleration test technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of increased stress, lack of calculation, ball screw pair fault classification and unclear weighting, etc., to improve accuracy, The effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

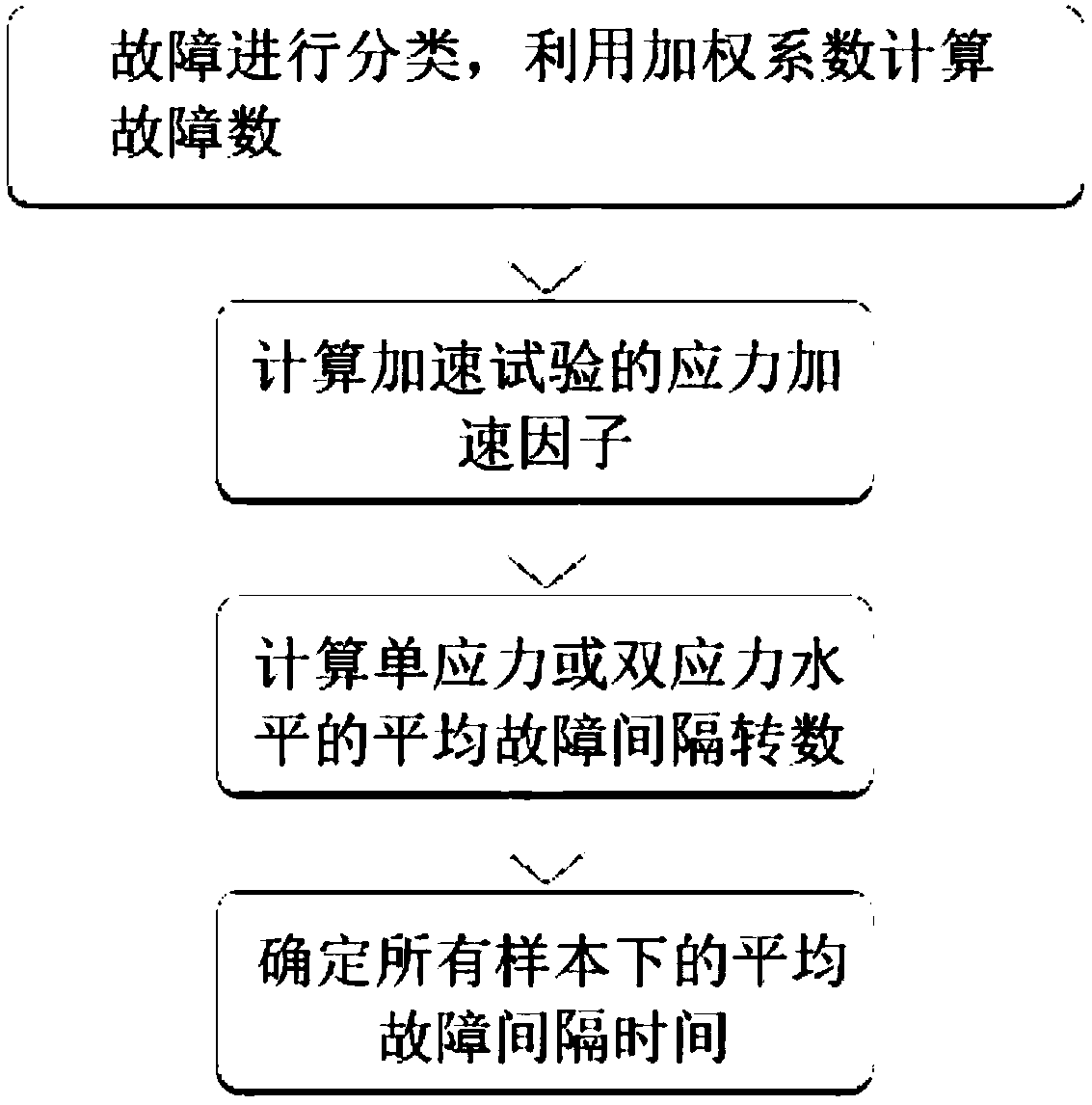

[0044] The accelerated test evaluation method for the reliability of the ball screw pair includes the following contents:

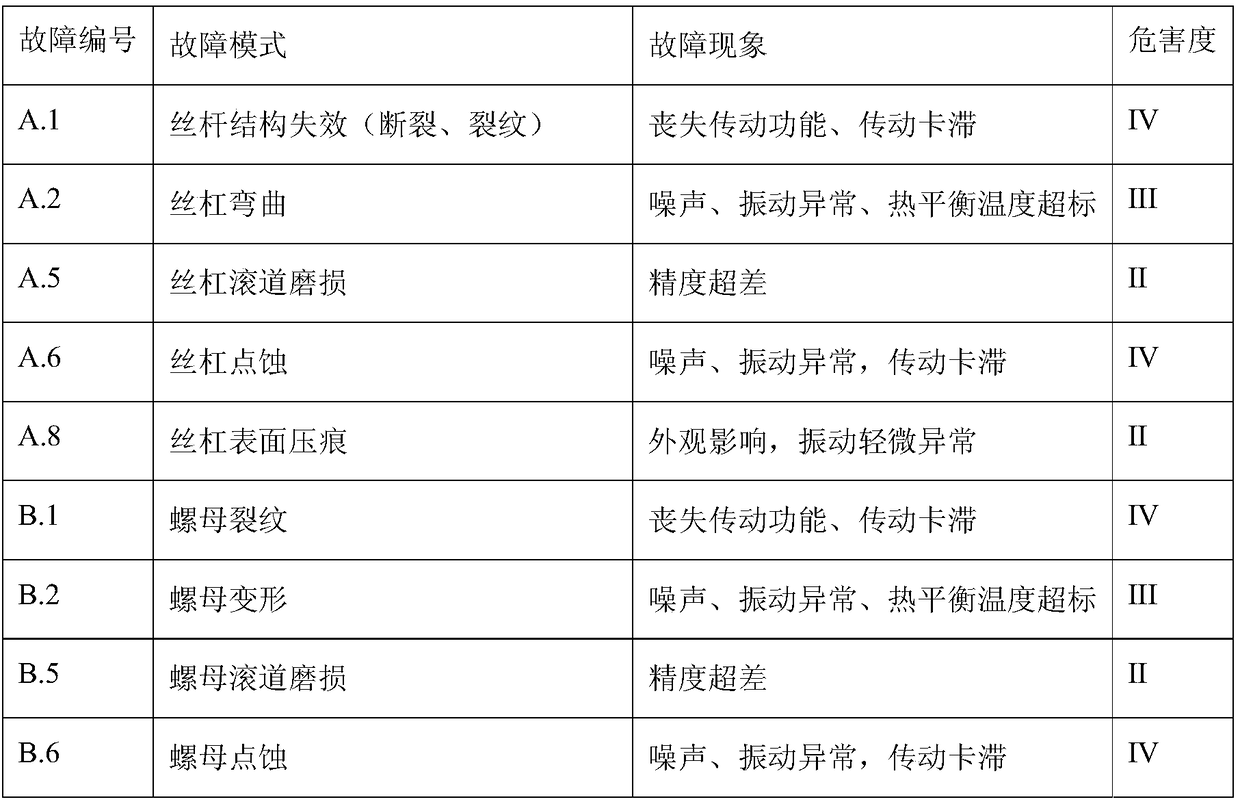

[0045] Determine the fault classification and termination conditions of the reliability test of the ball screw pair:

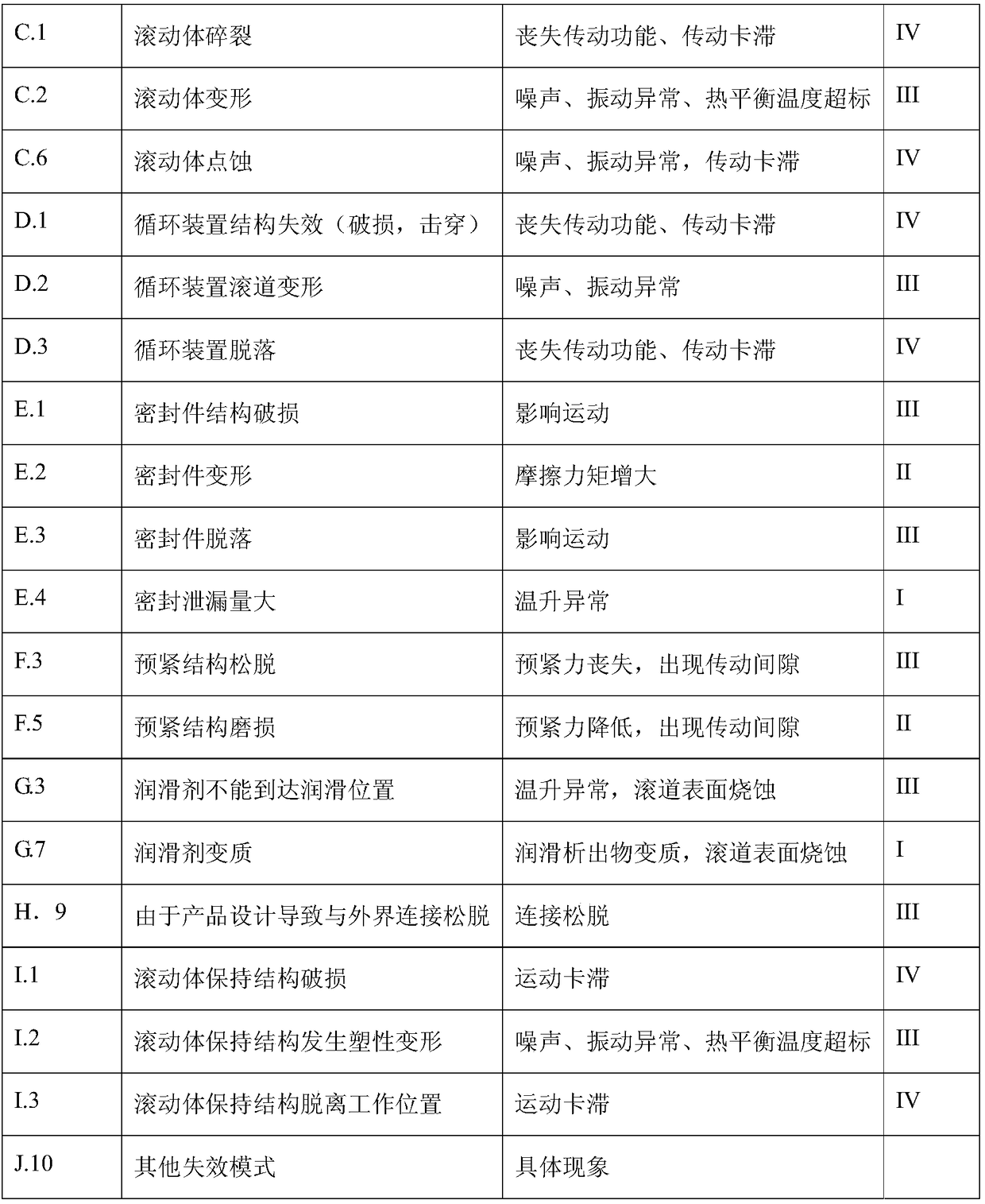

[0046] Timing censored reliability test method, the loading force is 5% Ca and 10% Ca respectively, the test cut-off revolutions are set to 1.2 million revolutions, and the rotational speed is 500rpm. Fault data: The number of revolutions (number of revolutions / fault number) of the three samples: 1.03 million revolutions / F5; 1.42 million revolutions / B5; 1.58 million revolutions / F5; 2.36 million revolutions / F5. All the samples produced irreparable faults when completing the specified number of revolutions, and there were 3 samples in total, ie m=3. All sample failures are summarized in Table 4 below:

[0047] Table 4 Reliability Accelerated Test Fault Statistics Table

[0048]

[0049] 1. Stress acceleration factor calculation:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com