Level i angle monitoring device

A leveling instrument and leveling technology, applied in the direction of hydrostatic pressure, etc., can solve the problems of consuming energy and time of surveyors, low measurement accuracy, and reduced accuracy of measurement results, so as to improve operation accuracy and work efficiency, improve the level of intelligence, and ensure The effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

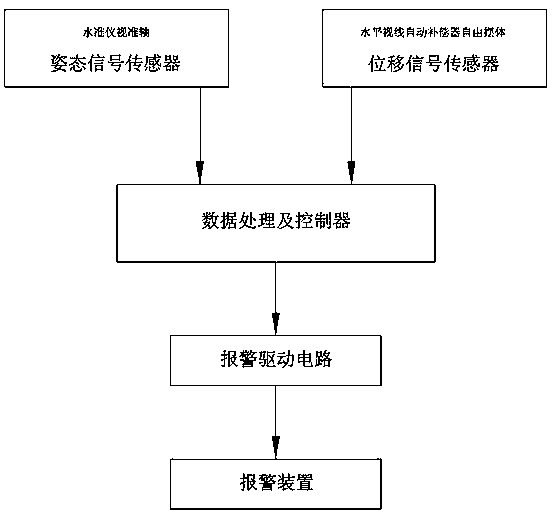

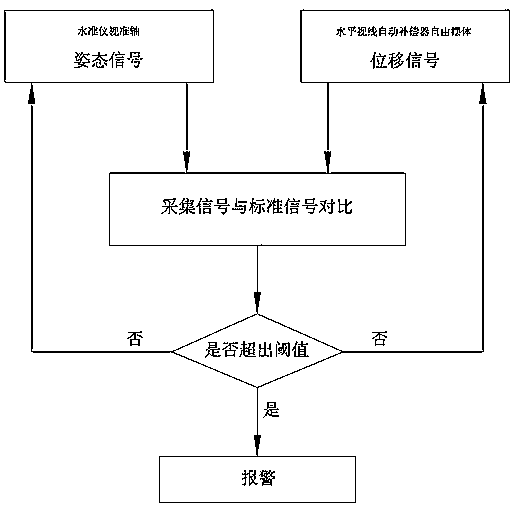

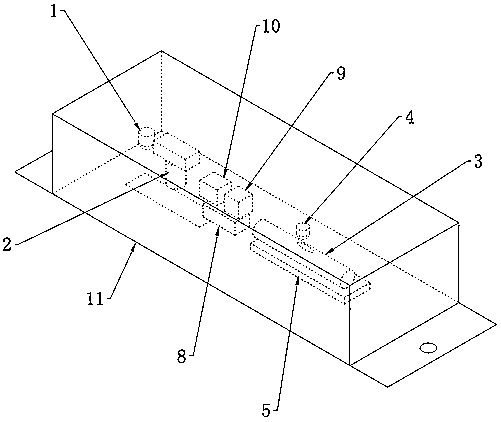

[0017] The block diagram of the circuit is as figure 1 Shown: the leveling instrument collimation axis attitude signal sensor and the horizontal line of sight automatic compensator free pendulum body displacement signal sensor are provided, the output of the leveling instrument line of sight attitude signal sensor and the level line of sight automatic compensator free pendulum body displacement signal sensor are all consistent with The data processing is connected with the controller 8 , and the output of the data processing and the controller 8 is connected with the alarm device 10 through the alarm driving circuit 9 . The specific structure is as image 3 As shown: there is a casing 11 with an opening, and the horizontal line of sight automatic compensator free swing body composed of the first light source 1 (LED) and the first image acquisition device 2 (CCD) is fixed on the opening side of the casing 11 For the displacement signal sensor, a tubular vial 3 is fixed at othe...

Embodiment 2

[0025] Such as Figure 7 Shown: the structure is basically the same as that of embodiment 1, the difference is that the attitude signal sensor of the collimation axis of the leveling instrument adopts the existing electronic level bubble (resistive, capacitive, inductive and photoelectric) 6, which is installed on the leveling instrument, the first An image acquisition device 2 is connected with the output of the electronic vial 6 and the data processing and controller 8 .

[0026] Use working process with embodiment 1.

Embodiment 3

[0028] Such as Figure 8 As shown: the structure is basically the same as that of Embodiment 1, the difference is that the attitude signal sensor of the collimation axis of the leveling instrument adopts the existing inclination sensor 7, such as the MEMS high-precision inclination sensor (SCA103T-D04 of Finland VTI Company), etc., and is installed horizontally on the On the leveling instrument, the output of the first image acquisition device 2 and the inclination sensor 7 is connected with the data processing and controller 8 . When the inclination sensor is in a static state, the output value is the voltage value converted from the components of the gravitational acceleration g in each direction. When the angle of the level changes, the components of the gravitational acceleration g in each direction change, so that the output voltage value changes, that is The sensor signal of the horizontal state of the collimation axis of the leveling instrument.

[0029] Use working pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com