Central hot water recycling system

A hot water circulation and central technology, applied in the field of solar thermal energy utilization, can solve problems such as waste of resources, limited roof area, user troubles, etc., to achieve the effect of ensuring freedom and full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

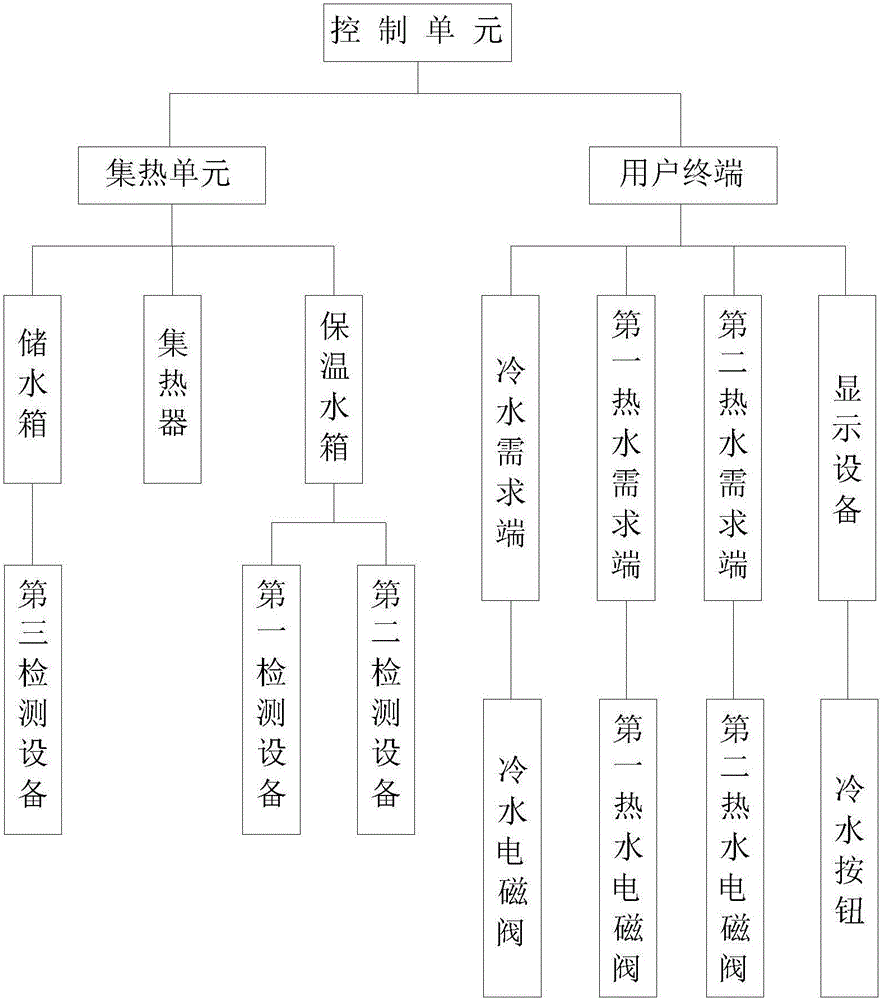

[0022] Such as figure 1 as shown, figure 1 It is a central hot water recycling system proposed by the present invention.

[0023] refer to figure 1 , the central hot water recycling system proposed by the present invention includes: a plurality of heat collecting units, a plurality of user terminals, and a control unit; the heat collecting units correspond to the user terminals one by one;

[0024] Any heat collecting unit among the plurality of heat collecting units includes a heat collector, a thermal insulation water tank and a water storage tank; the heat collector is connected with the pipeline of the thermal insulation water tank; There is a water valve; the heat collector is used to collect the heat energy of solar radiation, and use the above heat energy to heat the water in the heat preservation water tank; the heat preservation water tank is provided with a water inlet and a water outlet, and the water inlet is connected with a water inlet pipe and the water outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com