Large-diameter pipeline installation device and pipeline installation method utilizing same

A technology for large-diameter pipelines and installation devices, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc. Fast installation and the effect of solving industry problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

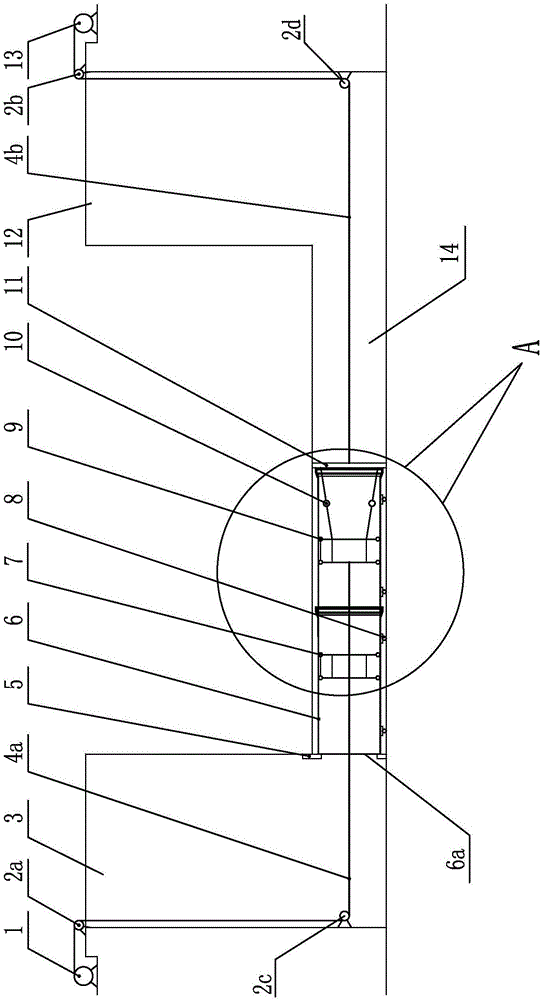

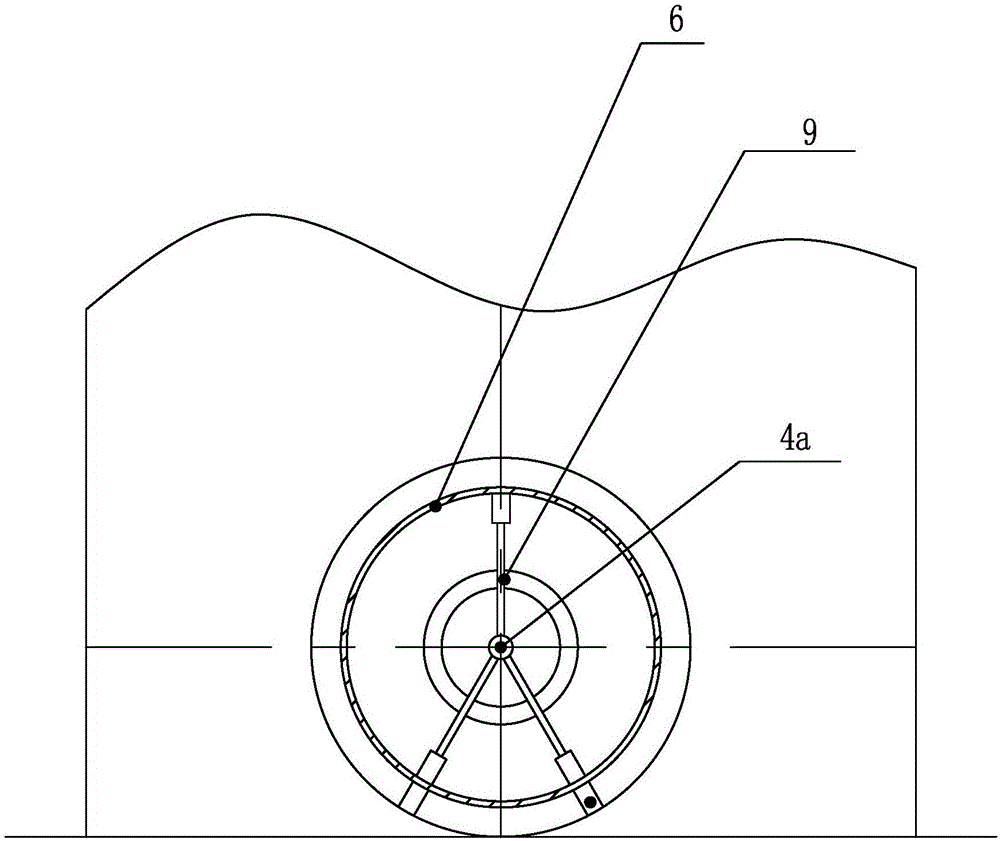

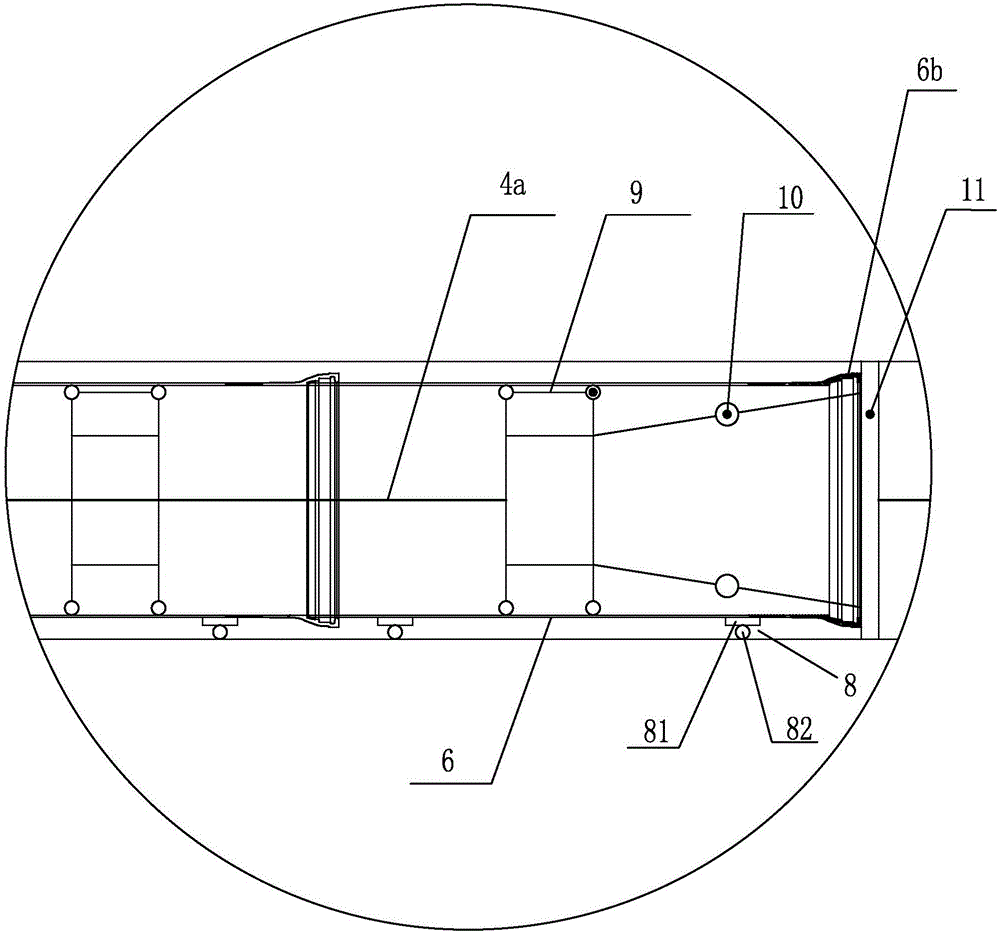

[0034] Such as Figure 1 to Figure 3As shown, the takeover well 3 is used to accept the ductile iron pipe 6 lowered and installed from the lower pipe well 12 . The main hoisting device 1 located on the ground of the takeover shaft 3 and the auxiliary hoisting device 13 located on the ground of the lower pipe shaft 12 . The right side of the main hoisting device 1 and the left side of the auxiliary hoisting device 13 are respectively provided with a left fixed pulley 2 a and a right fixed pulley 2 b opposite to each other. The connecting pipe shaft 3 is connected with the bottom of the lower pipe shaft 12 to form a tunnel 14. The left and right fixed pulleys 2c and 2d are arranged symmetrically on the inner walls of the left and right ends of the tunnel 14 along its axial direction. To connect, the right end is connected with the wire rope end coupler 9 after bypassing the left fixed pulley 2a and the lower left fixed pulley 2c successively. Also includes auxiliary wire rope ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com